Alkali free aluminate sulfate based shotcrete accelerator as stable suspension or redispersible solid

A technology of accelerator and concrete, applied in aluminum sulfate, aluminum sulfur compound and other directions, can solve the problems of complex and unstable system, and achieve the effect of long shelf life, prolong shelf life and reduce transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1 (precipitated by concentration)

[0080] In a closed reactor, at 80°C, aluminum sulfate hydrate (Al 2 (SO 4 ) 3 14H 2 O) and aluminum hydroxide powder were mixed with 4 parts by weight of water in a weight ratio of 8:1. After a few minutes, the solution turned pale yellow, indicating that all starting material had dissolved and the reaction had started. The reactor was then opened to allow the water to evaporate. When 3 to 3.5 parts by weight of water evaporated, the reactor was closed and the temperature was set to 60°C. After some time (about 1 to 3 hours), the mixture thickened due to the growth of crystals in solution. The mixture was then rapidly cooled to room temperature and became solid within 5-10 minutes. Figure 5 are photographs of the obtained solid being broken into lumps and finally ground into powder, respectively.

[0081] The main phase of the solid formed is

[0082] 1.Al(SO 4 )OH·5H 2 O (oblique aluminum alum)

[0083] 2.Al 2...

Embodiment 2

[0086] Example 2 (direct precipitation by stoichiometric method)

[0087] Aluminum sulfate hydrate (Al 2 (SO 4 ) 3 14H 2 O) and aluminum hydroxide are mixed with water (weight ratio 8:1:0.8). The solid melted after a few minutes. The mixture was maintained at 120°C while mixing for about 1 hour. When it started to thicken, the mixture was then drained from the reactor and cooled to room temperature. It became solid within minutes.

[0088] The main phase of the solid formed is

[0089] 1. (H 3 O)Al 3 (SO 4 ) 2 (OH) 6 (hydroalumite), more than 50%

[0090] 2.Al 2 (SO 4 ) 3 ·xH 2 O, where 14

[0091] 3.Al(SO 4 )OH·5H 2 O (clinolum), only traces

[0092] The solid can remain in solid form, or can be redispersed as a suspension in water.

