High-temperature-resistant high-strength tough silicon nitride based wave-transparent composite material and preparation method thereof

A high-strength and toughness, silicon nitride-based technology, used in ceramic products, antennas, applications, etc., can solve the problems of insufficient strength, toughness and wave transmittance of basic wave-transmitting materials, and cannot meet the requirements of high Mach number aircraft. It has strong designability, improves and optimizes performance, and meets the effect of anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

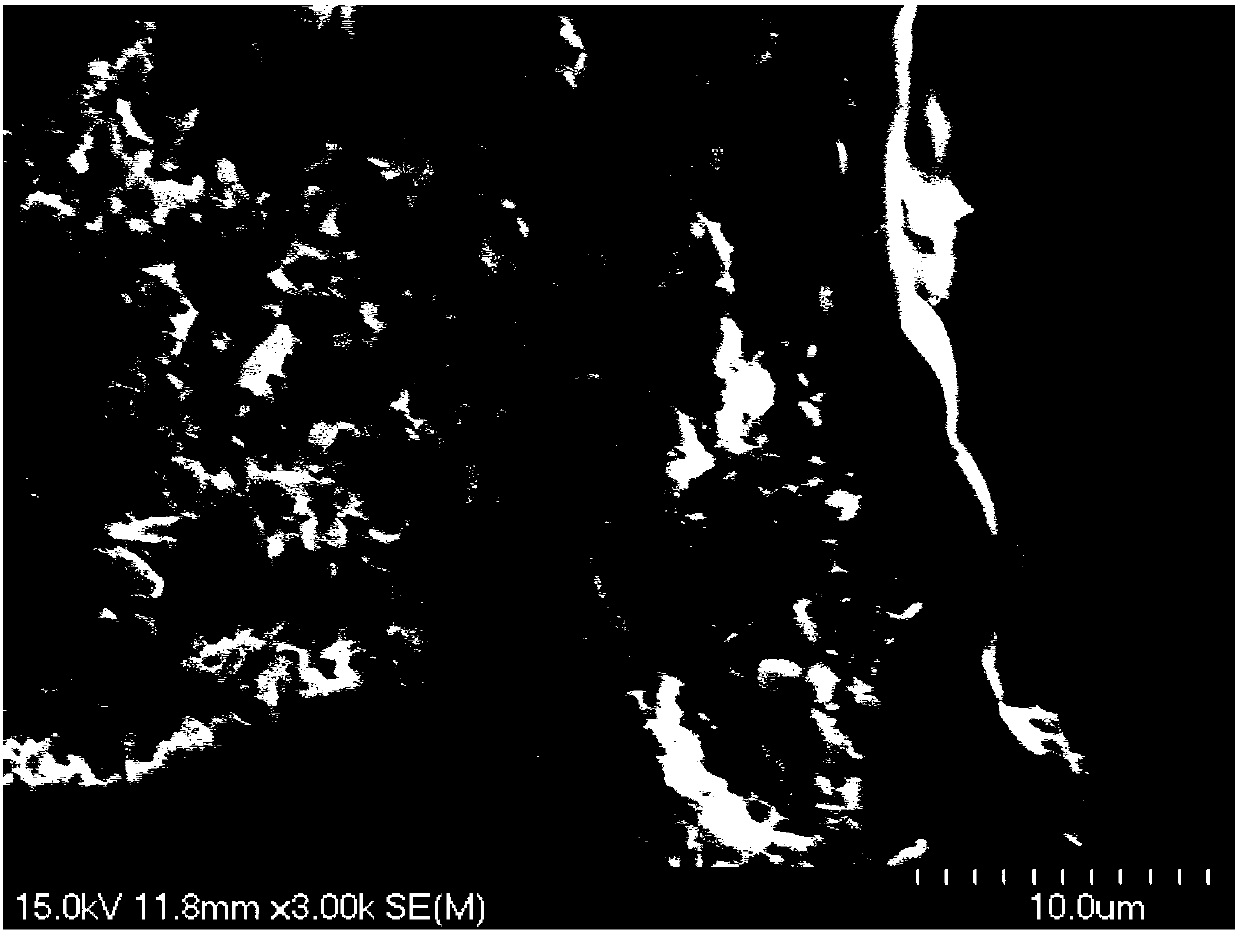

Image

Examples

preparation example Construction

[0027] Step 1.Si 3 N 4 Preparation of whisker blank: the volume fraction is 20-50% Si 3 N 4 Whiskers and 1.5-2.5wt.% of the dispersant polyacrylamine are dissolved in deionized water, and the pH regulator tetramethylammonium hydroxide is added to adjust the pH value of the slurry to 9-11; after that, 4-10wt.% of Monomer acrylamide (AM) and 0.2-1.0wt.% cross-linking agent methylenebisacrylamide (MBAM), ball mill the slurry for 24-36 hours, and vacuum defoam for 10 minutes after mixing evenly; then add 0.2-0.5 wt.% of the initiator ammonium persulfate and 0.02-0.1wt.% of the catalyst tetramethylethylenediamine (TEMED), stirred evenly, poured into a mold, and formed into Si 3 N 4 Whisker blanks.

[0028] Step 2. Si 3 N 4 Drying of the whisker blank: the Si in step 1 3 N 4 The whisker blank is naturally dried at room temperature for 12-36 hours, and then dried in an oven at 50-100°C.

[0029] Step 3. Si 3 N 4 Debinding of the whisker blank: the Si in step 2 3 N 4 The...

Embodiment 1

