Chip cooling system

A cooling system and chip technology, applied in refrigerators, refrigeration and liquefaction, machines using electromagnetic/magnetic effects, etc., can solve the problems of computer performance degradation, high operating noise, poor portability, etc. Chip temperature, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

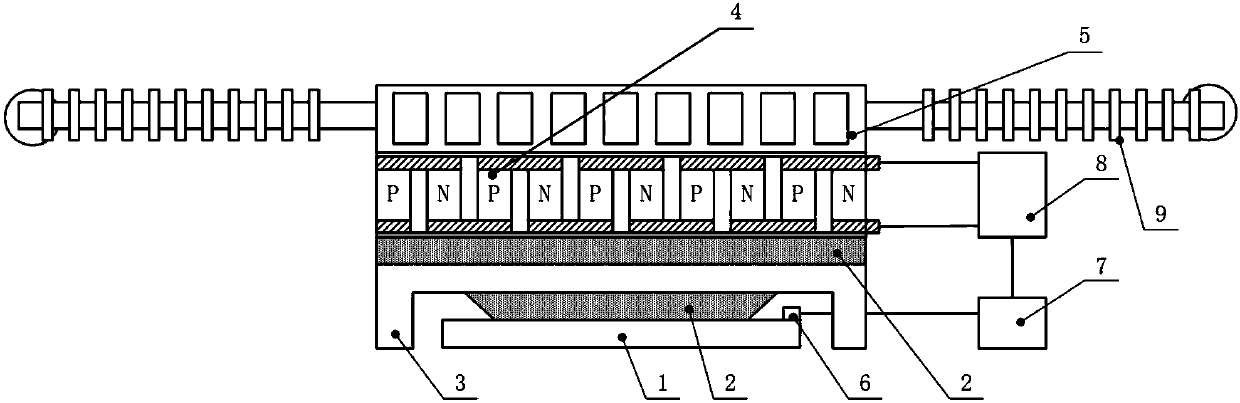

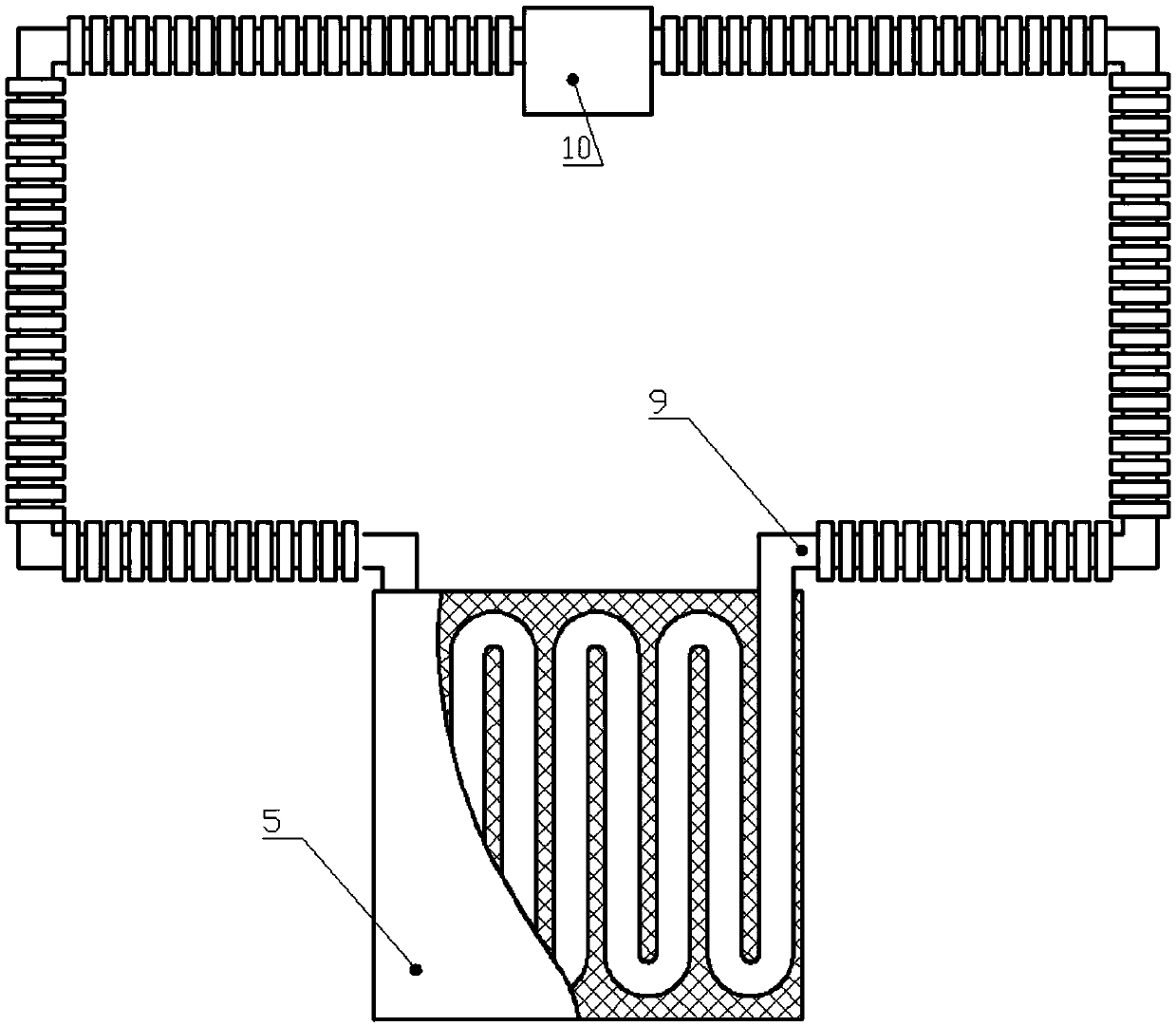

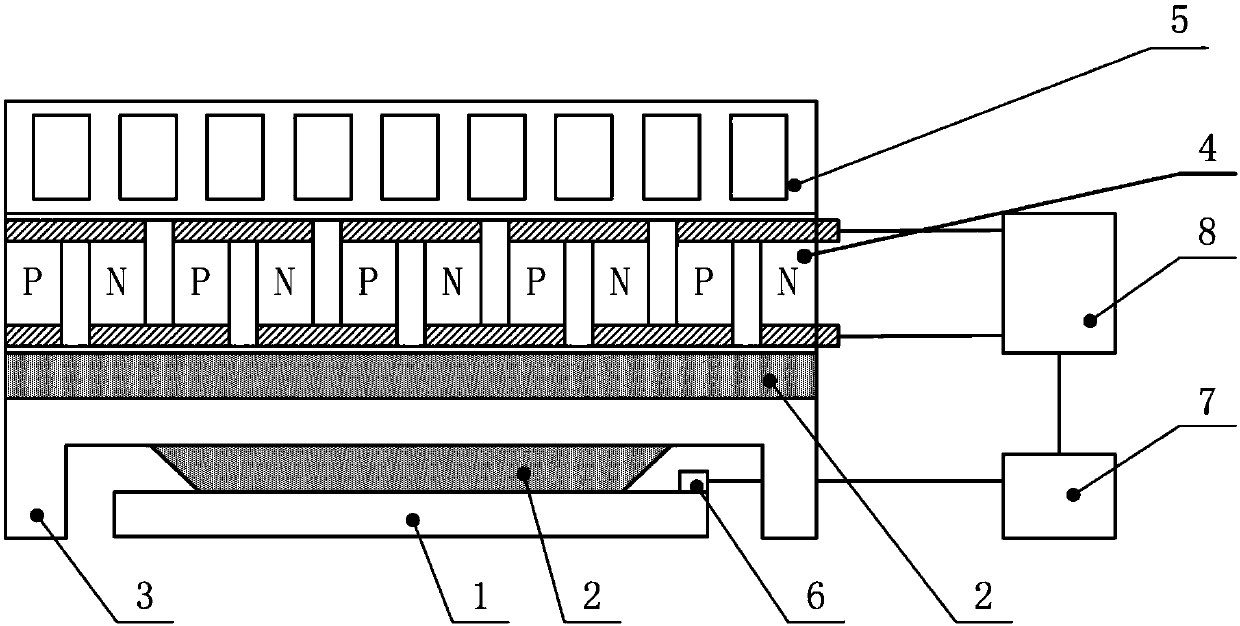

[0034] like Figure 1 to Figure 2 Shown: the present invention includes a semiconductor refrigerator 4 for active conveying heat exchange and a chip radiator 5 for passive convection heat exchange. The chip radiator 5 is provided with zigzag micro-channels side by side, and the micro-channel is connected with a circulation pipe 9 at the same time to form a circulation loop. The circulation loop is filled with liquid I, and liquid I is a water-based liquid nanofluid of suspended copper nanoparticles. Compared with traditional pure water, it has higher thermal conductivity; an electroosmotic pump 10 is arranged on the circulation pipeline 9, and the electroosmotic pump 10 is connected to a power supply for power supply work, which can provide considerable flow under the premise of low power consumption.

[0035] see image 3 , the bottom surface of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com