Fluorine-lined ball valve with sealing piece protecting function

A protection function, fluorine-lined ball valve technology, applied in the field of fluorine-lined ball valves, can solve the problems of reducing sealing performance and service life, wear of fluorine-lined opening and closing parts and valve seats, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

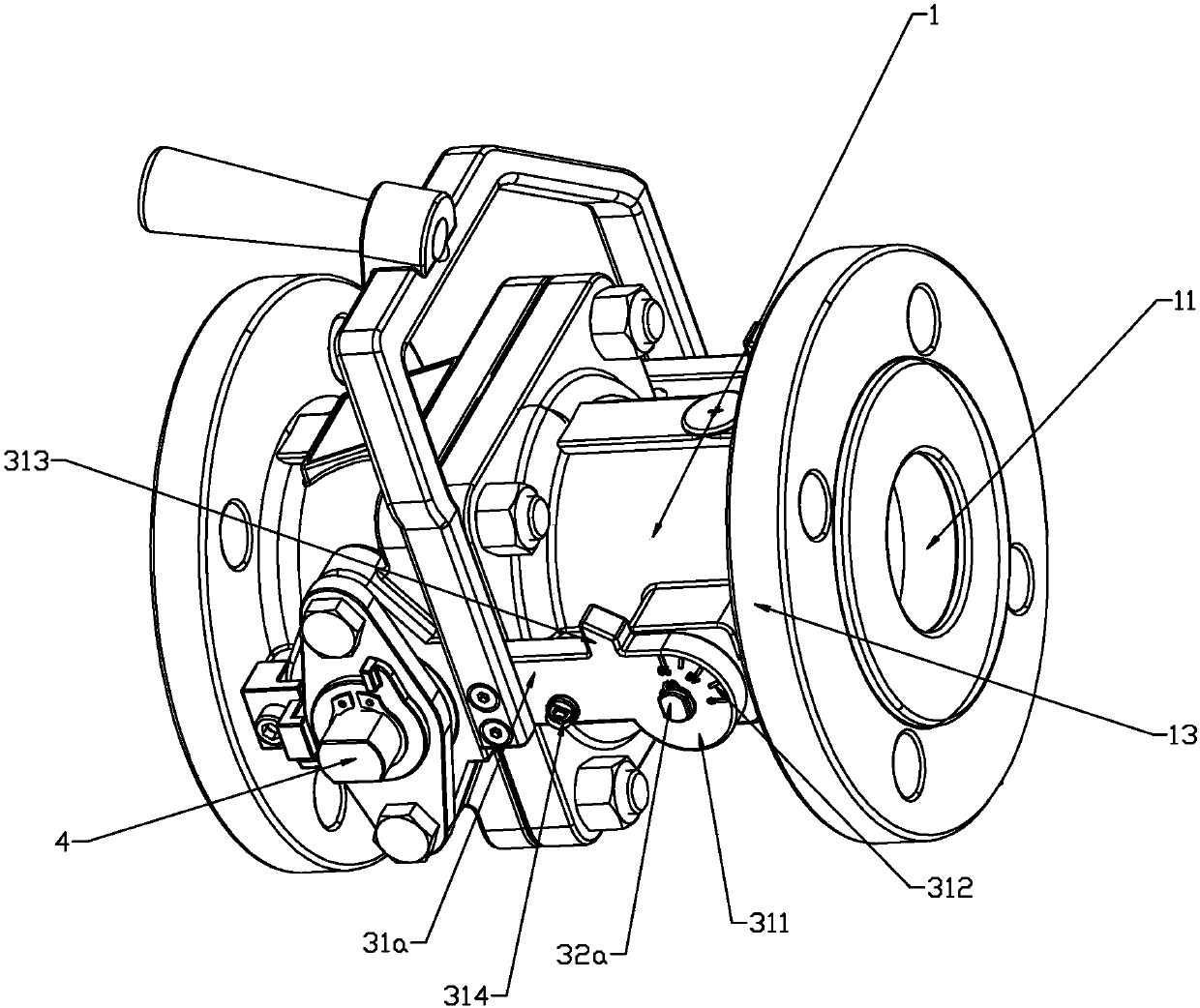

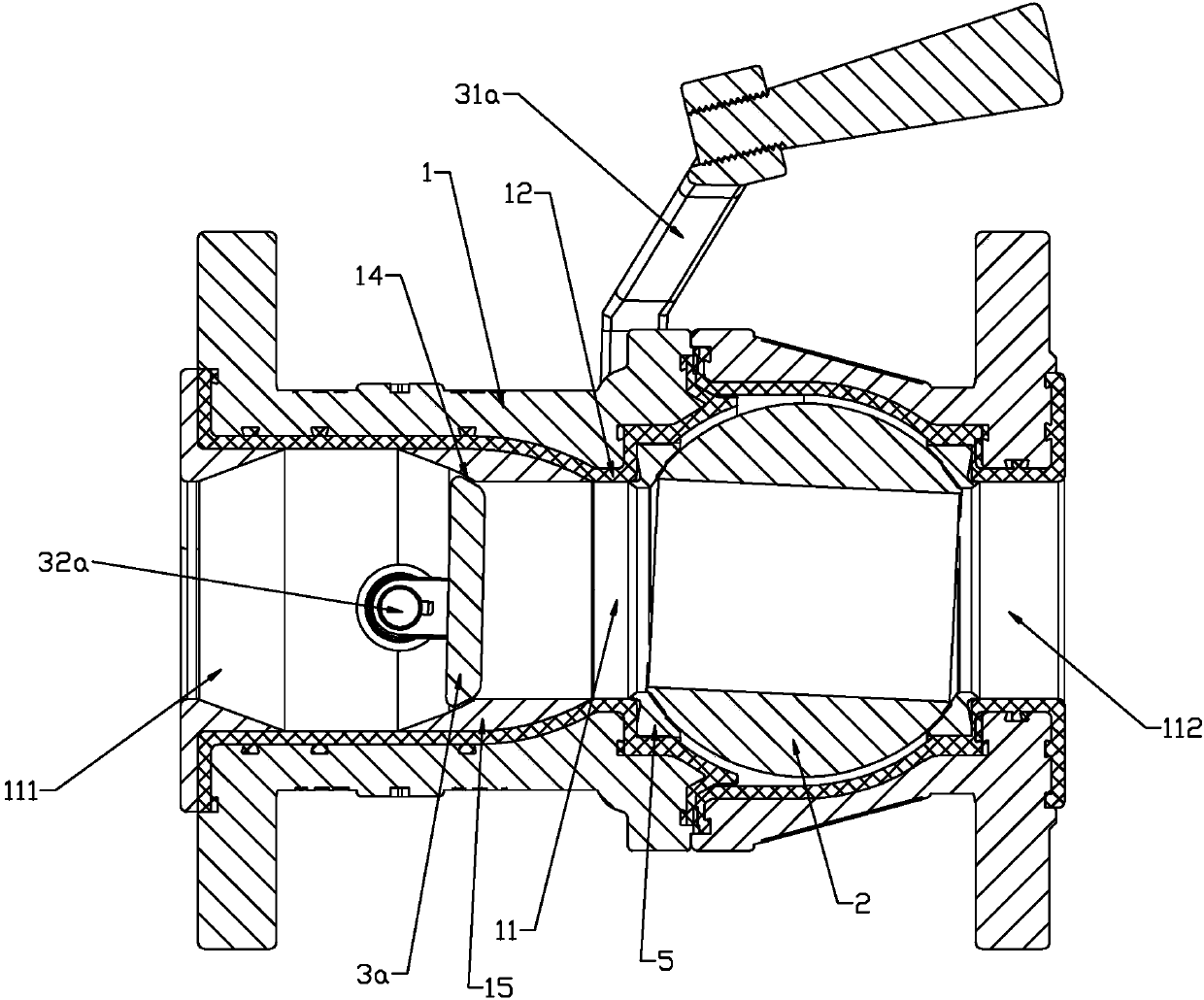

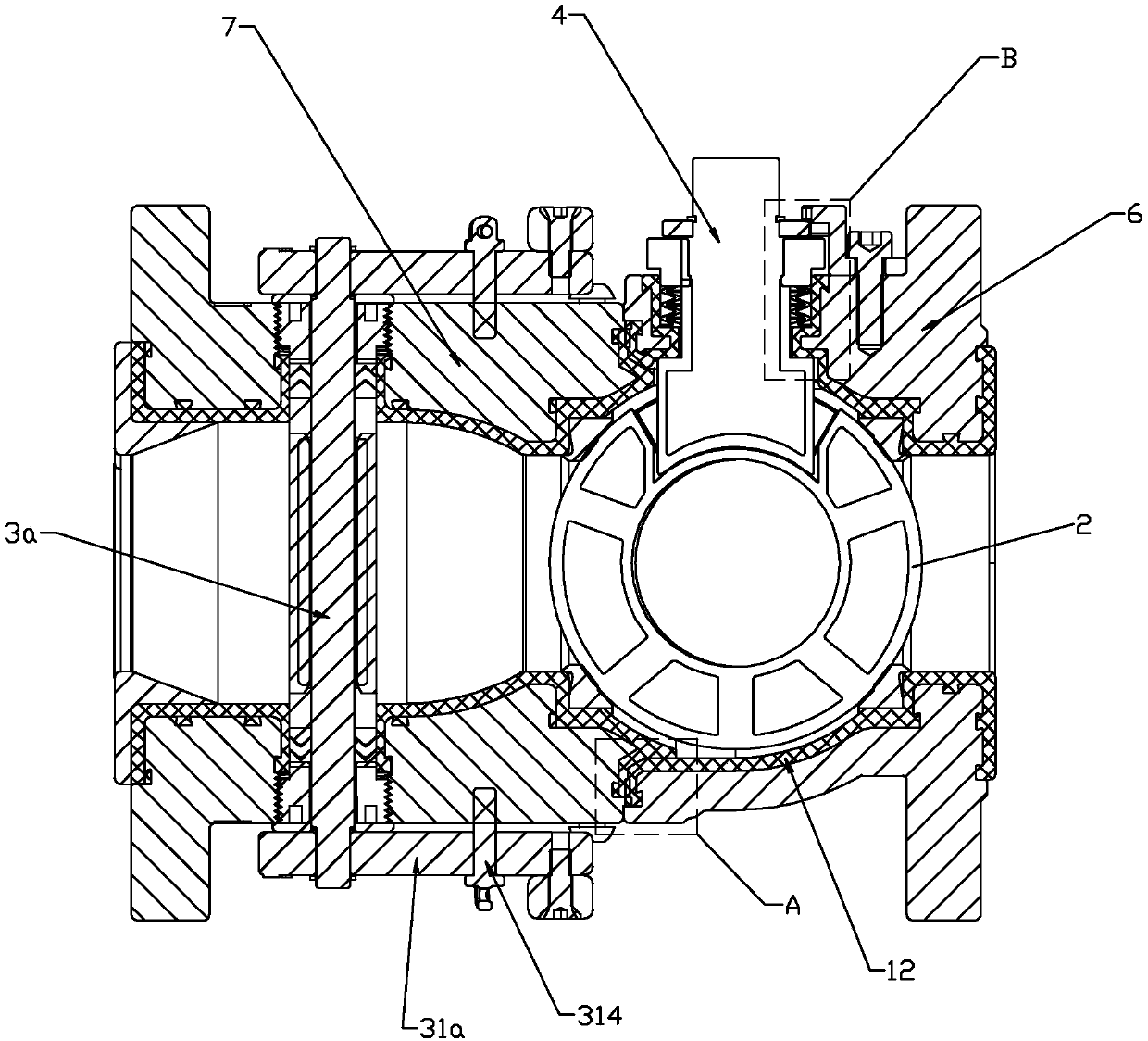

[0032] Such as figure 2 — Figure 10As shown, the present invention discloses a fluorine-lined ball valve with a seal protection function, which includes a valve body 1, a fluorine-lined ball 2, a valve stem 4 and a main valve seat 5. A flow channel 11 is arranged in the valve body 1, and the flow channel The inner wall of 11 is provided with a fluorine lining 12, and the valve stem 4 controls the action of the fluorine-lined sphere 2 to form the flow channel 11 to cut off and communicate. The inline end 111 connected to the tank truck and the outboard end 112 communicating with the outside world also include a granular material seal and an operating piece arranged on the flow channel 11 and between the inline end 111 and the fluorine-lined sphere 2, and the granular material seal Under the control of the operating part, the relative flow channel 11 has a first state and a second state. When the granular material seal is in the first state, the granular material freely passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com