Method for preparing carbon catalyst based on carbon template-induced Fe-N growth and carbon catalyst

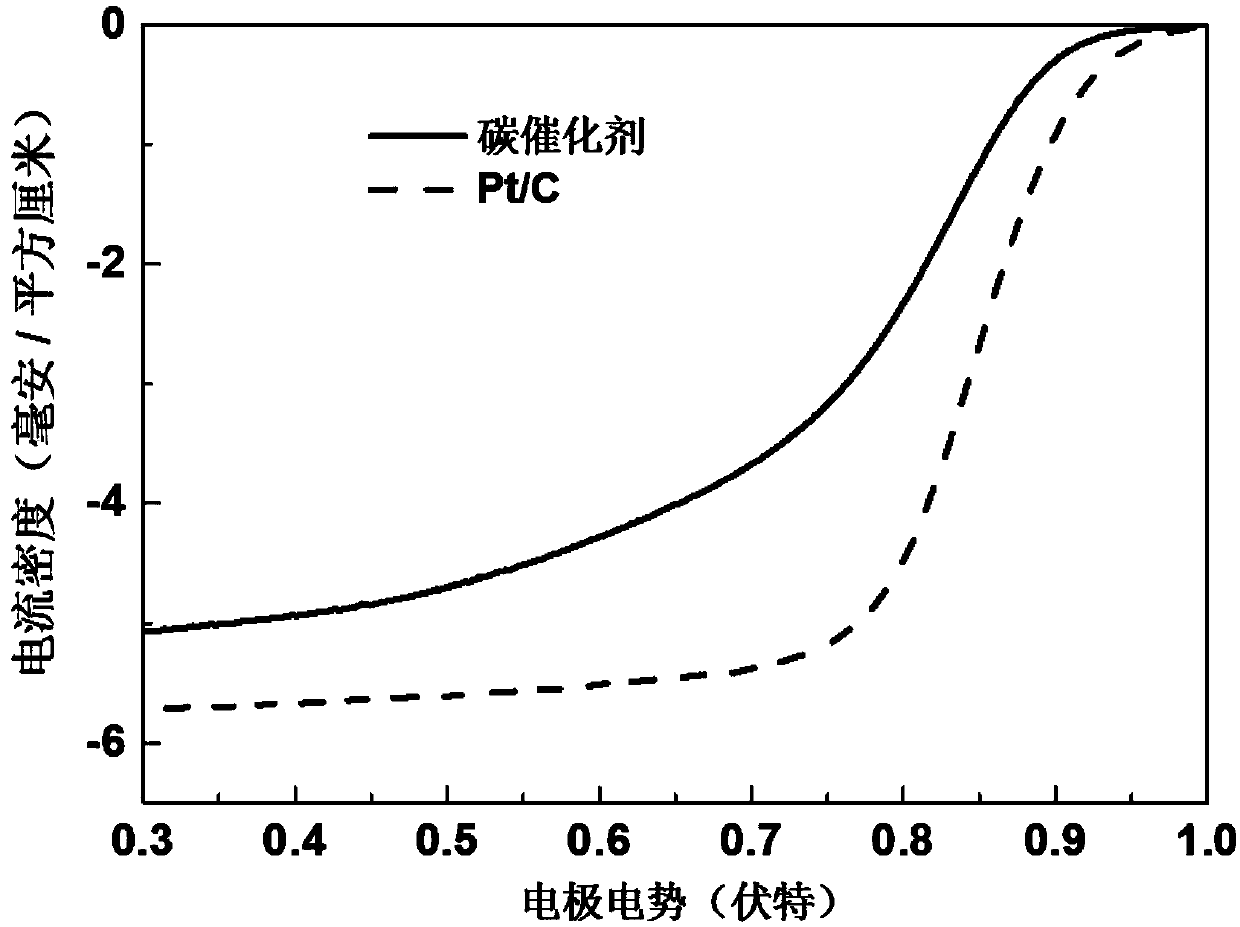

A carbon catalyst and carbon template technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low catalyst activity and limited application, and achieve favorable fixation and protection, good conductivity, and rich pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Preparation of Fe, N co-doped carbon catalyst without carbon template:

[0051] Weigh a certain mass of melamine and FeSO 4 ·7H 2 O powder, dispersed in water (ethanol can be added to promote dissolution), after mixing thoroughly, the catalyst precursor powder is obtained by rotary evaporation or ultrasonic heating, and placed in a tube furnace under the protection of high-purity argon inert atmosphere , pyrolyzed at 900°C for 1 h to obtain a black Fe, N co-doped carbon catalyst.