[0033] Step 1. Si 3 N 4 Preparation of whisker green body: the volume fraction of 30% Si 3 N 4 Whiskers, 1.5wt.% dispersant polyacrylamide were dissolved in deionized water, the pH regulator was tetramethylammonium hydroxide, the pH value was 11, and then 5wt.% monomer AM, 0.25wt.% The cross-linking agent MBAM was ball-milled for 24 hours, the slurry was mixed evenly, and after vacuum defoaming for 10 minutes, 0.4wt.% of the initiator APS and 0.02wt.% of the catalyst TEMED were added, stirred evenly and poured into the mold to obtain Si 3 N 4 Whisker blank;

[0034] Step 2. Si 3 N 4 Drying of the whisker blank: the whisker blank in step 1 was naturally dried at room temperature for 36 hours, and then dried in an oven at 80°C;

[0035] Step 3. Si 3 N 4 Debinding of whisker blanks: put the dried blanks in a horse-boiler furnace, and empty-fire debinding at 500°C for 3 hours to obtain Si 3 N 4 Whisker preform;

[0036] Step 4. Preparation of BN interface: use CVI proc...

Embodiment 2

[0039] Step 1.Si 3 N 4 Preparation of whisker green body: Si with a volume fraction of 35% 3 N 4 Whiskers, 1.5wt.% dispersant polyacrylamide were dissolved in deionized water, the pH regulator was tetramethylammonium hydroxide, the pH value was 11, and then 5wt.% monomer AM, 0.25wt.% The cross-linking agent MBAM was ball-milled for 28 hours, the slurry was mixed evenly, and after vacuum defoaming for 10 minutes, 0.35wt.% of the initiator APS and 0.02wt.% of the catalyst TEMED were added, stirred evenly, and poured into the mold to obtain Si 3 N 4 Whisker blank;

[0040] Step 2. Si 3 N 4 Drying of the whisker blank: the whisker blank in step 1 was naturally dried at room temperature for 36 hours, and then dried in an oven at 80°C;

[0041] Step 3. Si 3 N 4 Debinding of whisker blanks: put the dried blanks in a horse-boiler furnace, and empty-fire debinding at 500°C for 3 hours to obtain Si 3 N 4 Whisker preform;

[0042] Step 4. Preparation of BN interface: use CVI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com