Fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder, and preparation method thereof

A nitrogen oxide, fluorescence enhancement technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems affecting the process of commercialization, the reduction of white LED efficiency, low fluorescence brightness, etc., and achieve chemical stability and thermal stability. Improve the effect of large-scale continuous production and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

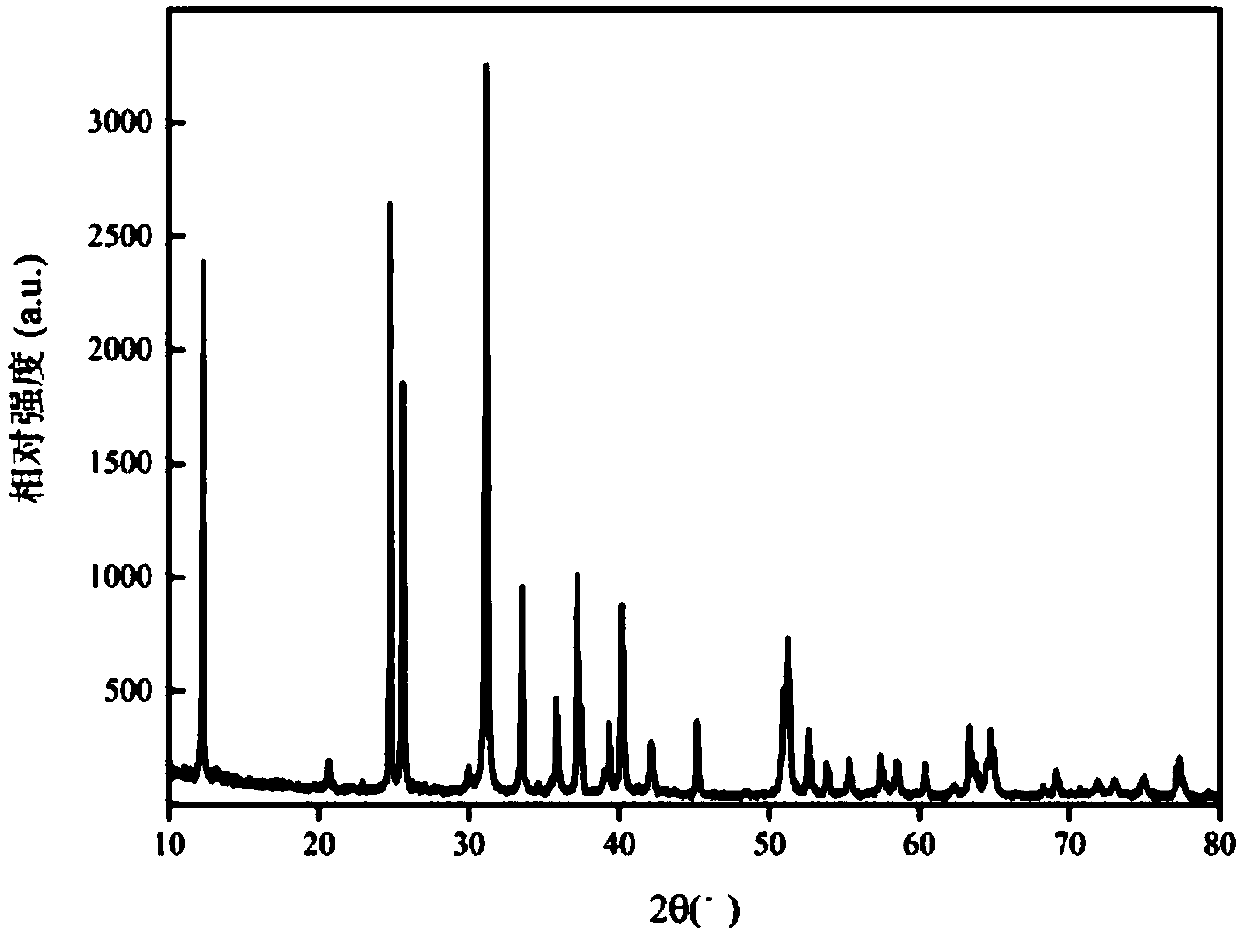

Image

Examples

preparation example Construction

[0040] The preparation method of the fluorescence-enhanced silicon-based oxynitride cyan fluorescent powder of the present invention comprises the following steps:

[0041] Step 1, according to the stoichiometric ratio of the precursor to be prepared, weigh the solid compound of Ba and / or the simple substance of Ba, the solid compound of Si and / or the simple substance of Si, the solid compound of Eu and / or the simple substance of Eu, the solid compound of M and / or M simple substance, R solid compound and / or R simple substance, A solid compound and / or A simple substance, after mixing the above materials evenly, the resulting mixture is sintered at 1100°C-1300°C for 2-6h in an atmosphere, and cooled After reaching room temperature, grind, obtain precursor (Ba 1-x'-y'-z'-m' m x' R y' A z' ) 2 SiO 4 :m'Eu 2+ , where x', y', z' and m' are mole fractions, and the range of values is x'≤x, y'≤y, z'≤z, m'≤m;

[0042] In step 1, when Ba, Si, Eu, M, R, and A elements are added ...

Embodiment 1

[0054] (Ba 0.94 Dy 0.01 Li 0.01 )O 0.5SiO 2 0.5Si 3 N 4 :0.04Eu 2+ Preparation of:

[0055] Step 1, according to chemical formula Ba 1.92 SiO 4 :0.08Eu 2+ The stoichiometric ratio of BaCO 3 , SiO 2 and Eu 2 o 3 , after mixing the above materials evenly, the resulting mixture was sintered at 1200°C under a reducing atmosphere of hydrogen for 6h, cooled to room temperature and then ground to obtain the precursor Ba 1.92 SiO 4 :0.08Eu 2+ ;

[0056]Step two, according to (Ba 0.94 Dy 0.01 Li 0.01 )O 0.5SiO 2 0.5Si 3 N 4 :0.04Eu 2+ The stoichiometric ratio, weigh the precursor 0.5171g, Si powder 0.1264g, Eu 2 o 3 0.0013g, Li 2 CO 3 0.0011g, Dy 2 o 3 0.0056g, put the weighed material into a mortar and grind and mix to obtain a uniform mixture powder, place the mixture powder in a pressure furnace, heat up to 1400°C and sinter under a high-purity nitrogen atmosphere of 1MPa for 6h, After cooling to room temperature, grind to obtain silicon-based oxynitride...

Embodiment 2-39

[0058] The preparation process is the same as that of Example 1. The chemical formula of the cyan phosphor, the chemical formula of the precursor, the raw materials used, and the preparation process conditions of each example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com