[0052] 2) Catalyst species composition and content characterization:

[0053] Combining multiple characterization techniques to analyze the composition of the catalyst prepared without carbon templates: in the XRD curve, there are obvious characteristic peaks of elemental Fe and Fe carbides, and at the same time, some weak Fe-N x Species characteristic peaks. The XPS results show that the N content is about 4.5 at%, which is composed of pyridine N, pyrrole N, graphite N and "N-O" types...

Embodiment 2

[0059] 1) Preparation of Fe and N co-doped carbon catalysts when carbon particles are used as carbon templates:

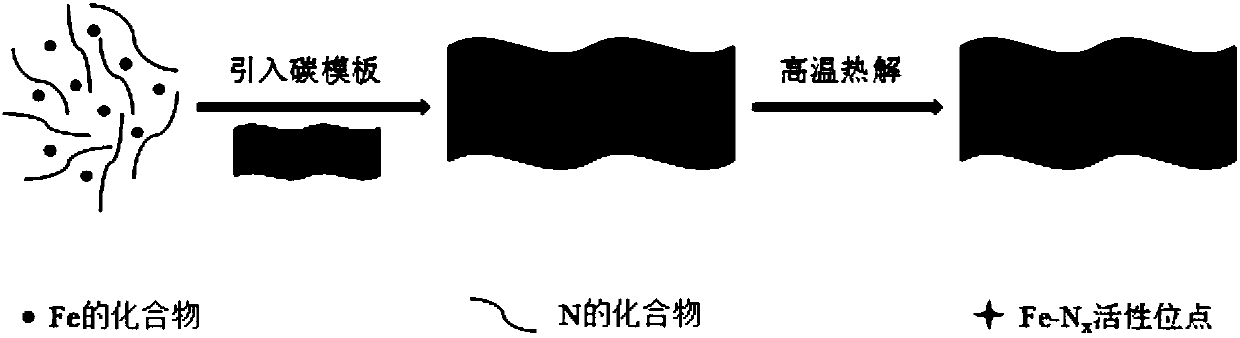

[0060] An aqueous solution of Vulcan XC-72 carbon particles was wet ball milled and freeze-dried, and the resulting powder was added to melamine and FeSO 4 ·7H 2 In the aqueous dispersion of O (can be added with ethanol to promote dissolution), after fully mixing, the catalyst precursor powder is obtained by rotary evaporation or ultrasonic heating, and it is placed in a tube furnace under the protection of a high-purity argon inert atmosphere. , pyrolyzed at 900°C for 1 h to obtain a black Fe, N co-doped carbon catalyst. The process of carbon template-induced active site growth is as follows: figure 2 As shown, the TEM spectrum of the catalyst is shown as image 3 shown.

[0061] 2) Catalyst species composition and content characterization:

[0062] Combining multiple characterization techniques to conduct an in-depth analysis of the composition of catalysts...

Embodiment 3

[0069] 1) Preparation of Fe, N co-doped carbon catalyst when graphene is used as carbon template:

[0070] An aqueous solution of graphene was wet ball milled and then freeze-dried, and the resulting powder was added to melamine and FeSO 4 ·7H 2 In the aqueous dispersion of O (can be added with ethanol to promote dissolution), after fully mixing, the catalyst precursor powder is obtained by rotary evaporation or ultrasonic heating, and it is placed in a tube furnace under the protection of a high-purity argon inert atmosphere. , pyrolyzed at 900°C for 1 h to obtain a black Fe, N co-doped carbon catalyst.

[0071] 2) Catalyst species composition and content characterization:

[0072] In-depth analysis of the composition of catalysts prepared when graphene was used as a carbon template by combining multiple characterization techniques: some Fe-N x The characteristic peaks of species, no characteristic peak signals of elemental Fe and Fe carbides. The XPS results show that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com