Chipfryer

A frying machine and potato chips technology, which is applied in the direction of oil/fat baking, etc., can solve the problems of increasing production cost, difficult to meet the quality requirements, oil deterioration, etc., and achieve the effect of improving production efficiency, ensuring frying quality and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

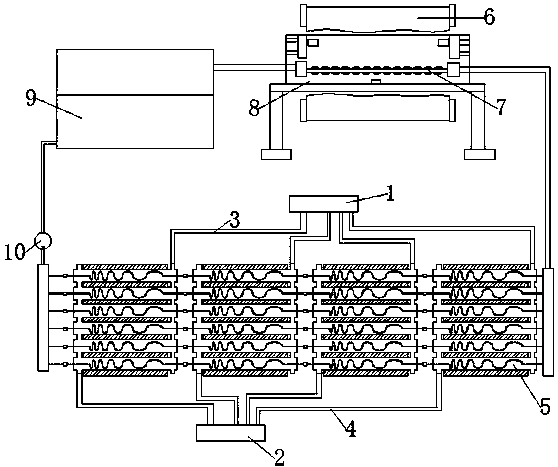

[0039] Such as image 3 As shown, a potato chip fryer includes a transmission mechanism 6, a frying mechanism 8 and a heating system.

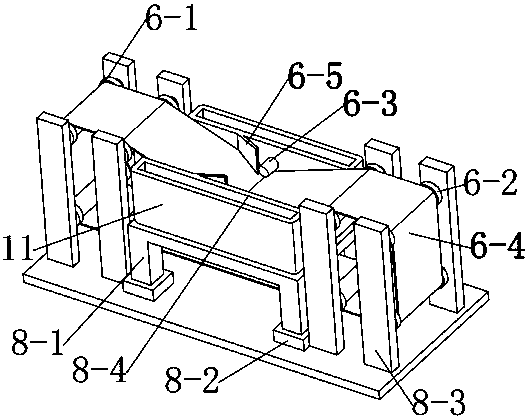

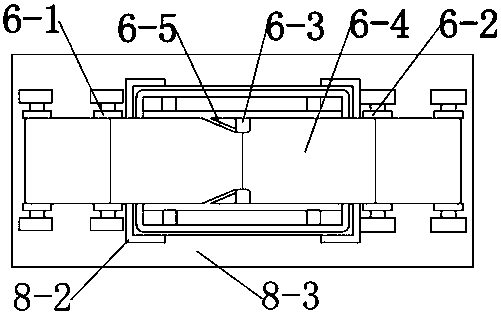

[0040] Such as figure 1 , 2Shown in and 3, frying mechanism 8 comprises oil tank 11, temperature sensor, support frame 8-1, heat insulation base 8-2, installation frame 8-3 and baffle plate 8-4. A temperature sensor is arranged at the bottom of the inner chamber of the oil tank. The temperature sensor is immersed in the cooking oil in the oil tank. Two baffle plates are arranged in the center of the oil tank 11 . The two ends of the baffle plate are fixed to the two opposite inner walls of the oil groove 11, the top is set flush with the upper edge of the oil groove 11, and the bottom is set at a distance from the bottom surface of the oil groove 11 inner cavity. The top surface of support frame 8-1 is fixed with the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com