Environment-friendly glutinous-rice gum for sheet production and preparation method of gum

A technology for sheet production and glutinous rice glue, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of being susceptible to bacteria, mildew, corrosion, etc., and achieve the effect of improving lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

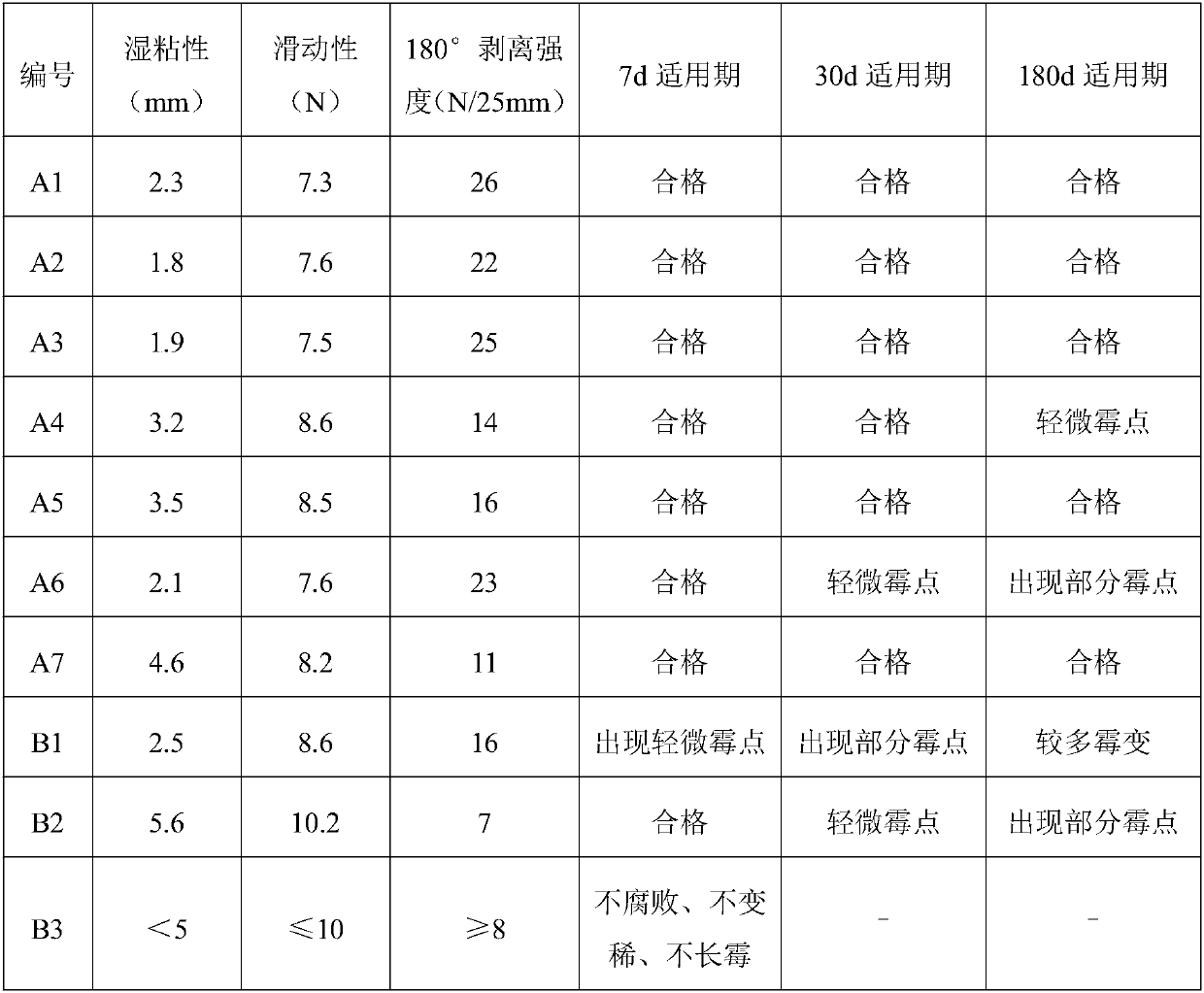

Examples

preparation example Construction

[0018] The invention provides a kind of preparation method of environment-friendly glutinous rice glue for plate production, wherein, comprise the following steps:

[0019] 1) Mix modifier, glacial acetic acid and absolute ethanol to prepare mixed solution M1;

[0020] 2) Under the condition of pH 3-5, add n-tetrabutyl titanate dropwise to the mixed solution M1 prepared above, and mix at a temperature of 60-100°C for 1-2 hours to obtain colloid M2 ;

[0021] 3) mixing glutinous rice flour, colloid M2, didecyldimethylammonium chloride, carrageenan, xanthan gum, locust bean gum, sodium carboxymethylcellulose and water to prepare environmentally friendly glutinous rice glue for board production; ,

[0022] The modifier is selected from at least one of pentaerythritol, propylene glycol, octapentyl glycol and stearic acid.

[0023] The present invention has the following beneficial effects: the present invention selects at least one of pentaerythritol, propylene glycol, octapent...

Embodiment 1

[0040] 1) Mix 0.5g of pentaerythritol, 5g of glacial acetic acid and 100g of absolute ethanol to prepare a mixed solution M1;

[0041] 2) Add concentrated hydrochloric acid to the above mixed solution M1 to adjust the pH to 3, add 3 g of n-tetrabutyl titanate dropwise to the above mixed solution M1 at a rate of 80 drops / min, and place in a water bath at a temperature of 60°C Mixed for 1 hour under the condition to obtain colloid M2;

[0042] 3) Extract 100g modified glutinous rice flour, 3g colloid M2, 0.5g didecyldimethylammonium chloride, 10g carrageenan, 10g xanthan gum, 5g locust bean gum, 1g carboxymethylcellulose sodium, 30g mugwort leaves The mixture was mixed with 600g of water by ultrasonic vibration for 10min to obtain the environmentally friendly glutinous rice glue A1 for board production.

Embodiment 2

[0044] 1) Mix 2g of propylene glycol, 20g of glacial acetic acid and 100g of absolute ethanol to prepare a mixed liquid M1;

[0045] 2) Add concentrated hydrochloric acid to the above mixed solution M1 to adjust the pH to 5, add 10 g of n-tetrabutyl titanate dropwise to the above prepared mixed solution M1 at a rate of 200 drops / min, and place in a water bath at a temperature of 100°C Mixed for 2 hours under the same conditions to obtain colloid M2;

[0046] 3) 100g modified glutinous rice flour, 10g colloid M2, 2g didecyldimethylammonium chloride, 20g carrageenan, 20g xanthan gum, 15g locust bean gum, 5g sodium carboxymethylcellulose, 20g camphor extract Mix with 1000g of water for 15 minutes by ultrasonic vibration to obtain the environmentally friendly glutinous rice glue A2 for board production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com