Preparation and application of essence of thermal reaction intermediate with roasted and nutty aroma for tobacco

A heat-reaction, nut-flavored technology, applied in the field of heat-reaction intermediate tobacco flavor preparation, can solve the problems of unsafe, inability to realize the industrialized production of amino sugar compounds, high production cost, etc., and achieves soft smoke and good harmony , aroma quantity and aroma quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

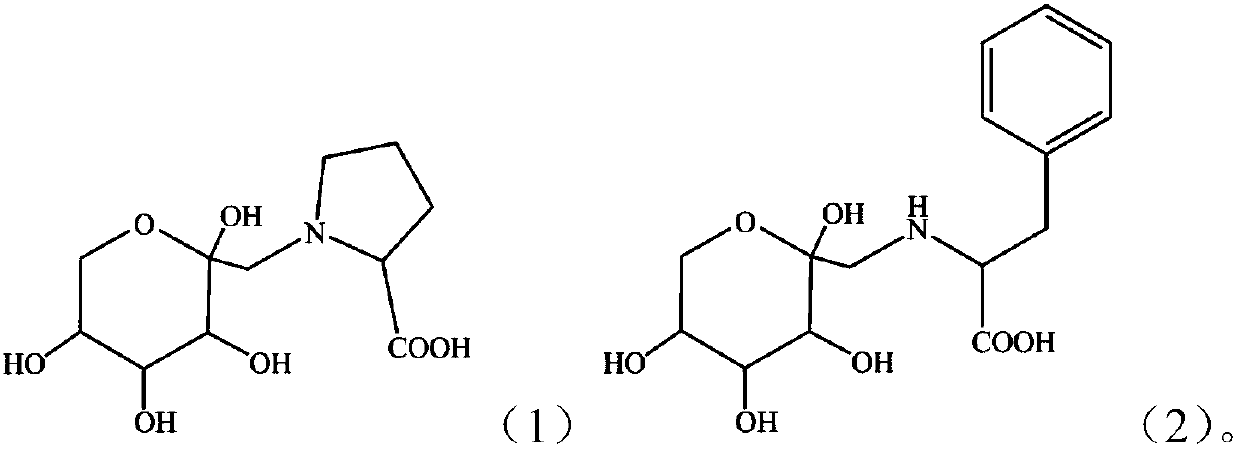

[0035] Take 18kg of phenylalanine and 40kg of galactose, add 800kg of water to form a solution, adjust the pH to 7.5, place the resulting solution in a Maillard reactor, and perform a Maillard reaction at 100°C for 80 minutes to obtain a reaction solution. The reaction solution was simultaneously evaporated and reacted for 20 minutes in a negative pressure environment at 80° C. to obtain deoxyamino sugars.

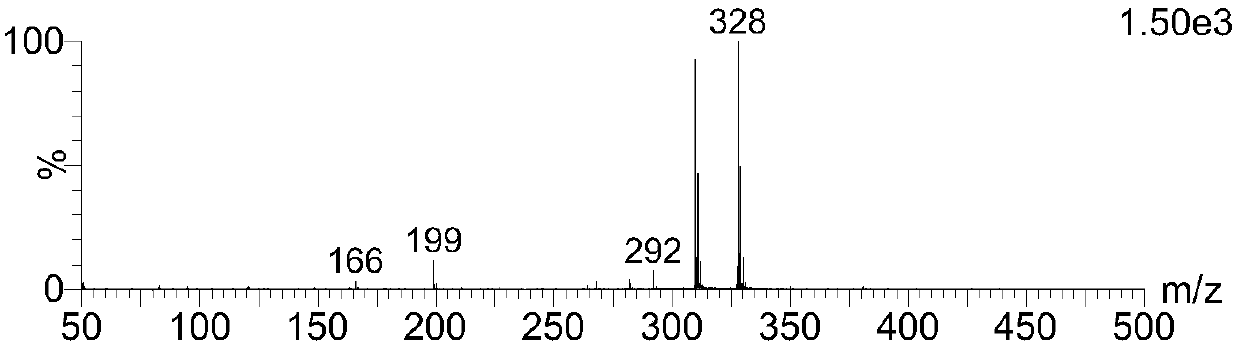

[0036] After the gained solid is dissolved in water, it is analyzed by high-performance liquid chromatography tandem mass spectrometry analysis technique, obtains mass spectrogram ( figure 1 ).

