Lithium-sulfur battery functional composite diaphragm and preparation method therefor

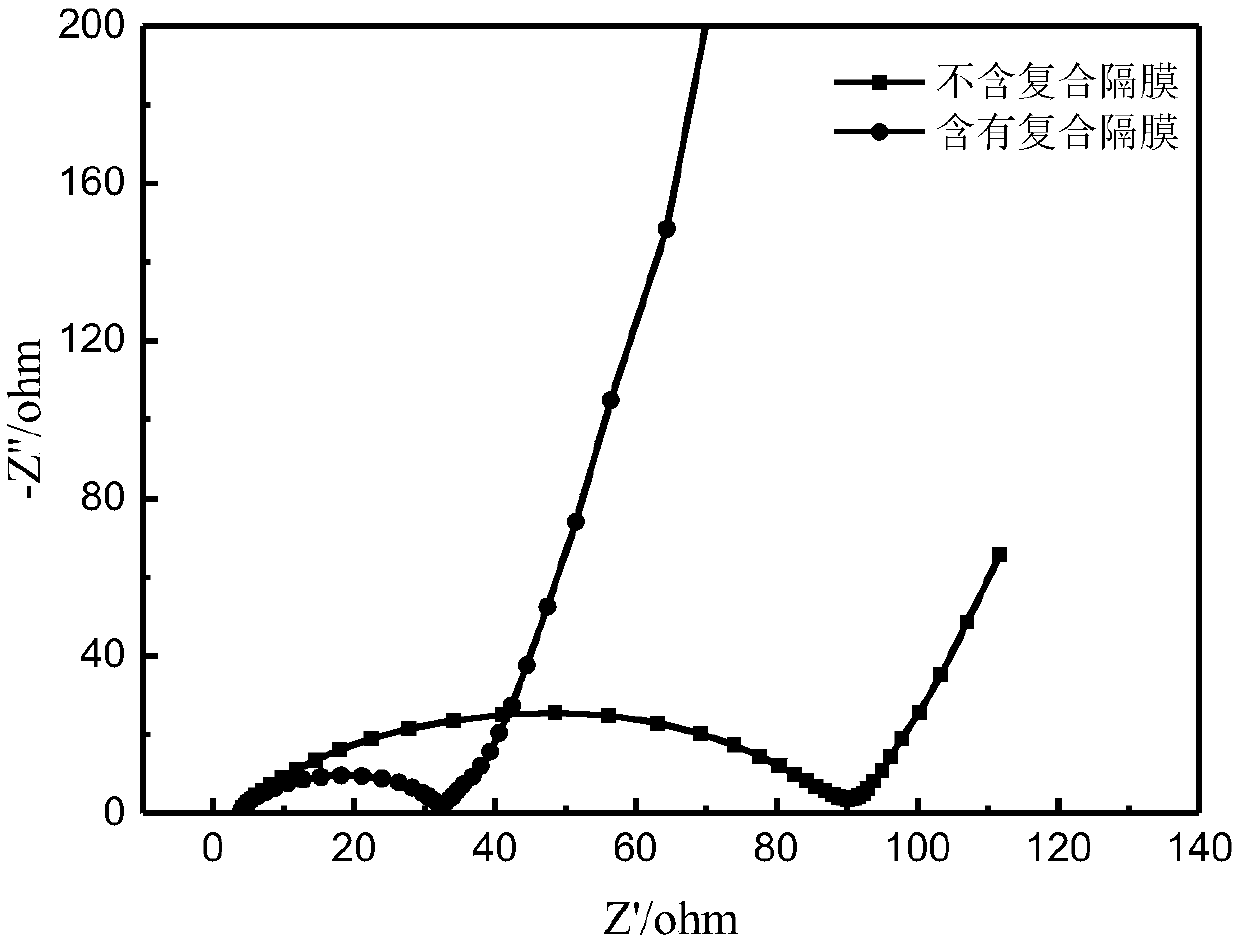

A lithium-sulfur battery and composite separator technology, which is applied to lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of insufficient stability of electrolyte interface film, lithium negative electrode dendrite growth, and poor conductivity of positive electrode materials. , to achieve the effect of inhibiting the shuttle effect of polysulfide ions, reducing impedance and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

