Stable compound lithium ion battery negative electrode material alpha-Ga2O3 and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in the field of electrochemical power supply, can solve the problems of unfamiliar lithium ion diffusion in electrical properties, etc., and achieve the effects of simple and controllable method, good repeatability, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

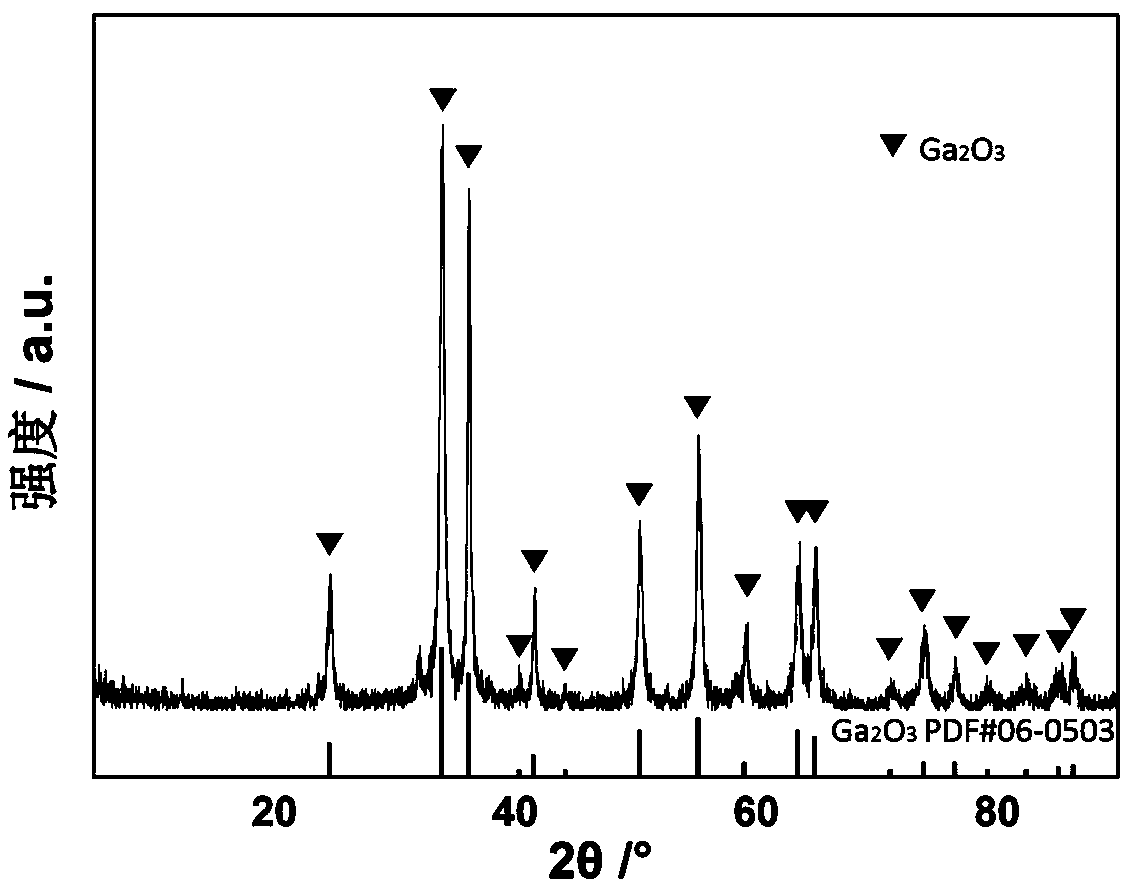

[0021] First weigh 5 mmol of gallium nitrate, 5 mmol of hexamethylenetetramine, 0.5 g of sodium sulfate, and 0.1 g of citric acid in a 50 ml small beaker, add deionized water to the small beaker, and stir for 20 minutes until the medicines are completely dissolved. Transfer the solution to a hydrothermal liner, add deionized water to 80% of the volume of the liner, fix the liner with an external scale, and heat it in a blast oven at 120°C for 12 hours. The samples were obtained by sintering in air at 400°C in a tube furnace for 10 h after drying in medium temperature. The prepared sample was analyzed by XRD pattern, as figure 1 As shown, the diffraction peaks (▼) and α-Ga 2 o 3 (XRD card JCPDS, NO. 06-0503) corresponds, indicating that the successful preparation of α-Ga 2 o 3 Material. The samples were characterized by SEM, by figure 2 It can be seen that it consists of micron squares with a length of 1-1.5 μm and a width and height of 200-800 nm. The α-Ga obtained b...

Embodiment 2

[0023] First weigh 5 mmol of gallium nitrate, 5 mmol of hexamethylenetetramine, 0.5 g of sodium sulfate, and 0.1 g of citric acid in a 50 ml small beaker, add deionized water to the small beaker, and stir for 20 minutes until the medicines are completely dissolved. Transfer the solution to a hydrothermal liner, add deionized water to 80% of the volume of the liner, fix the liner with an external scale, and heat it in a blast oven at 160°C for 12 hours. α-Ga 2 o 3 . The battery was assembled according to the method of Example 1. Figure 4 It shows that the α-Ga prepared in Example 2 2 o 3 Under the current density of 0.15 A / g, the first charge and discharge specific capacities of the electrodes are 776, 1331 mAh / g, and after 100 cycles, they are 82.8, 85.1 mAh / g.

Embodiment 3

[0025] First weigh 5 mmol of gallium nitrate, 5 mmol of hexamethylenetetramine, 1 g of sodium sulfate, and 0.1 g of citric acid in a 50 ml small beaker, add deionized water to the small beaker, and stir for 20 minutes until the medicines are completely dissolved. Transfer the solution to a hydrothermal liner, add deionized water to 80% of the volume of the liner, fix the liner with an external scale, and heat it in a blast oven at 200°C for 12 hours. α-Ga 2 o 3 . The battery was assembled according to the method of Example 1. Figure 5 It shows that the α-Ga prepared in Example 3 2 o 3 The first charge and discharge specific capacities of the electrode are 747.1 and 1338.7 mAh / g at a current density of 0.15 A / g, and 34.4 / 34.5 mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com