Automotive shock absorber with micro porous metal fiber felt as damping element

A technology of metal fiber felt and metal fiber, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem of insufficient absorption of vibration energy due to piston damping, limited throttle area of valve plate, and vibration reduction The hydraulic oil viscosity of the device is low, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

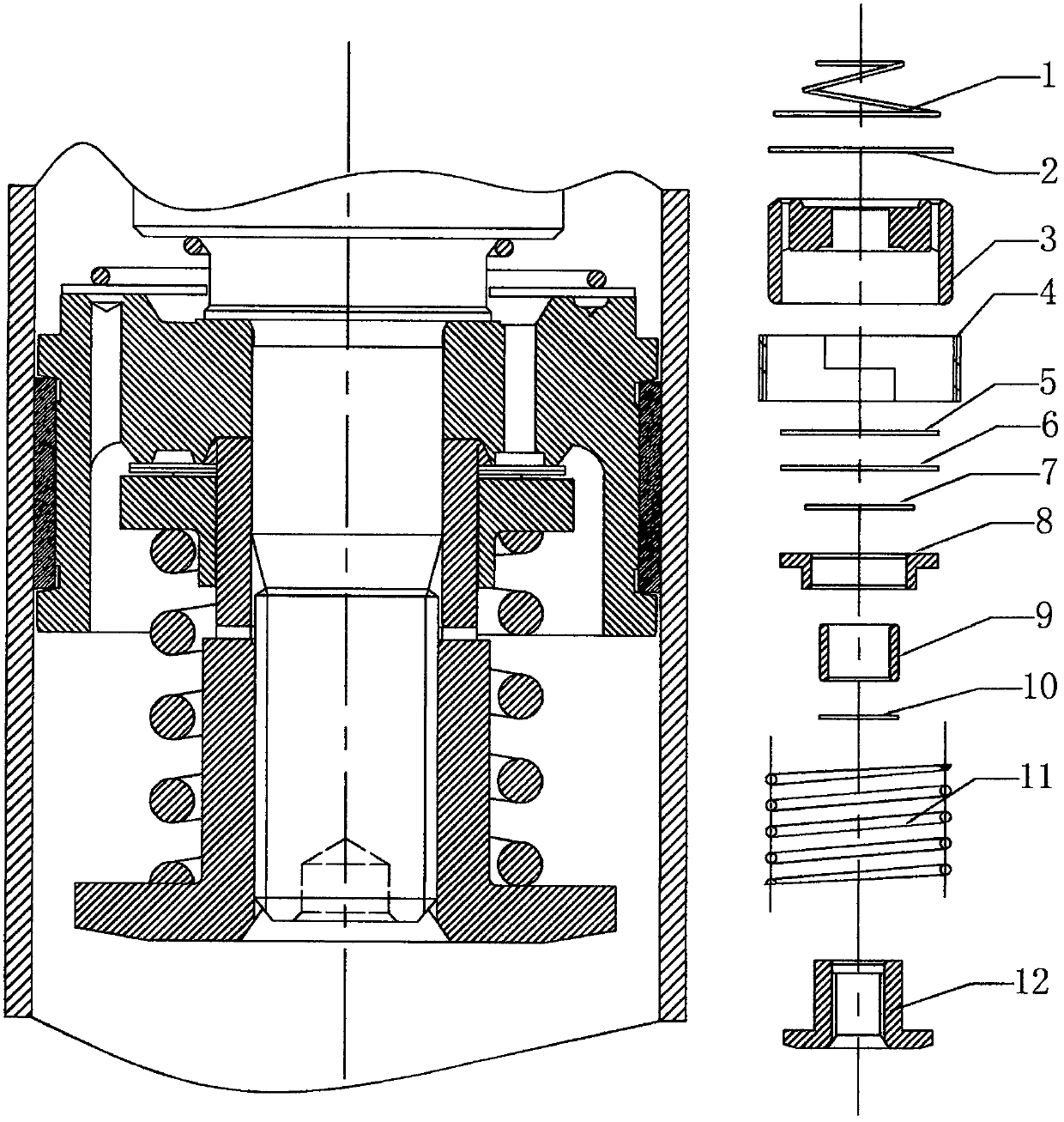

[0023] A shock absorber according to the principle of the present invention mainly includes the following components: a steel cylinder 1 with a diameter of 70 mm, an upper oil seal assembly 2, a pressing element 3, and a microporous metal fixed on the upper part of the cylinder to play a damping role. The fiber felt disk 4 has a porosity of 75% and a minimum pore size of 25-30 microns. The metal fiber felt is made of 25 layers of 320-mesh stainless steel mesh and then vacuum sintered. The upper and lower ends are respectively made of porous steel plates with a thickness of 3 mm. For the protective layer, the inner circle and the adjacent parts of the piston rod are welded with steel pipes with a wall thickness of 5 mm and metal fiber felt before machining. The metal fiber felt used in disc 4 has an air permeability of 330-400L at room temperature without oil. / (min*dm 2 ) (test standard according to ISO 4022); the hydraulic oil inside the shock absorber adopts high-viscosity h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com