Preparation method of nano-modified fluorine-containing textile finishing agent

A fluorine-containing fabric, nano-modified technology, applied in fiber processing, textile and papermaking, liquid repellent fibers, etc., can solve problems such as increased residues and decreased monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

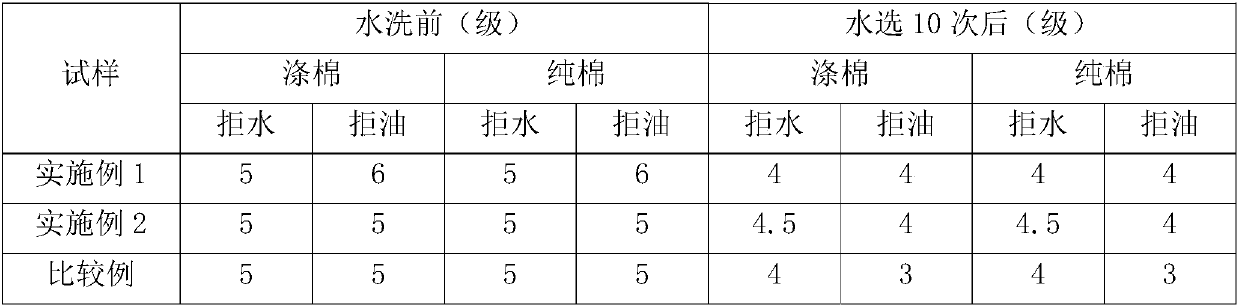

Examples

Embodiment 1

[0041] ⑴ Organic fluorine and epoxy modified nano-Si0 2 Water dispersion preparation (each raw material is by weight):

[0042] In a reactor equipped with a stirrer, a condenser, and a thermometer, add 100 parts of deionized water, 0.036 parts of sodium dodecylbenzenesulfonate, and 0.018 parts of perfluorinated mixed alkyl ethyl polyoxyethylene ether, stir to dissolve, Control the temperature at 20-40°C, add 3 parts of methyltrimethoxysilane while stirring, stir at high speed for 1.0-1.5 hours, add 2.5 parts of 25% ammonia water dropwise, and keep stirring for 3 hours; then add tetraethyl orthosilicate 2 part, stirred for 2 hours; then added 0.2 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, stirred for 20-30 minutes; added 0.01 part of perfluoroalkyl ethyl polyoxyethylene ether, drop Add 1.0 part of perfluorinated mixed alkyl ethyl trimethoxysilane, continue to stir for 4 hours, then add 0.02 part of perfluoro mixed alkyl ethyl polyoxyethylene ether, heat up and dehydra...

Embodiment 2

[0060] Organofluorine and epoxy-modified nano-SiO2 water dispersion liquid preparation (each raw material is by weight):

[0061] In Example 1, 0.2 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane were replaced by 0.3 parts, and 1.0 parts of perfluoro mixed alkyl ethyl trimethoxysilane were replaced by perfluorohexyl 1.0 parts of ethyl trimethoxysilane;

[0062] Preparation of acrylate copolymer emulsion modified by organic fluorine with low carbon chain content (each raw material is by weight):

[0063] In Example 1, 1.5 parts of acetoacetoxyethyl methacrylate in the shell monomer pre-emulsion 2 was replaced by 1.0 parts, and 1.5 parts of methacryloxypropyl triisopropoxysilane was replaced by vinyl 2.5 parts of triisopropoxysilane, 0.7 parts of adipic acid dihydrazide replaced with 0.53 parts;

[0064] The composition of other raw materials and the preparation process were the same as in Example 1 to obtain the nano-modified fluorine-containing fabric finishing agent of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com