Spraying membrane heater for porous ceramic block

A technology of porous ceramics and heaters, used in electric heating devices, ohmic resistance heating, ohmic resistance heating components, etc., can solve the problem of large space occupation, achieve high heating efficiency, realize power changes, and increase the effect of area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

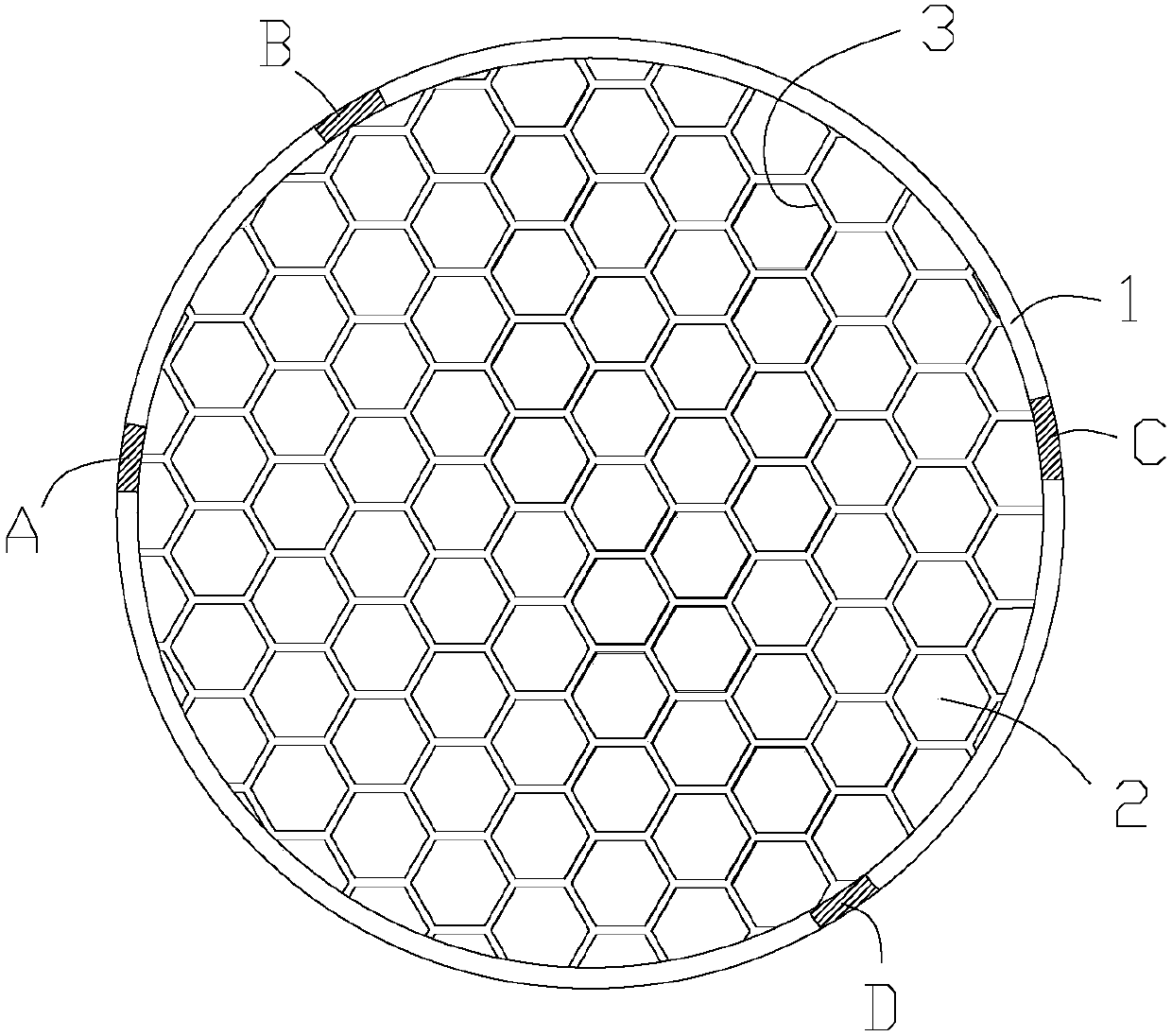

[0025] refer to figure 1 , The main body of the heater of the present invention is a ceramic base material 1, and the ceramic base material 1 preferably adopts ninety-five alumina porcelain. The ceramic base material 1 can be in a regular shape such as a square, a truncated cone, a sphere, or an irregular shape.

[0026] Perforations 2 are distributed on the ceramic substrate 1 . The setting method of the perforation 2 can be flexibly changed and set according to the required heating effect. Specifically, the distribution position and distribution number of the through holes 2 on the ceramic base material 1 , the shape and area size of the through holes 2 can be flexibly changed. For example, for the distribution position, the perforation 2 can be as attached figure 1 As shown in the embodiment of the present invention, it is distributed on the entire ceramic substrate 1, and may also be different from the structure of this embodiment, and is only distributed on a part or s...

