Kiln and method for converting chemical engineering hazardous waste sodium chloride into refined industrial salt

A technology for waste hazardous sodium chloride and industrial salt, applied in the chemical industry, alkali metal chloride, alkali metal halide purification, etc., can solve the problems of polluting resources, occupying a large area, land salinization, etc., and achieve saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

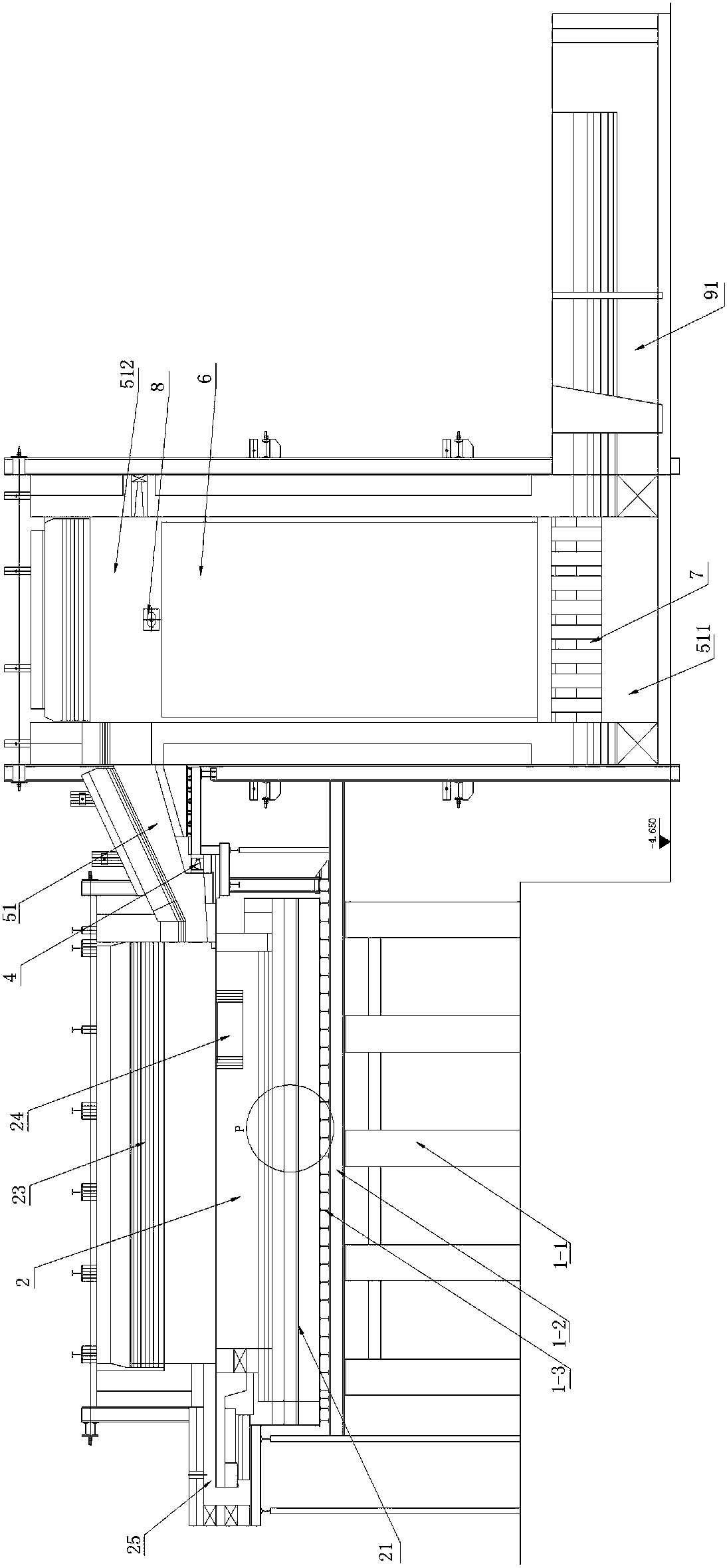

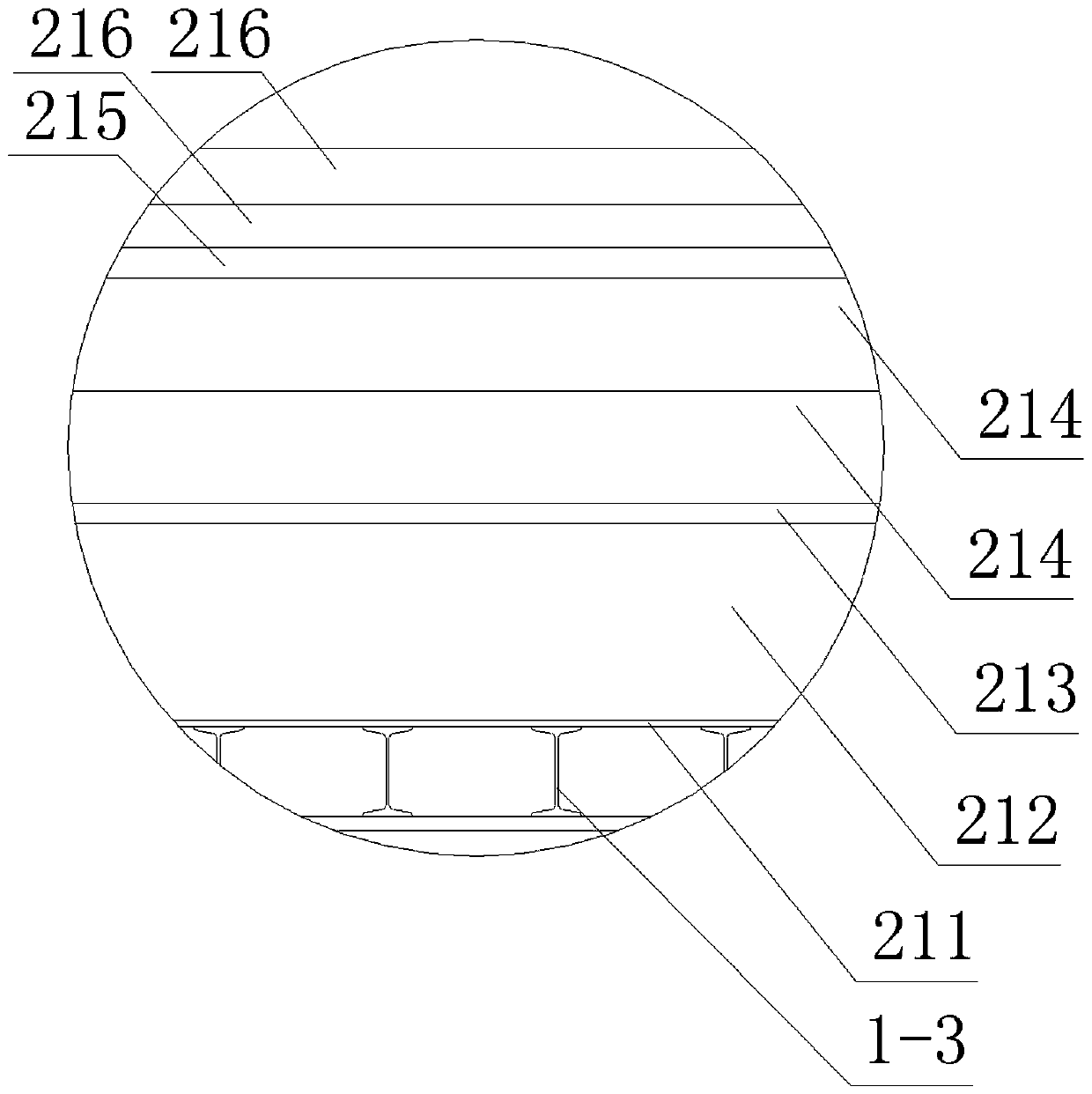

[0039] see Figure 1 to Figure 12 , a kind of kiln that converts chemical waste hazardous sodium chloride into refined industrial salt, including a kiln body including a melting pool 2, the melting pool 2 of the kiln body is provided with a feed port 24 and a discharge port 25, and It includes two independent dioxin removal chambers and two sets of combustion-supporting devices respectively connected to the two dioxin removal chambers, and the two dioxin removal chambers are respectively connected to the melting pool 2 of the kiln body through a small furnace. The first dioxin removal chamber 51 communicates with the melting pool 2 of the kiln body through the first small furnace 31, and the second dioxin removal chamber 52 communicates with the melting pool 2 of the kiln body through the second small furnace 32 connected. Each small furnace is provided with a first flamethrower 4, and the fire spraying direction of the first flamethrower 4 faces the inner cavity of the melti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com