Titanium dioxide silicon-aluminum coating method

A technology of titanium dioxide and silica-alumina, which is applied in the direction of chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of insufficient brightness of titanium dioxide, difficulty in washing, and large amount of washing water, etc., and achieve a dense coating film and reduce The effect of washing water volume and production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

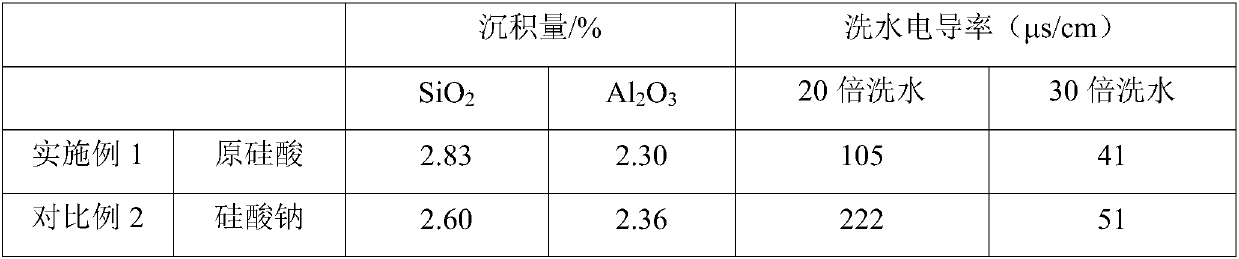

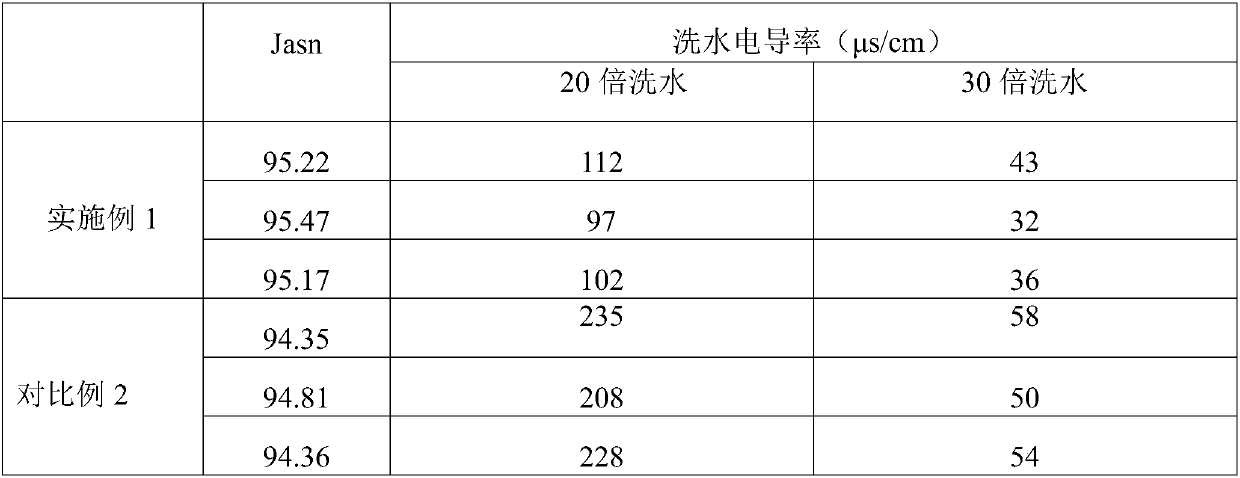

[0033] Embodiment 1 uses the inventive method to carry out coating to titanium dioxide

[0034] Take 300g of the primary product of titanium dioxide and add it to 1000ml of deionized water (300g / L), stir at a high speed for beating, heat to 90°C, adjust the pH to 10 with sodium hydroxide, and add 100g / L dropwise with two peristaltic pumps under stirring conditions Orthosilicic acid solution (as SiO 2 ) and 10% sodium hydroxide to keep the pH value of the slurry between 7.5 and 8.0, the total amount of silicon added dropwise is 3% of the weight of untreated titanium dioxide, and the dropwise addition is completed within 90 minutes. After the dropwise addition, mature for 120 minutes . Add the sodium metaaluminate of 100g / L and the sulfuric acid of 10% concurrently, the amount that adds sodium metaaluminate is 2% (as Al 2 o 3 During this process, the pH was maintained at 6.0-8.0, and the addition was completed within 90 minutes, matured for 60 minutes, adjusted to pH 7.0, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com