A kind of dope dyed polyester fiber and its preparation method

A polyester fiber, dope dyeing technology, applied in the textile field, can solve the problems of poor compatibility of dyed polyester melt and deterioration of spinnability, achieve good spinnability, solve compatibility problems, and improve flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

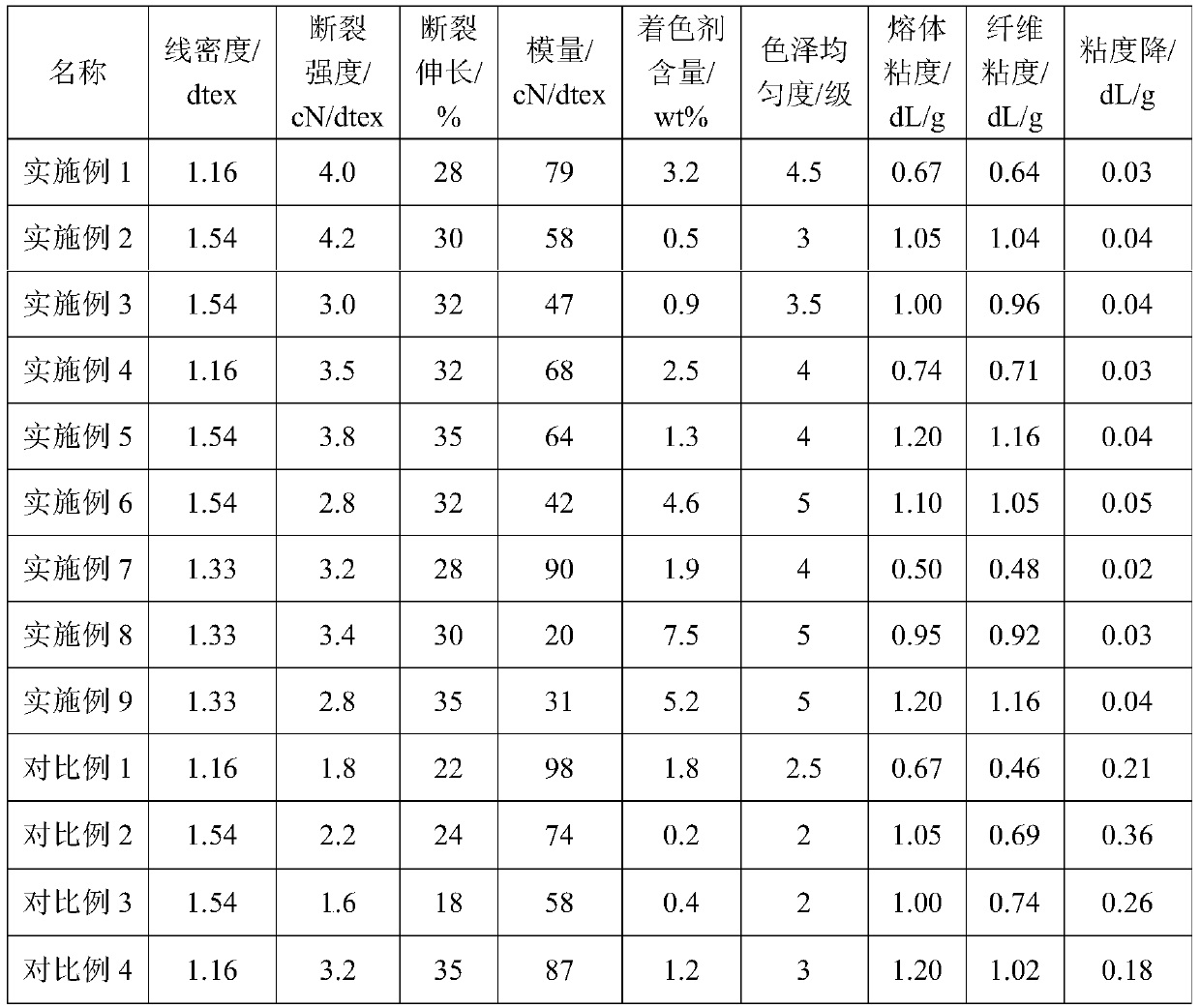

Examples

Embodiment 1

[0046] Add the colorant C.I. Solvent Red 135 and polybutylene adipate polyol with a molecular weight of 4000 into the coloring mother liquor preparation tank at a weight ratio of 30:70, and stir it under the condition that the preparation temperature is 150°C. The coloring agent C.I. solvent red 135 is fully dissolved in the polybutylene adipate polyol to obtain the coloring mother liquor with the content of the coloring agent C.I. solvent red 135 being 30 wt%. Then move the prepared coloring mother liquor into the coloring mother liquor supply tank for standby, wherein the supply temperature of the coloring mother liquor is 100°C.

[0047] Inject the ethylene terephthalate oligomer with a degree of polymerization of 5 from the esterification system into the above-mentioned colored mother liquor equivalent to 12 wt% of its mass and 0.05 wt% of antimony-based catalyst, and the material is homogenized by high shear After the pump is mixed evenly, it enters the pre-condensation s...

Embodiment 2

[0051] Add the colorant C.I. Solvent Red 168 and polyethylene succinate polyol with a molecular weight of 300 into the coloring mother liquor preparation tank at a weight ratio of 10:90, and stir to make The coloring agent C.I. solvent red 168 is fully dissolved in the polyethylene succinate polyol to obtain a coloring mother liquor with the content of the coloring agent C.I. solvent red 168 being 10 wt%. Then the prepared coloring mother liquor is moved into the coloring mother liquor supply tank for standby, wherein the supply temperature of the coloring mother liquor is 50°C.

[0052] Inject the above-mentioned colored mother liquor and 0.1wt% titanium series catalyst that are equivalent to its quality 5.3wt% in the butylene terephthalate oligomer that the degree of polymerization from the esterification system is 3, and the material is homogeneous through high shear After the chemical pump is mixed evenly, it enters the pre-condensation system for pre-condensation reaction...

Embodiment 3

[0056] Add the colorant C.I. Solvent Yellow 116 and polytrimethylene sebacate polyol with a molecular weight of 2000 into the coloring mother liquor preparation tank at a weight ratio of 10:90, and make the colorant C.I. Solvent Yellow 116 was fully dissolved in polytrimethylene sebacate polyol to obtain a coloring mother liquor with a colorant C.I. Solvent Yellow 116 content of 10 wt%. Then move the prepared coloring mother liquor into the coloring mother liquor supply tank for standby, wherein the supply temperature of the coloring mother liquor is 80°C.

[0057] Inject the propylene glycol terephthalate oligomer with a polymerization degree of 3 from the esterification system into the above-mentioned colored mother liquor equivalent to 10wt% of its mass and 0.2wt% of the titanium-based catalyst, and the materials are mixed by a high-shear homogenizing pump After uniformity, enter the precondensation system for precondensation reaction. The temperature of the precondensation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com