Dust collection device for crusher

A technology of dust removal device and crusher, which is applied in the direction of dust removal, grain processing, and separation of dispersed particles, etc., can solve the problems of lung and respiratory diseases, complex structure of dust removal device, and extremely serious air pollution, etc., and achieve the overall structure Ingenious design, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

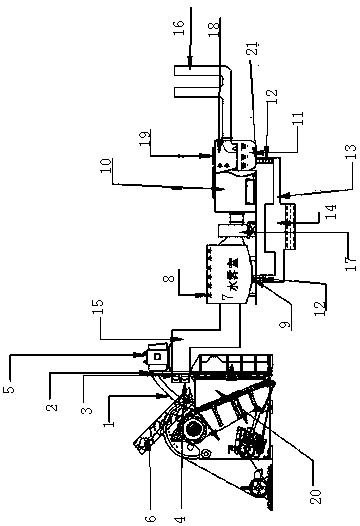

[0016] Embodiment 1: see figure 1 , a crusher dust removal device, the crusher dust removal device includes a draft assembly, a dust removal assembly, a water circulation assembly and an air supply and exhaust assembly; the exhaust assembly is located at the front end of the dust removal assembly; the dust removal assembly is located above the water circulation assembly; The exhaust assembly is located between the exhaust assembly and the dust removal assembly. The design structure is simple and clear, the components are closely connected and do not affect each other, the required parts are easy to replace, and it is easy to maintain the product during use in the future. The exhaust assembly includes a windshield 1, a windshield Bracket 2, paddle exhaust fan 3, exhaust fan anti-collision barrier 4 and high-efficiency low-noise fan 5; the windshield is located at the upper end of the crusher and fixed on the windshield bracket; the windshield bracket is installed on the upper p...

Embodiment 2

[0017] Example 2: see figure 1 , as an improvement of the present invention, the dust removal assembly includes a water mist chamber 7, a high-pressure water mist nozzle 8, a drainage hole 9, a water film pressurization chamber 10 and an impact type water film dust removal section 11; the water mist chamber is installed Between the air supply pipe and the blower; the high-pressure water mist nozzle is located at the top of the water mist chamber; the drainage hole is located at the bottom of the water mist chamber; the water film pressurization chamber is located on the right side of the blower; the impact water film dust removal The segment is located on the right side of the water film pressurization chamber. The high-pressure water mist nozzle in the water mist chamber can spray a large amount of water mist. The water mist is mixed with the dust mist transported into the water mist chamber by the air supply pipe under the action of power. Through the kinetic energy contai...

Embodiment 3

[0018] Embodiment 3: see figure 1 , as an improvement of the present invention, the water mist chamber 7 and the floor of the impingement water film dedusting section are designed to be concave arcs. The design of the arc-shaped ground can make the water flow better to the sewage outlet, reduce the accumulation of indoor waste and water flow, and also facilitate the later indoor cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com