Low-temperature liquid medium

A low-temperature liquid and medium technology, applied in the field of low temperature, can solve the problems of easy volatilization, high viscosity, too large, etc., and achieve the effect of low boiling point and low volatilization under normal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

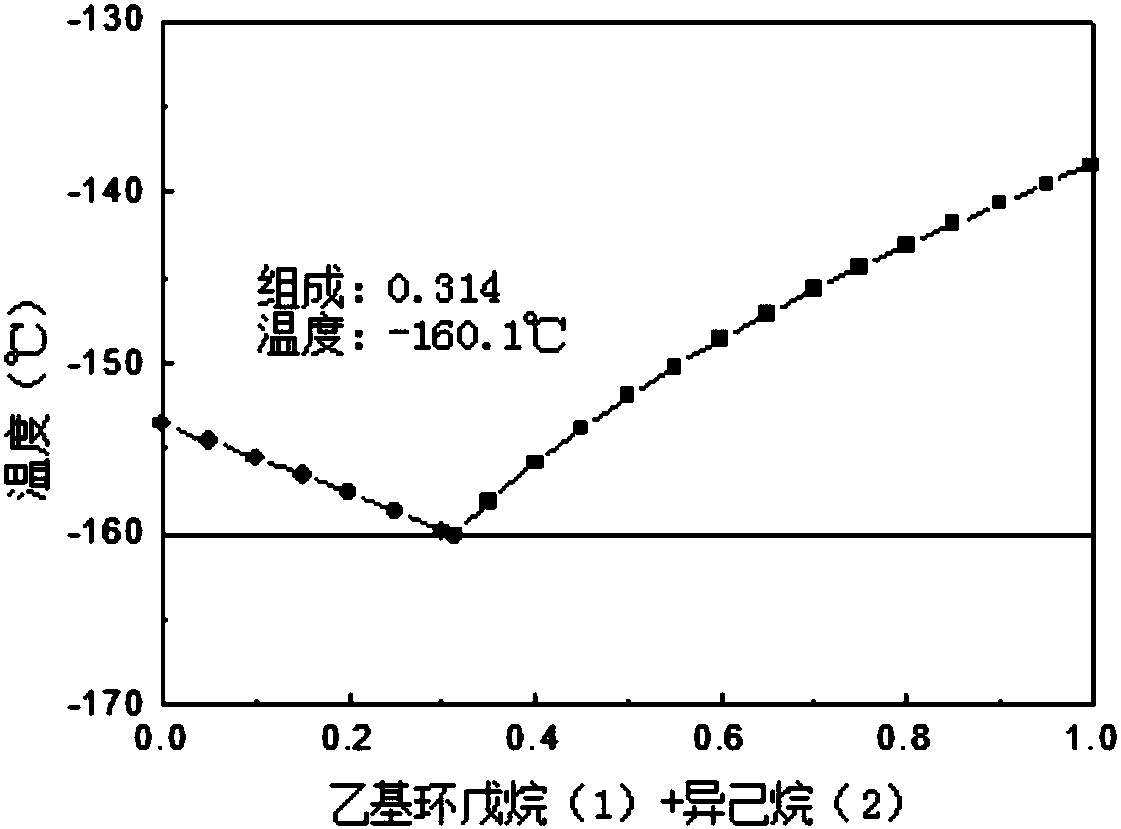

[0042] Embodiment 1 is applicable to a kind of liquid medium of -140 ℃

[0043] see figure 1 , is a schematic diagram of realizing the eutectic temperature of the low temperature medium provided in Example 1 of the present invention. In this embodiment, the cryogenic medium adopts a binary mixture in an alkane composition, mixing ethylcyclopentane and isohexane in a certain proportion, when the proportion of ethylcyclopentane does not exceed 50% (molar ratio) , the mixture of the two can achieve a solid-liquid phase transition temperature lower than their respective triple points, so it can be used as a liquid medium in a lower temperature region, especially when the molar ratio of ethylcyclopentane to isohexane is 0.314:0.686 Optimum, the eutectic temperature of the lowest temperature -160.1°C can be realized, and at this optimal ratio, the liquid medium requirement of -140°C can be met.

