A clamping and processing method for multi-station inner wing parts

A multi-station and parts technology, applied in the direction of metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of frequent clamping and replacement, consume huge manpower and material resources, and restrict the development of missile weapon manufacturing industry, etc., and achieve reduction The effect of production preparation time and artificial delay time, concentrated and continuous processing time, and shortened machine downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] The present invention proposes a processing method for processing multi-type inner wing parts, which specifically includes the following steps:

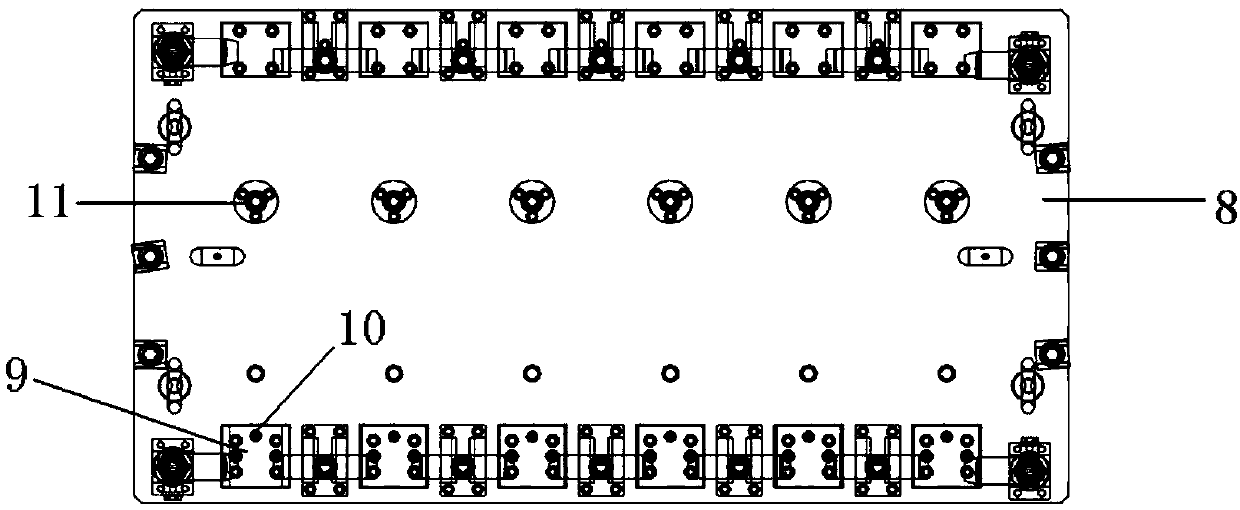

[0033] Step 1. First design three multi-station clamping fixtures for the processing of multi-model inner wing parts: 1. Rough machining fixture; 2. Finishing deep cavity fixture; 3. Finishing both side profile fixtures.

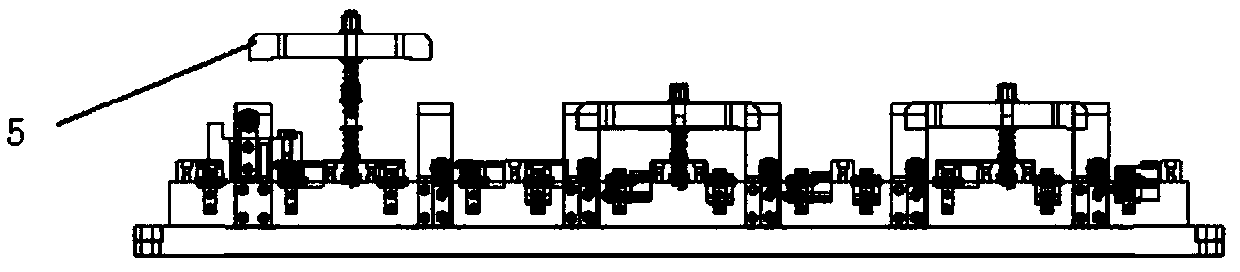

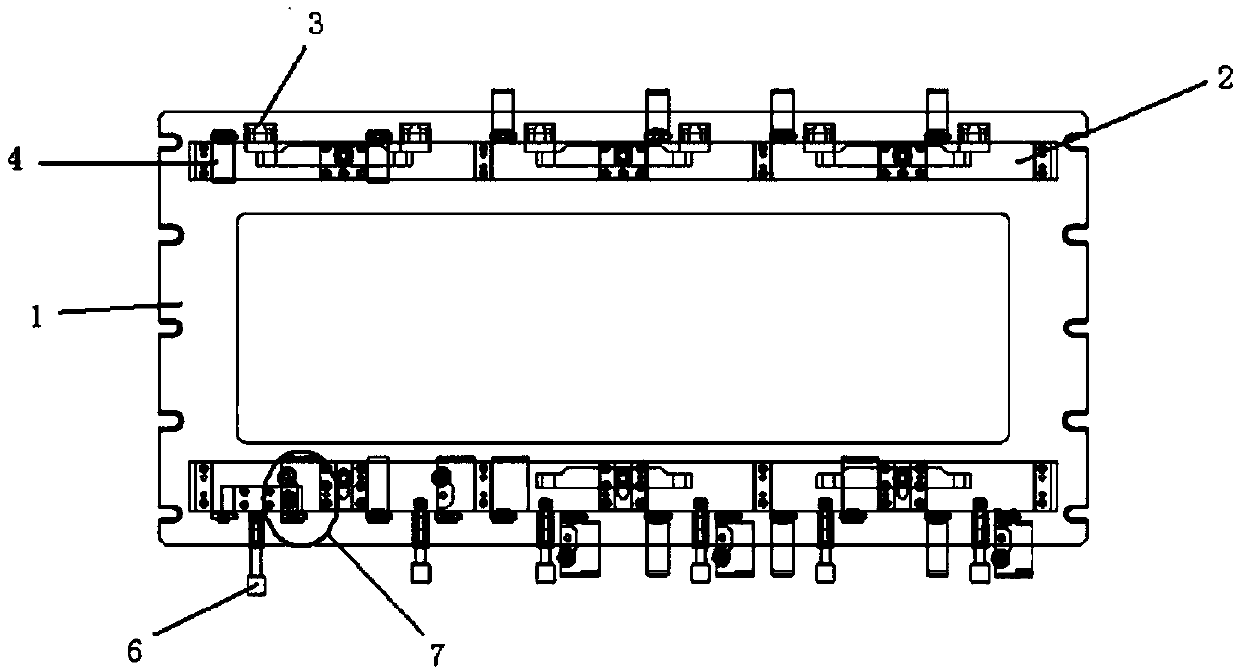

[0034] The rough machining fixture structure includes: a first base 1, a first positioning unit 2, a second positioning unit 3, a third positioning unit 4, a first pressing unit 5, a second pressing unit 6, and a third pressing unit 7 , the size of the first base 1 is determined according to the size of the XH-718 worktable of the machine tool used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com