Completely-fused safety explosion-proof spring tyre

A tire and safety technology, applied in tire parts, tire tread/tread pattern, non-pneumatic tires, etc., can solve the problems of high cost, complicated principle and process, increase maintenance cost, etc., to achieve simple production and easy promotion , the effect of a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

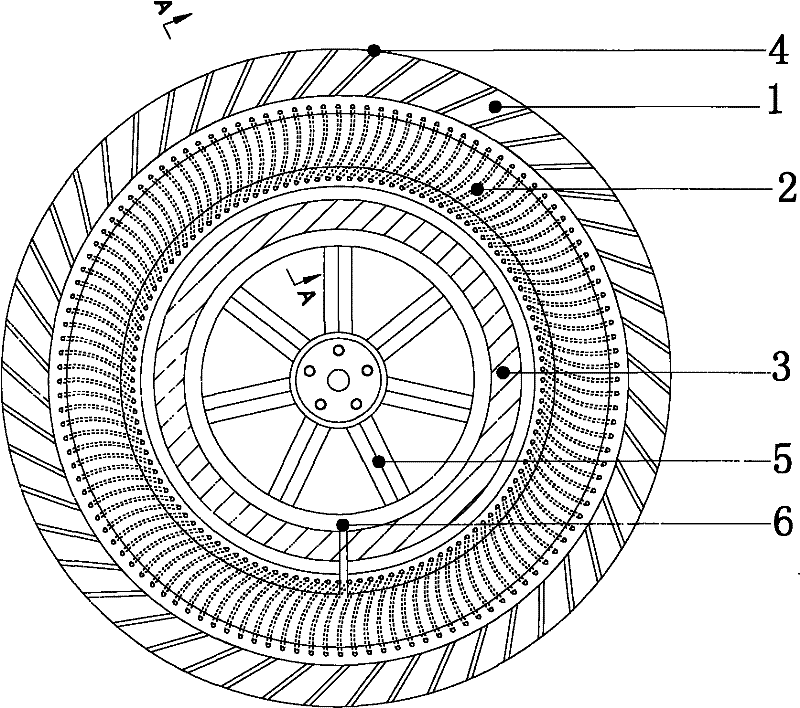

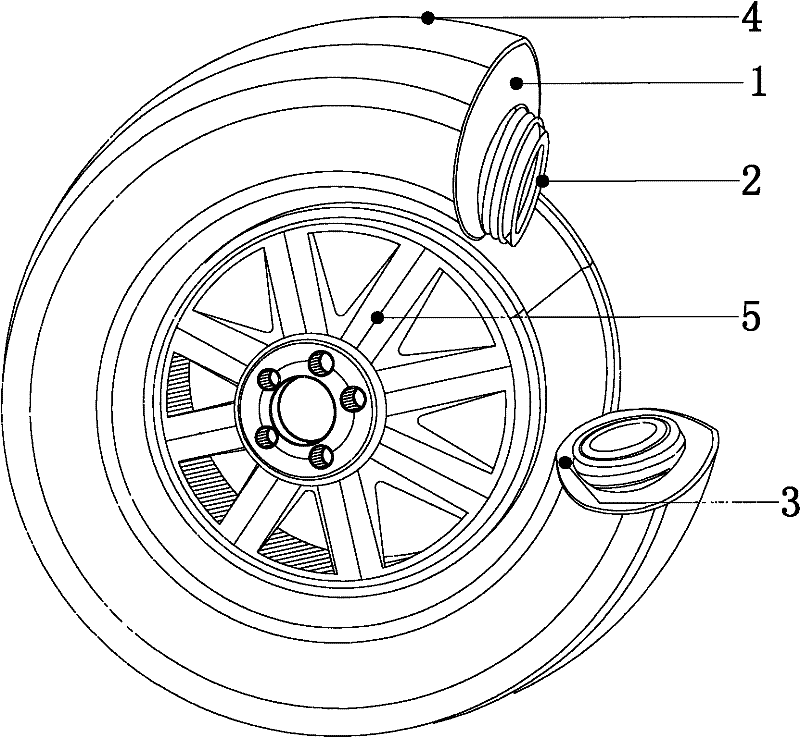

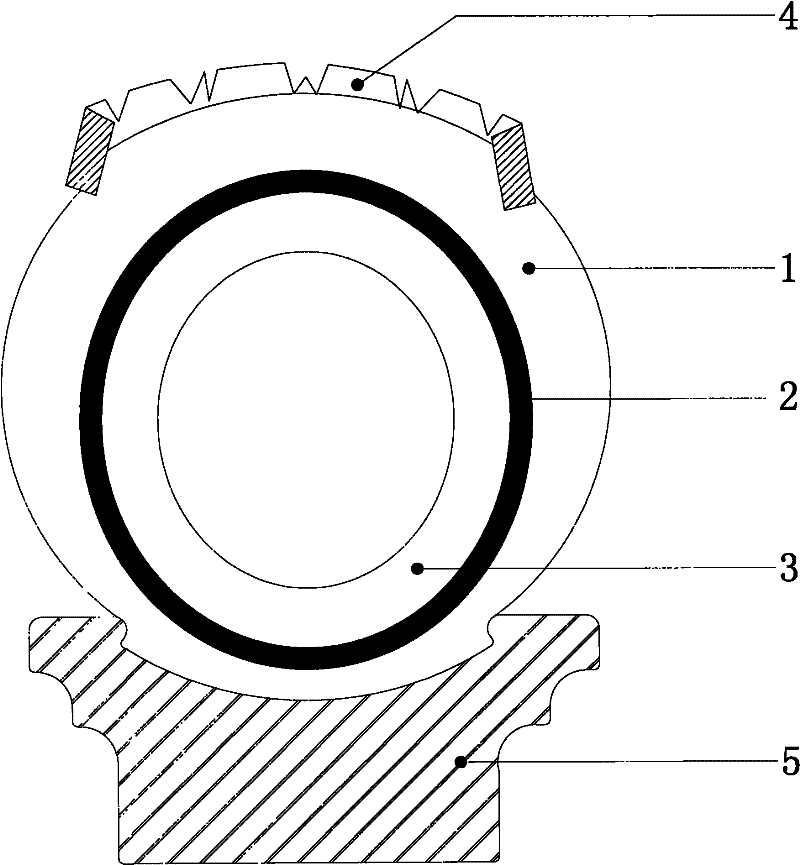

[0018] Such as figure 1 As shown, the present invention provides a fully integrated safety explosion-proof spring tire, including a rim, a ring-shaped carcass and a compression spring 2 arranged inside the carcass. The diameter of the arc in the carcass is larger than the maximum of the compression spring 2. The diameter portion becomes the outer carcass 1, and the portion smaller than the smallest diameter of the compression spring 2 becomes the inner carcass 3, and the thickness of the outer carcass 1 is greater than the inner carcass 3. The carcass and the compression spring 2 are tightly integrated. The outer surface of the carcass outer side 1 is provided with a carcass gear 4. The inner surface of the carcass inner side 3 of the carcass closely fits the outer contour of the rim 5.

[0019] The compression spring 2 required for the safety explosion-proof spring tire in this embodiment adopts a compression spring with high tissue stability, which is generally made of spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com