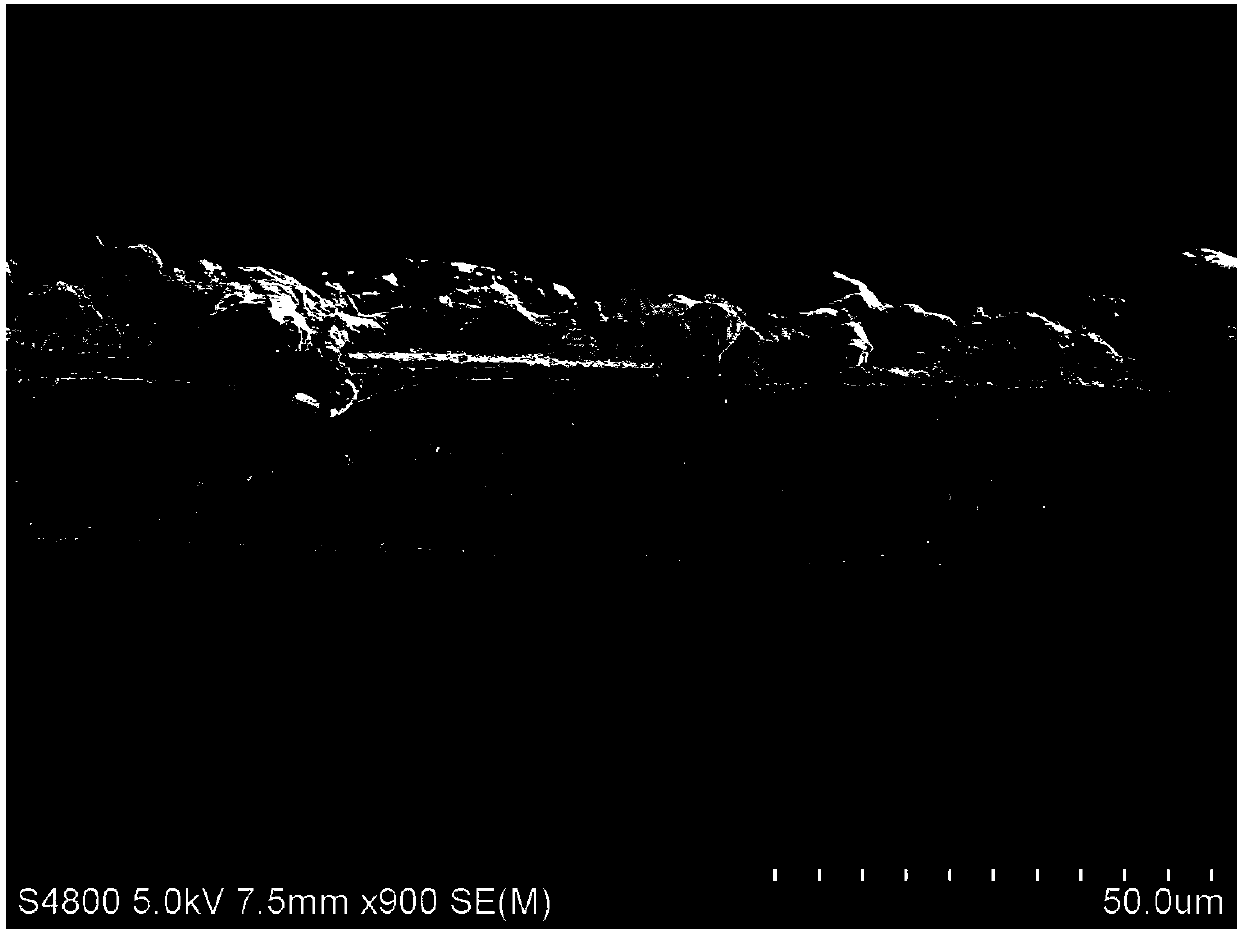

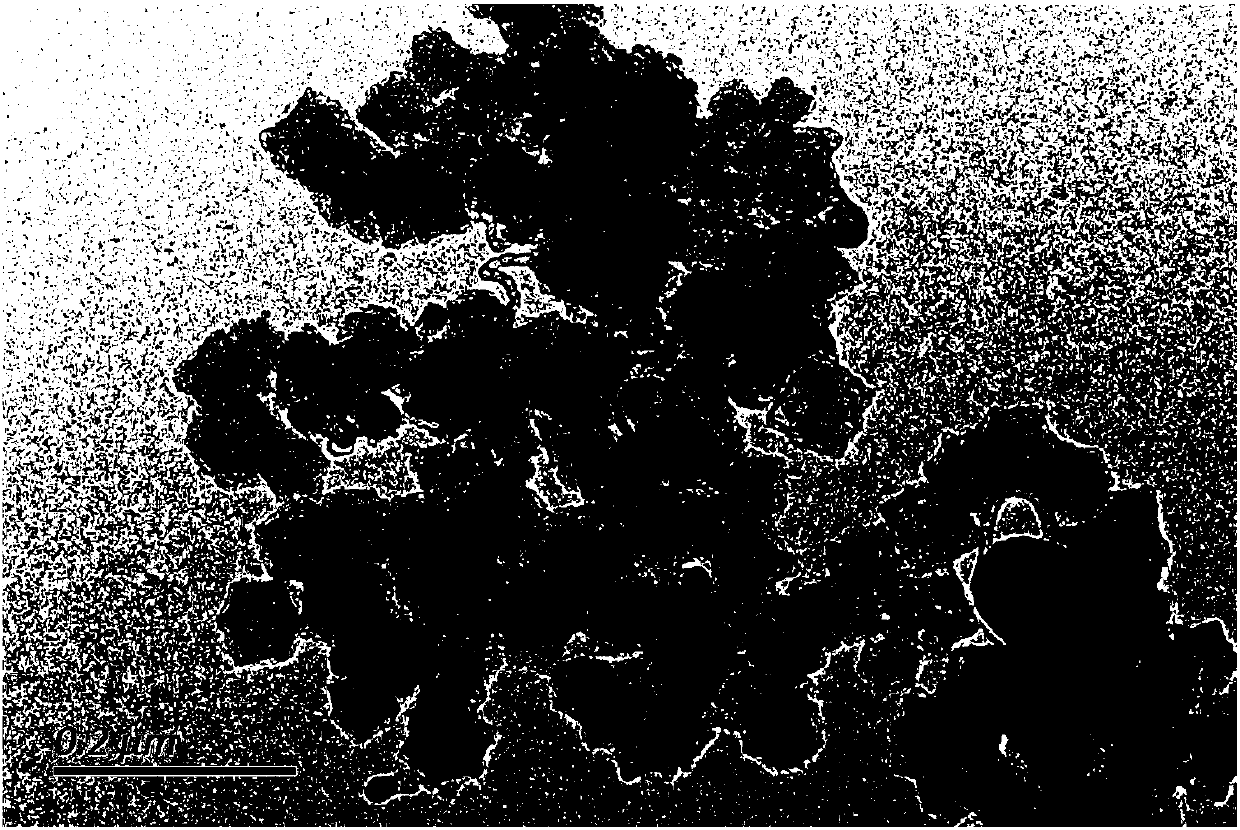

[0037] At room temperature, 2.8g Zn(NO 3 ) 2 ·6H 2 O and 0.548g Co(NO 3 ) 2 ·6H 2O was dissolved in 160ml of anhydrous methanol, and at the same time, 7.4g of 2-methylimidazole was dissolved in 160ml of anhydrous methanol, and the dissolved 2-methylimidazole solution was slowly poured into the Zn-Co mixed solution with magnetic stirring for 2h and mixed evenly , left to stand for 12 hours, centrifuged, washed with anhydrous methanol three times to remove impurities, and the obtained purple precipitate was dried in an oven at 60°C to obtain BMZIF-5. The obtained BMZIF-5 was calcined at 1000° C. for 5 h in an argon atmosphere in a tube furnace to obtain a graphitized carbon material doped with nitrogen and cobalt. Then 65 mg of nitrogen-cobalt-doped graphitized carbon material and polyvinylidene fluoride were uniformly mixed at a mass ratio of 13:2 to obtain a functionalized coating. The functionalized coating is coated on a polypropylene separator substrate with a thickne...

Embodiment 2

[0048] At room temperature, 1.68g Zn(NO 3 ) 2 ·6H 2 O and 1.644g Co(NO 3 ) 2 ·6H 2 O was dissolved in 160ml of anhydrous methanol, and at the same time, 3.7g of 2-methylimidazole was dissolved in 160ml of anhydrous methanol, and the dissolved 2-methylimidazole solution was slowly poured into the Zn-Co mixed solution with magnetic stirring for 2h and mixed evenly , left to stand for 12 hours, centrifuged, washed with anhydrous methanol three times to remove impurities, and