A kind of silicon-rich magnesia nickel slag sulfate-resistant cement and preparation method thereof

A technology of anti-sulfate cement and ordinary Portland cement, applied in the direction of cement production, can solve the problems of volume expansion, loss of cement strength, etc., and achieve the effect of compact structure, less erosion, and improved hydration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

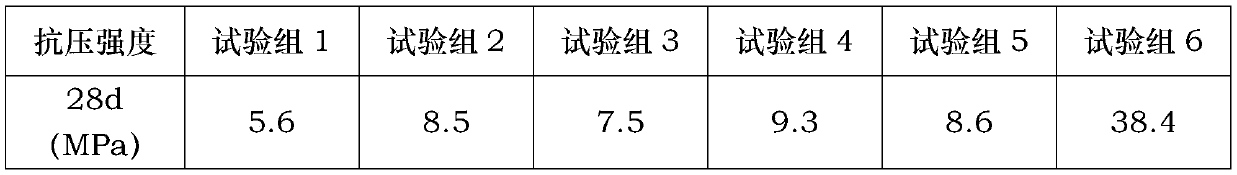

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

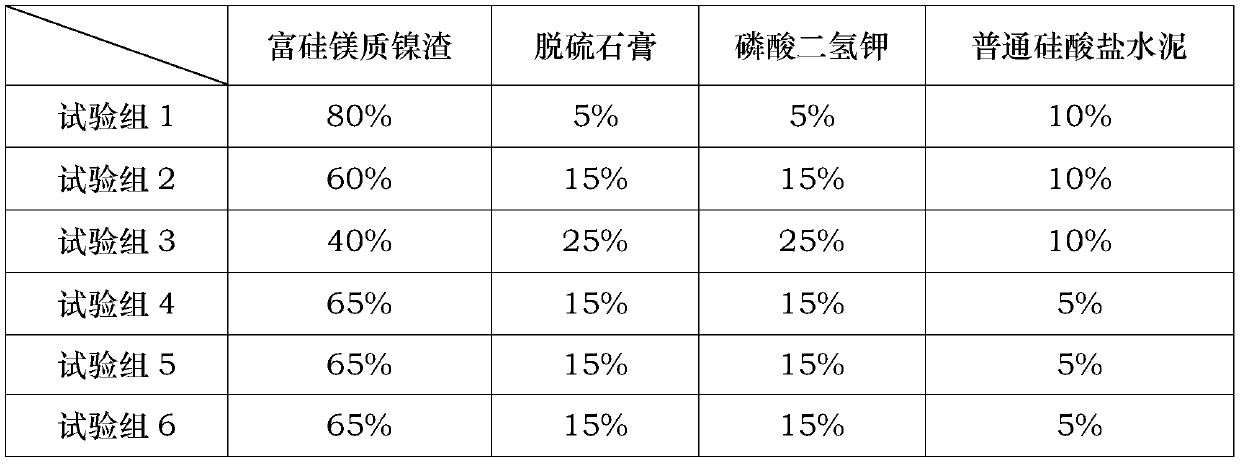

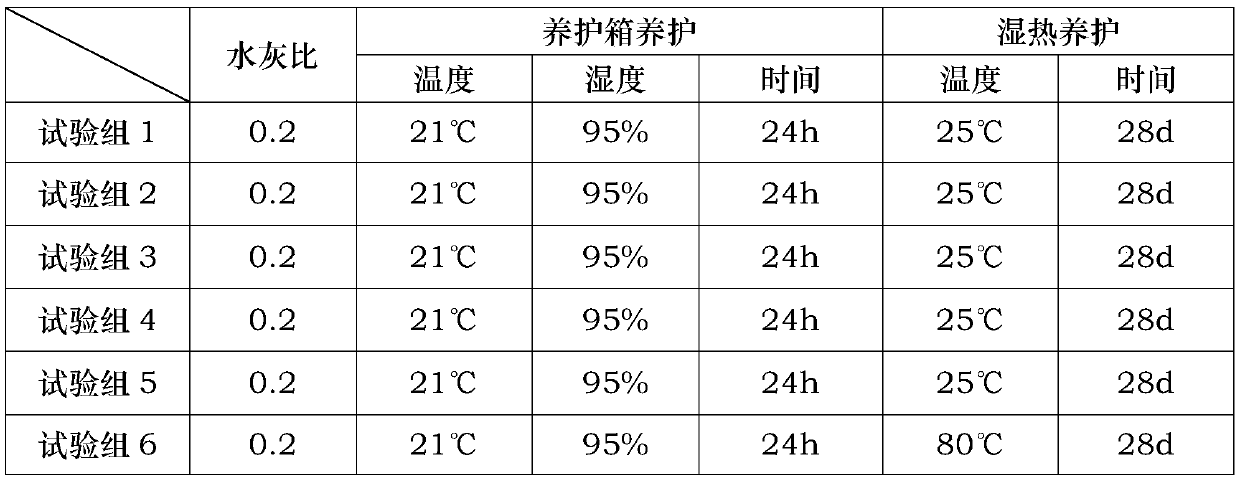

[0022] A kind of silicon-rich and magnesium-rich nickel slag-resistant sulfate cement of the present invention comprises the following components: ordinary Portland cement, silicon-rich and magnesium-rich nickel slag, desulfurization gypsum, potassium dihydrogen phosphate, and the ordinary Portland cement , silicon-rich magnesium-containing nickel slag, desulfurized gypsum, and potassium dihydrogen phosphate are respectively 5-10%, 60-80%, 10-20%, and 10-20% by mass.

[0023] A method for preparing silicon-rich magnesium nickel slag-resistant sulfate cement, specifically comprising the following steps:

[0024] Step 1, grinding silicon-rich and magnesium-rich nickel slag with a mass percentage of 60-80% until it passes through a 0.08mm square hole sieve, leaving about 30% of the sieve to make fine nickel slag powder;

[0025] Step 2, the desulfurization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com