Scale removal device for flue

A technology for flue and shaft installation, which is applied in the direction of removal of solid residue, treatment of combustion products, and combustion methods. Potential safety hazard, convenient operation, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

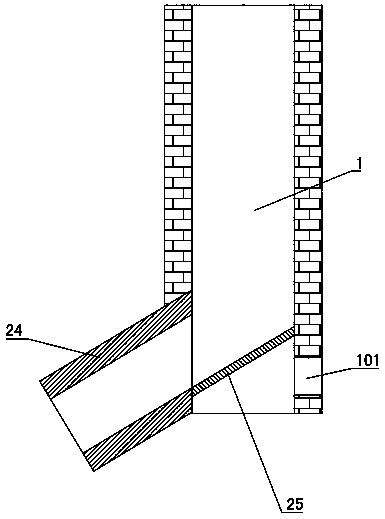

[0033] like figure 1 As shown: the bottom side of the flue 1 is provided with a smoke inlet 101, and the right side of the bottom of the flue 1 is provided with a liquid outlet pipe 24. The liquid outlet pipe 24 is inclined gradually rising from left to right, and the liquid outlet pipe The right end of 24 is aligned with the bottom of flue 1. The cleaning liquid is discharged out of the flue 1 through the liquid outlet pipe 24 . The liquid inlet end of the outlet pipe 24 is provided with a deflector 25, and the lower end of the deflector 25 is rotated and installed on the lower side of the outlet pipe 24. When the flue 1 needs to be cleaned, the upper end of the deflector 25 is turned to the right. Swing and stick to the inner wall on the right side of the flue 1, the cleaning liquid flows onto the deflector 25 and flows into the liquid outlet pipe 24 along the deflector 25, and closes the smoke inlet 101 of the flue 1, when the flue 1. During normal use, the upper side of ...

Embodiment 2

[0052] Such as Figure 8 As shown: the difference between embodiment 2 and embodiment 1 is that no installation box 6 and dry powder nozzle 11 are installed on the flue 1, and the middle part of the baffle plate 2 on the left is provided with a powder injection port, and the powder injection port is connected with a spray pipe 14 The high-pressure medium inlet of the injection pipe 14 is connected with compressed air, the low-pressure medium inlet of the injector 14 is arranged on the upper side of the injector 14, and is used to add fireproof powder, and the medium outlet of the injector 14 is connected to the powder injection port. A hopper 15 is provided on the upper side of the low-pressure medium inlet of the injector 14, and the hopper 15 has a tapered cross-sectional area gradually increasing from bottom to top, so that it is convenient to add fireproof powder. A feed valve 16 is provided between the hopper 15 and the low-pressure medium inlet of the injector 14 . Two ...

Embodiment 3

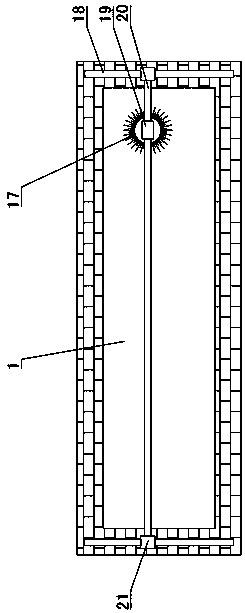

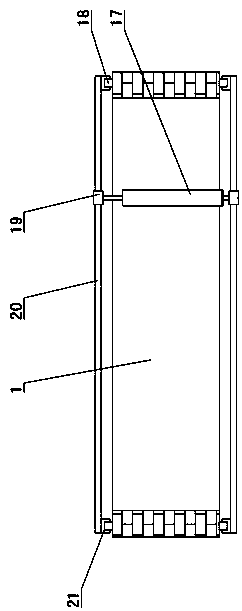

[0054] Such as Figure 9 Shown: the difference between embodiment 3 and embodiment 1 is: the diameter of the brush roller 17 is slightly larger than the width of the flue 1, and no adjustment mechanism is provided, and the two ends of the swing guide rail 20 are installed in the middle of the flue 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com