Vegetable protein foaming agent and preparing method thereof

A plant protein and foaming agent technology, applied in the field of foaming agent, can solve the problems of high foam connectivity, high bubble opening rate, poor foam stability, etc., to achieve low water content of bubbles, good flexibility of bubbles, stable foam The effect of ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

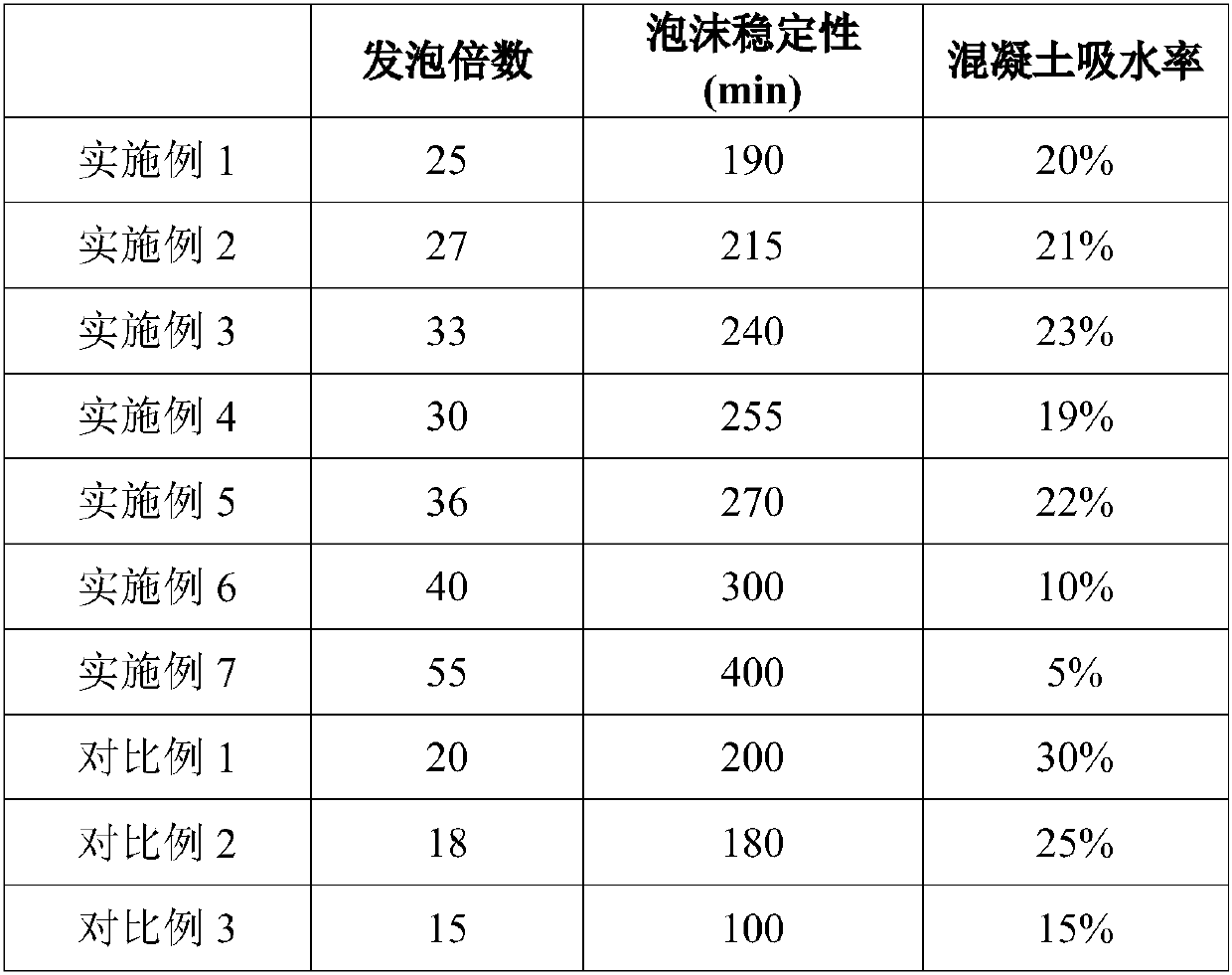

Examples

preparation example Construction

[0065] As a preferred technical solution of the present invention, the preparation method of the modified cellulose at least includes the following steps:

[0066] a. Take long-chain alkyl acid chloride and cellulose according to the molar ratio of COCl / OH of 0.1-5, choose long-chain aliphatic hydrocarbon as solvent, the quality of solvent is 5-100 times of cellulose, put the above raw materials into a container ;

[0067] b. The reaction temperature of the control system is 50-200°C, and the reaction time is 3-24 hours;

[0068] c. After the reaction is finished, cool down and pour the upper layer solution into a recovery bottle, put the bottom precipitate into an oven for drying, the drying temperature is 30-120°C, and the drying time is 3-15 hours, and the modified cellulose is obtained;

[0069] The long-chain alkyl acid chloride is a branched or straight-chain alkyl acid chloride with 10-18 carbon atoms; the long-chain aliphatic hydrocarbon is a straight-chain or branche...

Embodiment 1

[0106] Embodiment 1 provides a kind of vegetable protein foaming agent, by weight, at least includes the following components:

[0107] Vegetable protein: 1 part by weight,

[0108] Stabilizer: 0.1 parts by weight,

[0109] Dispersant: 0.1 parts by weight,

[0110] Water: 98.8 parts by weight;

[0111] The vegetable protein is a mixture of saponin vegetable protein and tea saponin vegetable protein with a weight ratio of 3:1; the dispersant is sodium dodecylbenzenesulfonate; and the stabilizer is gum arabic.

[0112] The preparation method of vegetable protein foaming agent comprises the following steps:

[0113] a. Take 98.8 parts by weight of water and heat it to 35°C;

[0114] b. Add 1 part by weight of vegetable protein and stir for 15 minutes to make the vegetable protein disperse evenly;

[0115] c. Add 0.1 parts by weight of a stabilizer and 0.1 parts by weight of a dispersant, stir for 30 minutes to make it fully foam, and then obtain a vegetable protein foaming a...

Embodiment 2

[0118] Embodiment 2 provides a kind of plant protein foaming agent, by weight, at least comprises the following components:

[0119] Vegetable protein: 20 parts by weight,

[0120] Stabilizer: 1 part by weight,

[0121] Dispersant: 1 part by weight,

[0122] Water: 78 parts by weight;

[0123] The vegetable protein is a mixture of saponin vegetable protein and tea saponin vegetable protein with a weight ratio of 3:1; the dispersant is sodium dodecylbenzenesulfonate; and the stabilizer is gum arabic.

[0124] The preparation method of vegetable protein foaming agent comprises the following steps:

[0125] a. Take 78 parts by weight of water and heat it to 35°C;

[0126] b. Add 20 parts by weight of vegetable protein and stir for 15 minutes to make the vegetable protein disperse evenly;

[0127] c. Add 1 part by weight of a stabilizer and 1 part by weight of a dispersant, stir for 30 minutes to make it fully foam, and obtain a vegetable protein foaming agent.

[0128] Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com