Novel production line and production process for borosilicate glass

A borosilicate glass and production process technology, applied in glass production, glass molding, glass manufacturing equipment and other directions, can solve the problems of high labor intensity, low production efficiency, low labor efficiency, etc., and reduce labor occupation and efficiency. The effect of improving and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

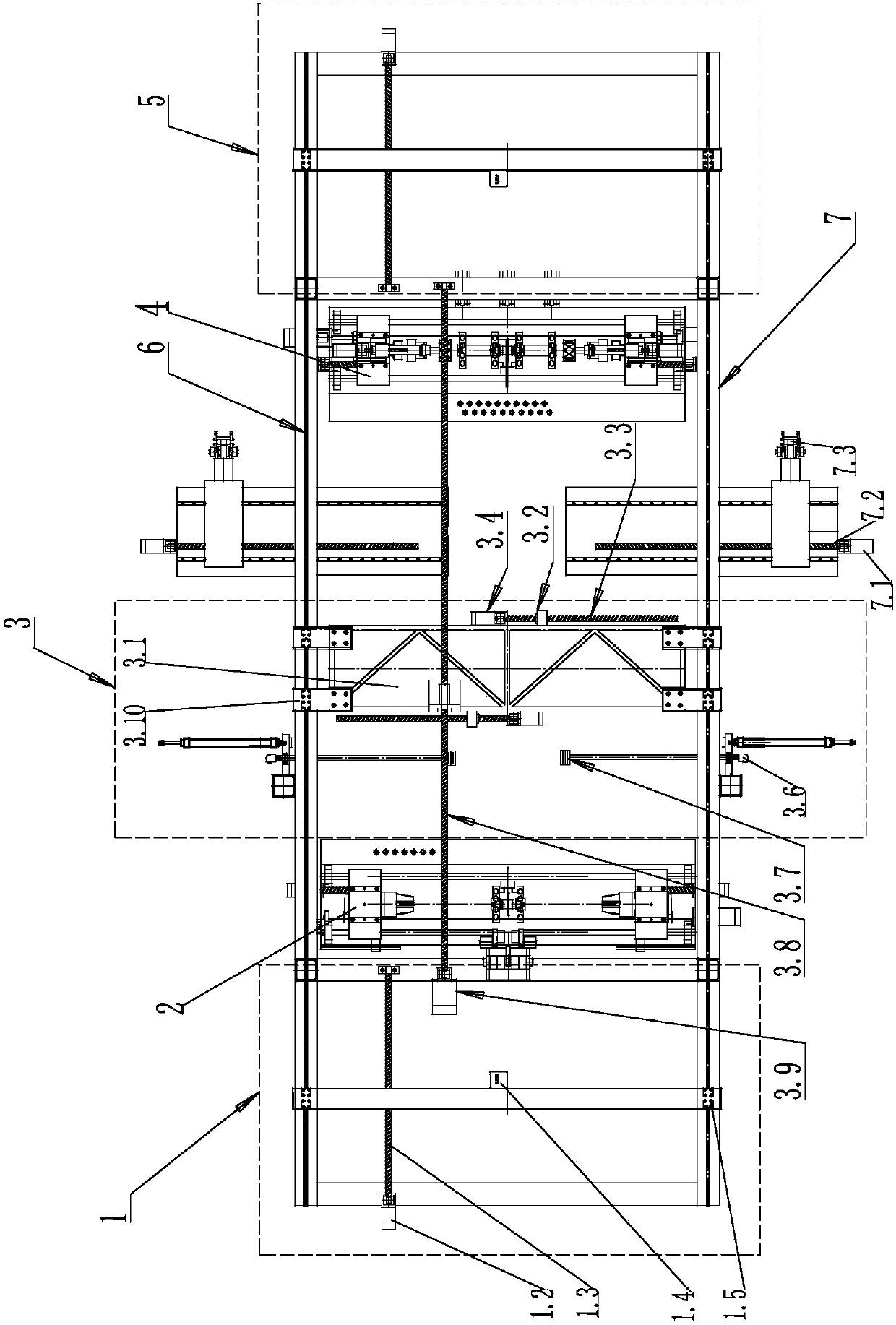

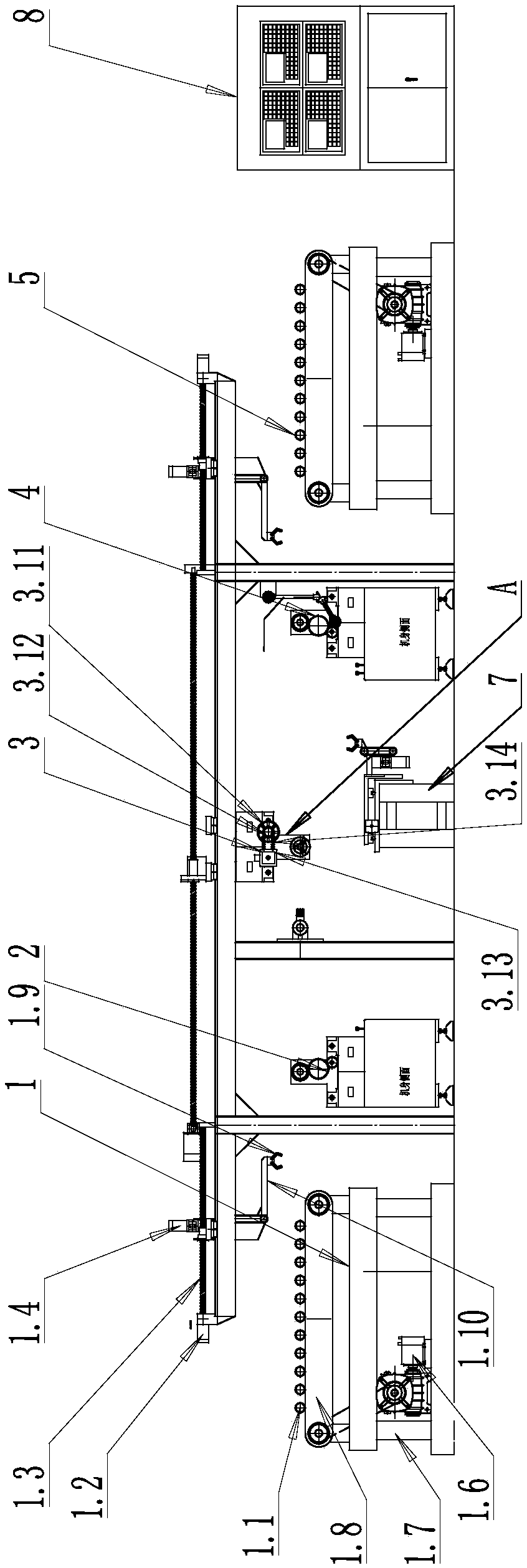

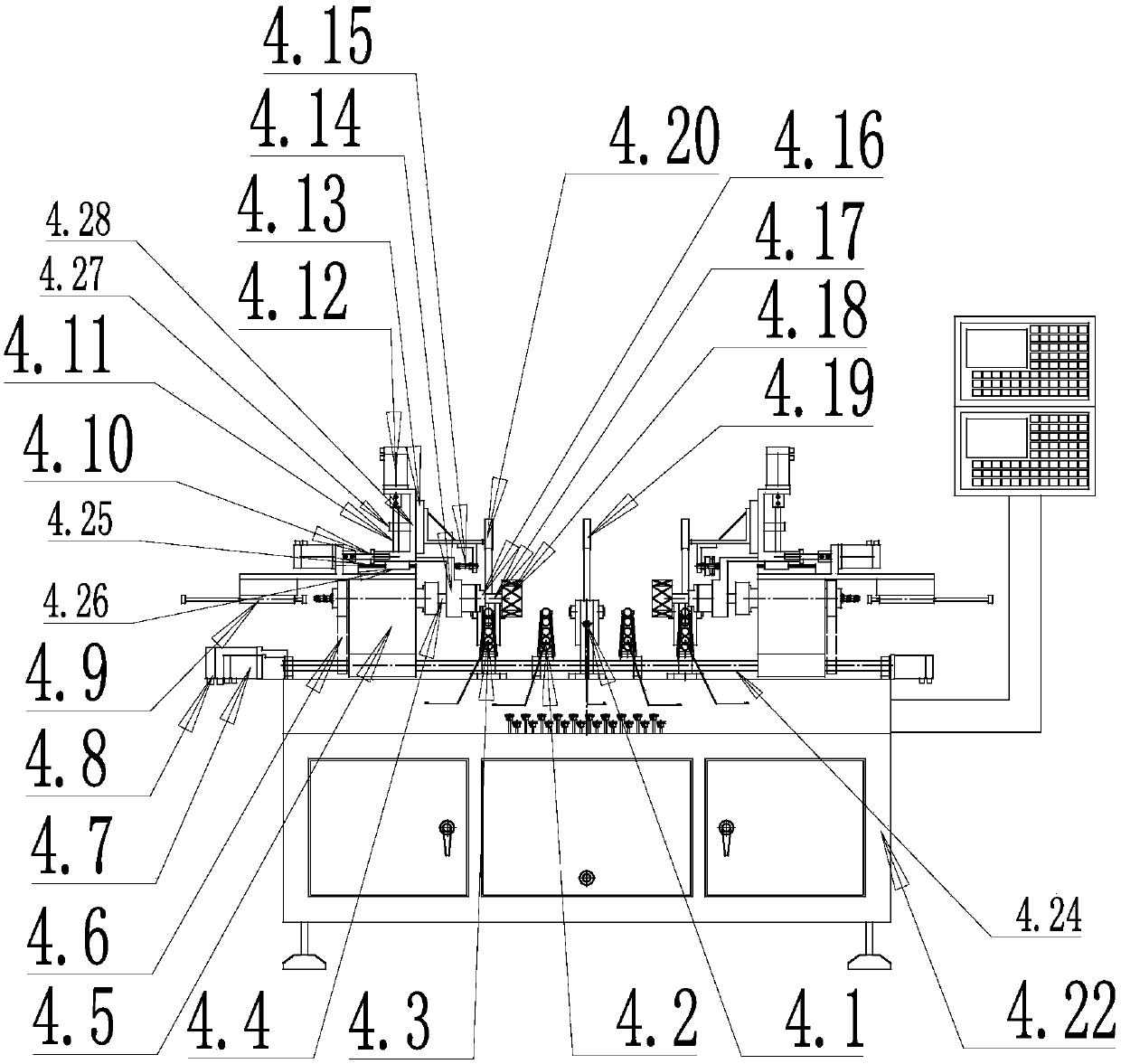

[0077] Such as Figure 1 to Figure 6 As shown, the novel borosilicate glass production line of the present invention includes a slide rail 6, a cleaning device 3 is arranged on the slide rail 6, and a bottom cutting device 2 and a bottom cutting, pressure, diameter and sealing integrated device 4 are arranged side by side under the slide rail 6. The bottom-cutting device 2 and the bottom-cutting, diameter-pressing and sealing-integrated device 4 are respectively located on both sides of the cleaning device 3 .