Embodiment 2

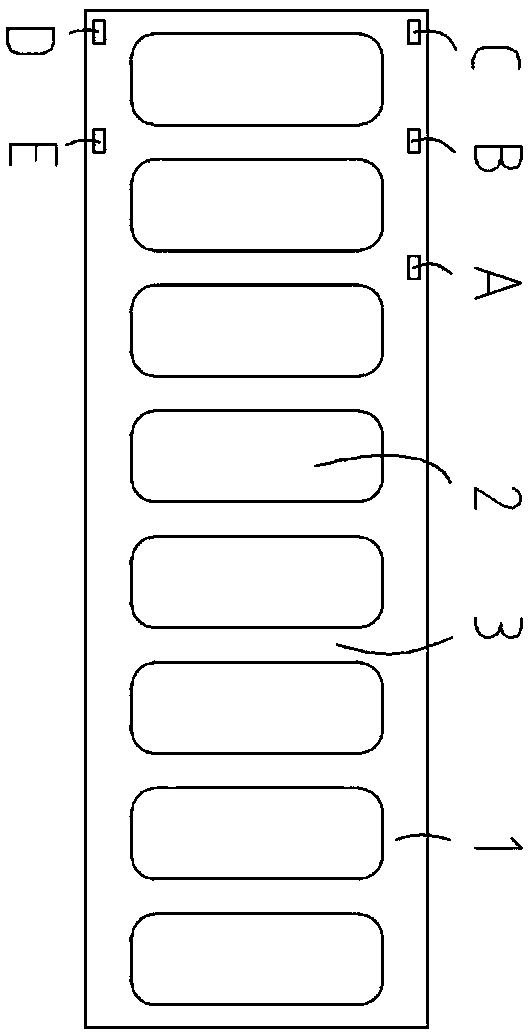

[0032] refer to figure 2 , The main body of the heater of the present invention is a ceramic base material 1, and the ceramic base material 1 preferably adopts ninety-five alumina porcelain. The ceramic substrate 1 is elongated, and the ceramic substrate 1 is distributed with perforations 2 . The perforations 2 are distributed on the entire ceramic substrate 1 . The perforations 2 are arranged at intervals, and the number of the perforations 2 is small; the perforations 2 are rectangular. This kind of structural setting can increase the specific surface area, and the ceramic base material 1 with a small volume can achieve the effect of high-power heating, and improve the space utilization rate; the injection mold in the hole is convenient.

[0033] The shape and area of perforation 2 are exactly the same.

[0034] A heating film 3 is spray-coated on part or all of the inner wall surfaces of part or all of the perforations 2 and part or all of the surface of the ceramic sub...

Embodiment 3

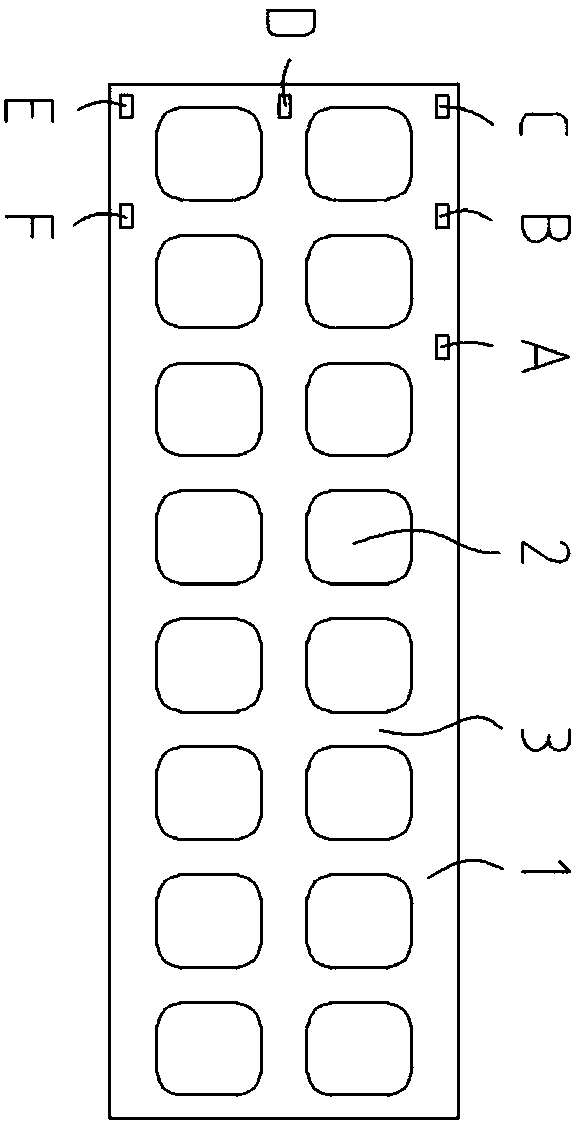

[0041] refer to image 3 , The main body of the heater of the present invention is a ceramic base material 1, and the ceramic base material 1 preferably adopts ninety-five alumina porcelain. The ceramic substrate 1 is elongated.

[0042] Perforations 2 are distributed on the ceramic substrate 1, and the perforations 2 are distributed on the entire ceramic substrate 1. The perforations 2 are arranged at intervals, and the number of the perforations 2 is small; the perforations 2 are square, and the shape and area of the perforations 2 are exactly the same.

[0043] A heating film 3 is spray-coated on part or all of the inner wall surfaces of part or all of the perforations 2 and part or all of the surface of the ceramic substrate 1 .

[0044] There are 6 electric electrodes 4, which are A, B, C, D, E and F respectively. The six power-connecting electrodes 4 are respectively connected to the heating film 3 , and the resistance between two power-connecting electrodes is affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com