Embodiment 2

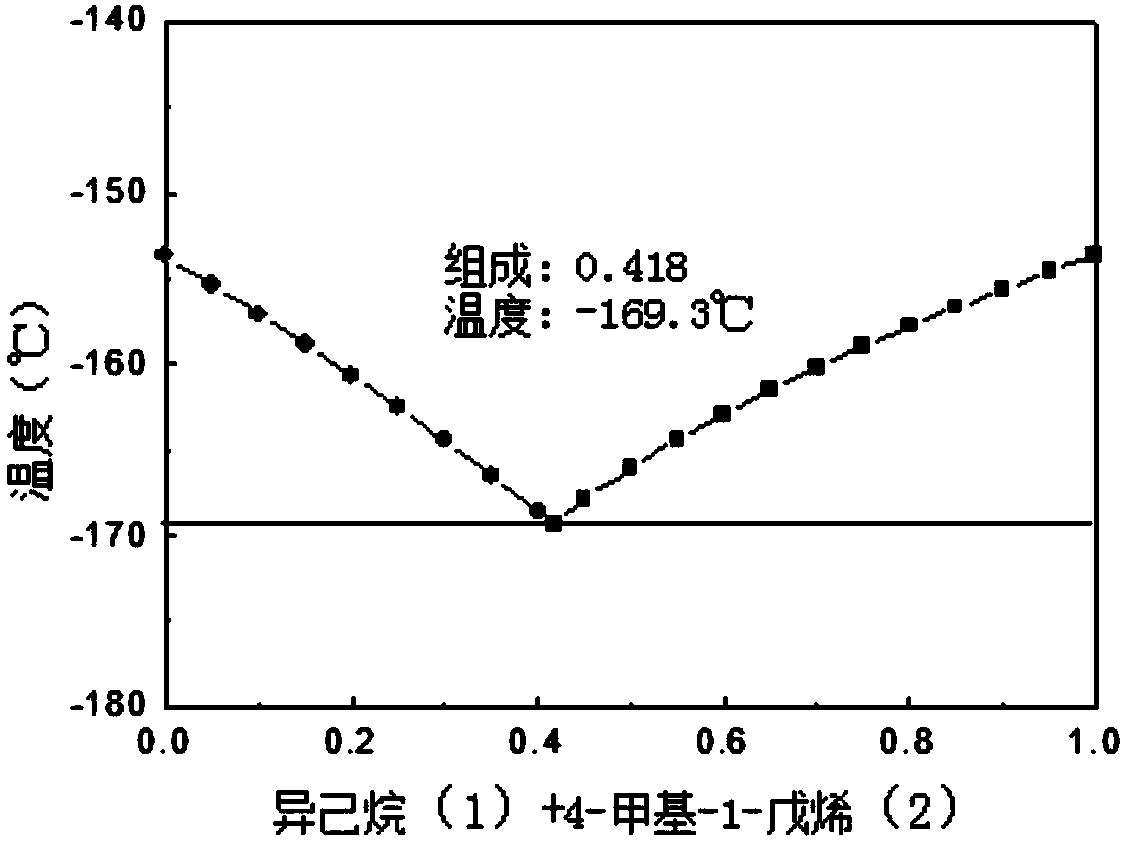

[0044] Embodiment 2 is applicable to a kind of liquid medium of -150 ℃

[0045] see figure 2 , is a schematic diagram of realizing the eutectic temperature of the low temperature medium provided in Example 2 of the present invention. , in this embodiment, the cryogenic medium uses a binary mixture of an alkane composition and an olefin composition, and isohexane and 4-methyl-1-pentene are mixed in a certain proportion, almost in any proportion, the two The mixture can realize the solid-liquid phase transition temperature lower than their respective triple points, so it can be used as a liquid medium in a lower temperature region, especially when the molar ratio of isohexane to 4-methyl-1-pentene is 0.418:0.582 It is optimal at the time, and the eutectic temperature with the lowest temperature of -169.3°C can be achieved. Under this optimal ratio, it can meet the requirements of liquid medium at -150°C.