[0078] The cleaning device 3 includes a mobile clamping assembly, the mobile clamping assembly is arranged on the slide rail 6, and the bottom of the slide rail 6 is provided with a first cleaning fire head 3.7; the mobile clamping assembly 3.2 includes a mobile frame 3.1, and the mobile frame 3.1 is provided with a sliding The sliding block 3.10 that the rail 6 cooperates, the bottom of the mobile frame 3.1 is provided with a clamping assembly. The moving frame 3.1 c...

Embodiment 2

[0080] Such as Figure 1 to Figure 6 As shown, the clamping component is an external clamping component; the first cleaning fire head 3.7 is a built-in first cleaning fire head, and the built-in first cleaning fire head is a ring-shaped built-in first cleaning fire head, and the nozzles of the built-in first cleaning fire head are arranged radially; The built-in first cleaning fire head communicates with the air guide rod 3.6; the outer clamping assembly is connected with the first rotary drive device. The outer clamping assembly includes a support seat 3.22, and an automatic gripper 3.23 is arranged on the support seat 3.22, and the automatic gripper 3.23 is connected to the first rotary drive device through a chain 3.21. The automatic jaw 3.23 can be a pneumatic jaw; the pneumatic jaw is a prior art, simple in structure, and firmly clamped. The clamping assembly 3.2 and the first cleaning torch 3.7 can be arranged in multiple groups, and two groups of the clamping assembly ...

Embodiment 3

[0082] Such as Figure 1 to Figure 6 As shown, the first rotary driving device is a first rotary motor 3.13, and the first rotary motor 3.13 is connected to the coaxial gear 3.12 of the magnetic powder clutch 3.11 through a synchronous transmission chain 3.14. All the other are with embodiment two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com