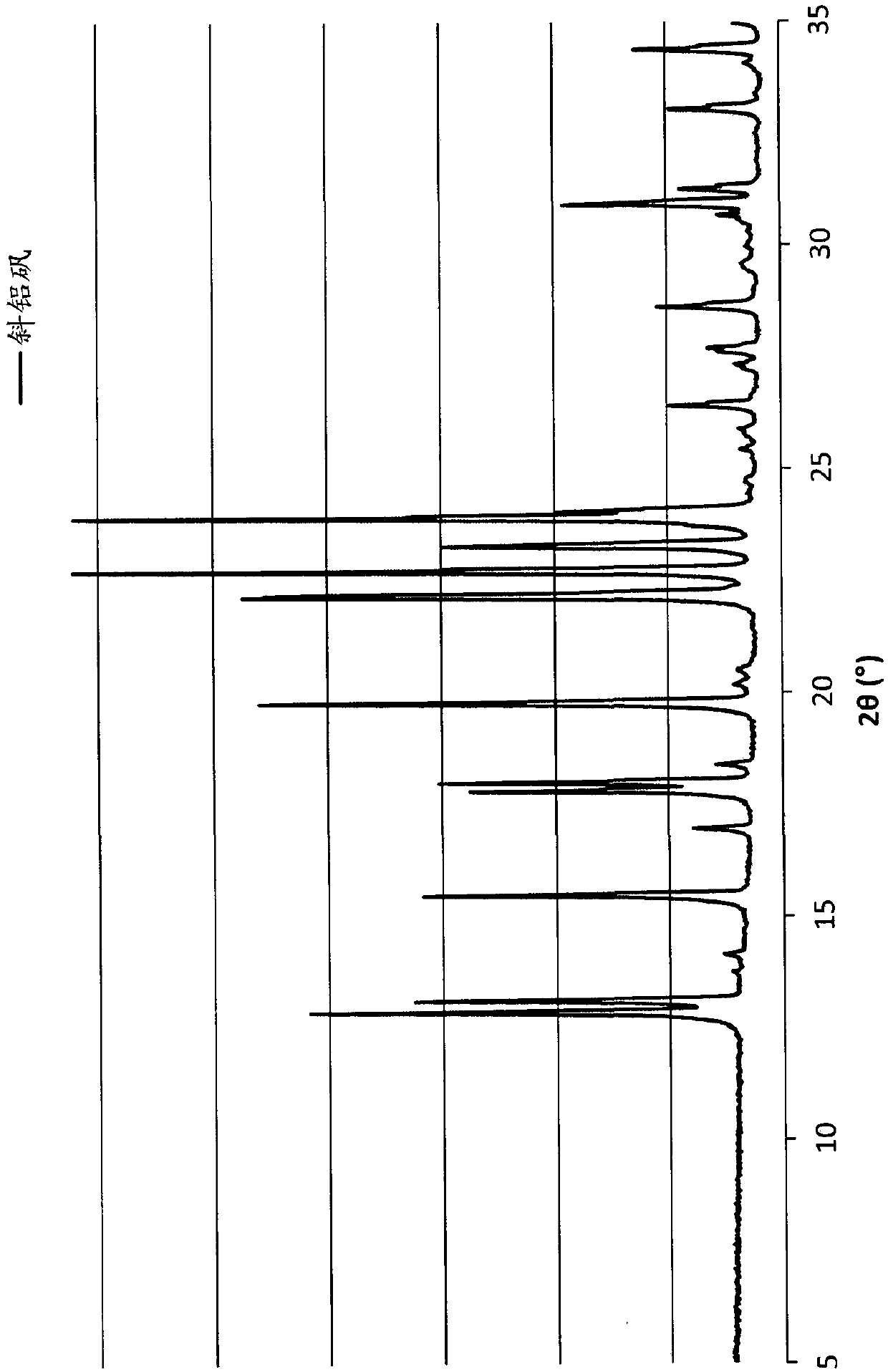

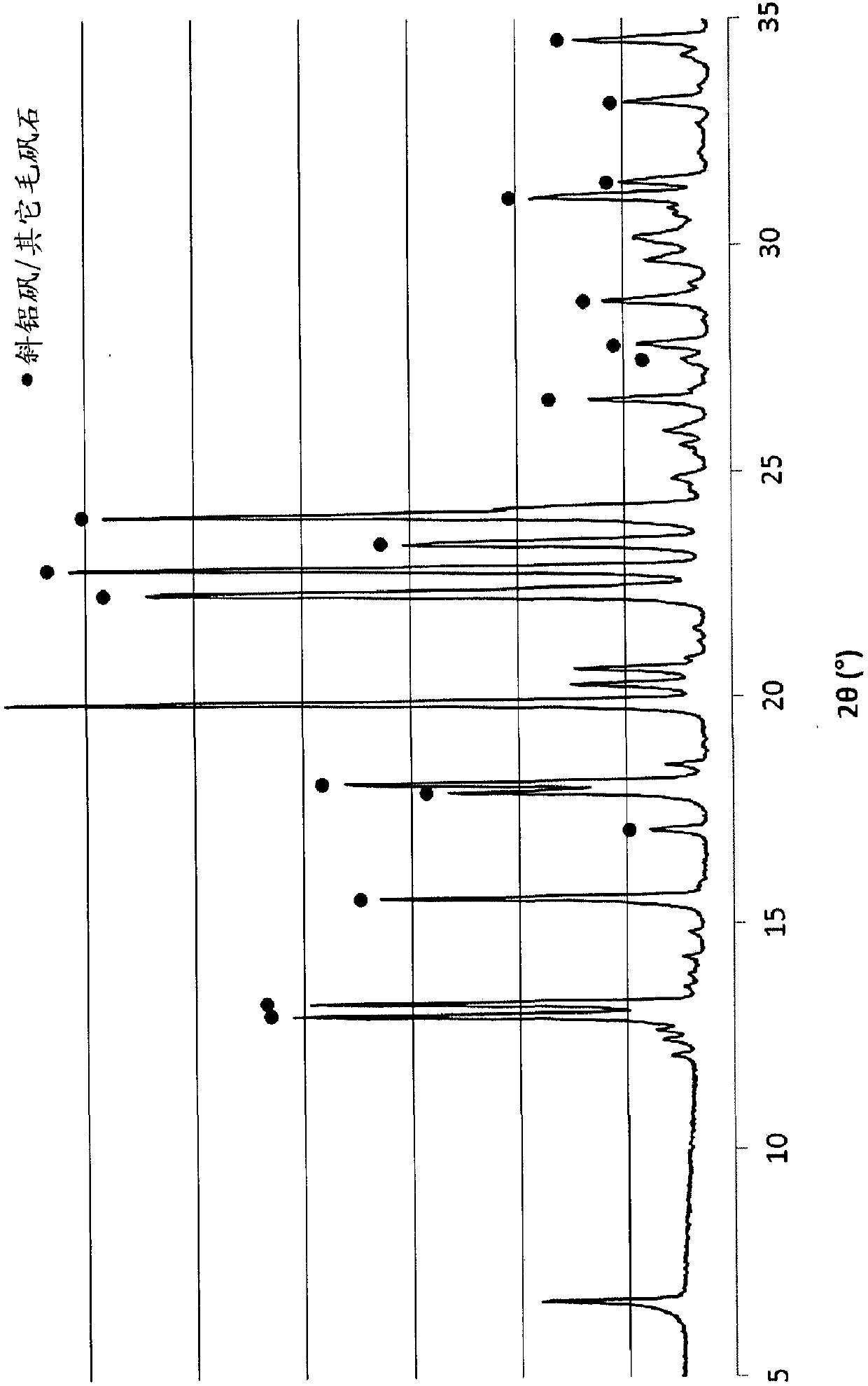

[0093] Analysis by X-ray Diffraction (XRD)

[0094] The solids prepared in Examples were analyzed by XRD, and the above-mentioned main phase was determined from XRD.

[0095] ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com