Embodiment 3

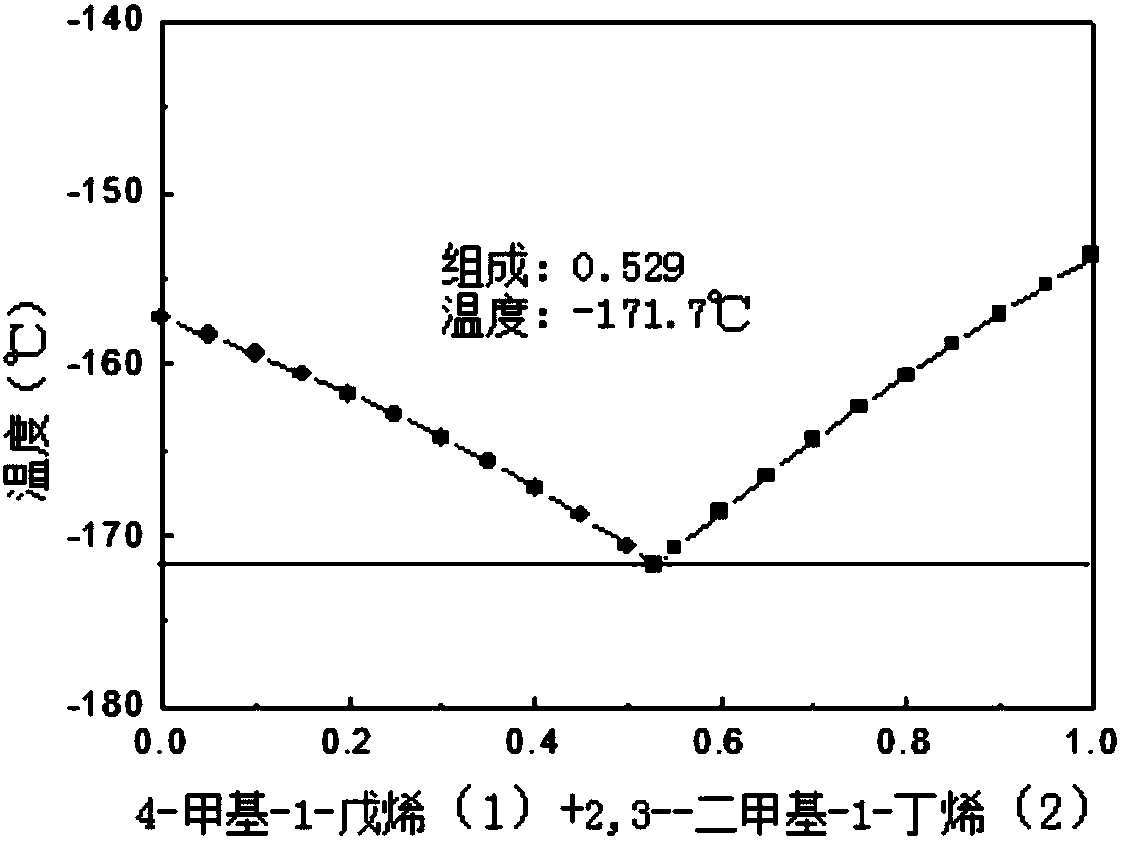

[0046] Embodiment 3 is applicable to a kind of liquid medium of -150 ℃

[0047] see image 3 , is a schematic diagram of realizing the eutectic temperature of the low temperature medium provided in Example 3 of the present invention. In this example, the low-temperature medium uses a binary mixture of olefinic compositions, mixing 4-methyl-1-pentene and 2,3-dimethyl-1-butene in a certain proportion, almost at any ratio, the mixture of the two can achieve a solid-liquid phase transition temperature lower than their respective triple points, so it can be used as a liquid medium in a lower temperature region, especially, between 4-methyl-1-pentene and 2,3 - The optimum molar ratio of dimethyl-1-butene is 0.529:0.471, which can achieve the lowest eutectic temperature of -171.7°C. Under this optimal ratio, it can meet the requirements of liquid medium at -150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com