[0037] After dissolving the obtained solid in water, add it to the cigarette, the addition amount is respectively The cigarette samples were subjected to sensory evaluation by professional evaluators, and the smoking evaluation results are shown in Table 1.

[0038] Table 1 Sensory evaluation and smoking effect of cigarettes added with galactose-phenylalanine system amino sug...

Embodiment 2

[0041] Take 21kg proline and 66kg fructose, add 800kg water to form a solution. Adjust the pH of the solution to 7, place the obtained solution in a Maillard reactor, and perform a Maillard reaction at 110° C. for 50 minutes to obtain a reaction solution. The reaction solution is evaporated and reacted simultaneously in a negative pressure environment of 90° C. for 30 minutes. Obtained deoxyaminosugar solid.

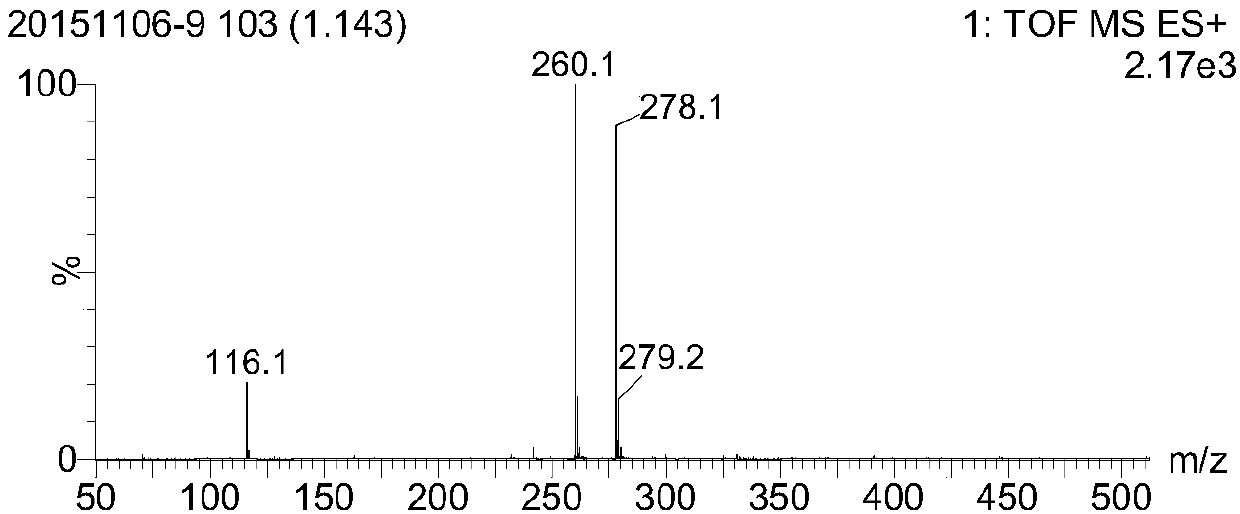

[0042] After the gained solid is dissolved in water, it is analyzed by high-performance liquid chromatography tandem mass spectrometry analysis technique, obtains mass spectrogram ( figure 2 ).

[0043] After dissolving the obtained solid in water, add it to the cigarette, the addition amount is respectively The cigarette samples were subjected to sensory evaluation by professional evaluators, and the smoking evaluation results are shown in Table 2.

[0044] Table 2 Sensory evaluation and smoking effect of cigarettes added fructose-proline system amino sugar flavo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com