Sample injector for in-pile irradiation sample

A sample injector and sample technology, which is applied in the field of sample injectors for irradiating samples into the pile, can solve the problems of high labor intensity, high vibration and noise hazards, and low degree of automation, and achieve good stability and safety, vibration and the effect of slight noise and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

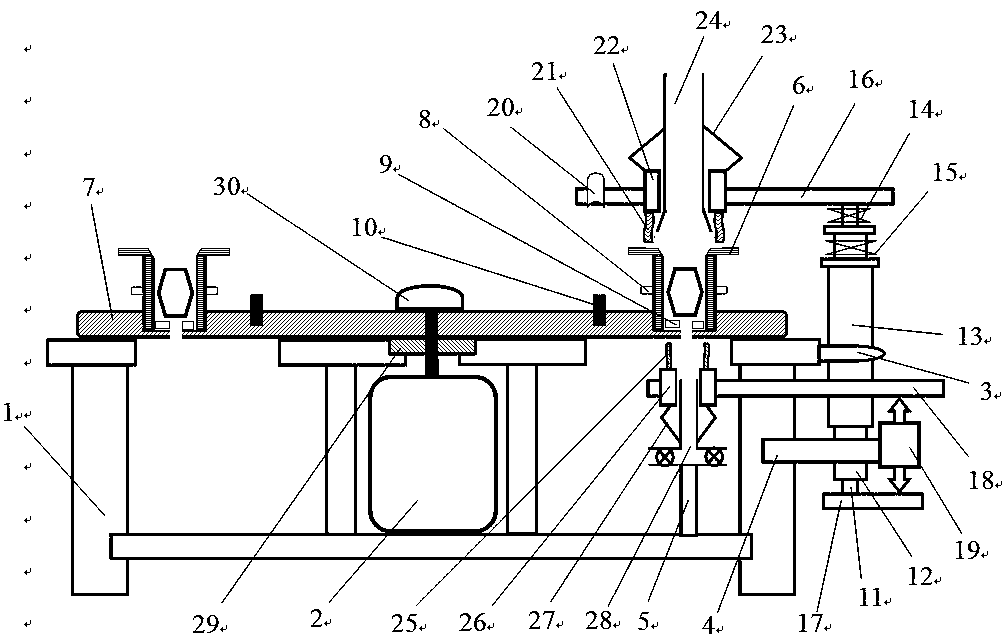

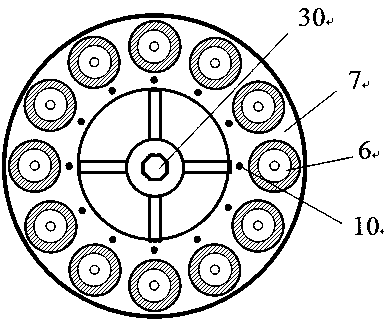

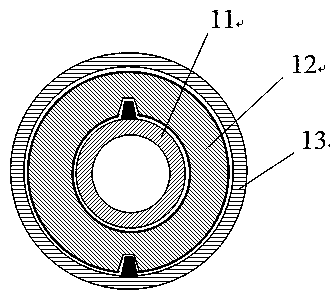

[0025] figure 1 It is a schematic diagram of the overall structure of a sample injector for stacking irradiation samples of the present invention, figure 2 It is a schematic diagram of the top view structure of the sample loading platform in the present invention, image 3 It is a schematic diagram of the cross-sectional structure of the sleeve of the sleeve mechanism in the present invention. exist Figure 1~Figure 3Among them, a sample injector for stacking irradiation samples of the present invention includes a bench 1, a motor 2, a sample loading platform 7, a sleeve mechanism, a sample transfer device, and a gas transfer device. The connection relationship is as follows: The motor 2 is fixedly installed in the platform 1, the sample loading platform 7 is installed horizontally on the platform 1, the sleeve mechanism is vertically installed on the side of the platform 1, and the sample transfer device and the gas transfer device are vertically arranged on the sample loa...

Embodiment 2

[0041] This embodiment is the same as Embodiment 1, except that fourteen sample loading chambers are arranged on the sample loading platform 7, and fourteen light sources are correspondingly arranged.

Embodiment 3

[0043] This embodiment is the same as Embodiment 1, except that sixteen sample loading chambers are arranged on the sample loading platform 7, and sixteen light sources are correspondingly arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com