the obtained purple precipitate was dried in an oven at 60°C to obtain BMZIF-1. The obtained BMZIF-1 was calcined at 1000° C. for 5 h in an argon atmosphere in a tube furnace to obtain a graphitized carbon material doped with nitrogen and cobalt. Then 60 mg of nitrogen-cobalt-doped graphitized carbon material and polyvinylidene were uniformly mixed at a mass ratio of 6:1 to obtain a functionalized coating. The functionalized coating is coated on a polypropylene separator substrate with a thickness of 42...

Embodiment 3

[0059] At room temperature, 1.653g Zn(CH 3 COO) 2 2H 2 O and 0.938gCo(CH 3 COO) 2 4H 2 O was dissolved in 160ml of anhydrous methanol, and at the same time, 7.4g of 2-methylimidazole was dissolved in 160ml of anhydrous methanol, and the dissolved 2-methylimidazole solution was slowly poured into the Zn-Co mixed solution with magnetic stirring for 2h and mixed evenly , left to stand for 12 hours, centrifuged, washed with anhydrous methanol three times to remove impurities, and the obtained purple precipitate was dried in an oven at 60°C to obtain BMZIF-2. The obtained BMZIF-2 was calcined at 1000° C. for 5 h in an argon atmosphere in a tube furnace to obtain a graphitized carbon material doped with nitrogen and cobalt. Then 65 mg of nitrogen-cobalt-doped graphitized carbon material and polyvinylidene fluoride were uniformly mixed at a mass ratio of 13:2 to obtain a functionalized coating. The slurry is coated on a polypropylene separator with a thickness of 10 μm, and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com