A semi-automatic and fully automatic correction method for the offset of the tool head of the swash plate servo tool magazine

An automatic deviation correction, semi-automatic technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of tool drop, machine tool use cost, increased maintenance cost of machine tool manufacturers, damage to tool claws, etc. The effect of improving the time of the machine tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

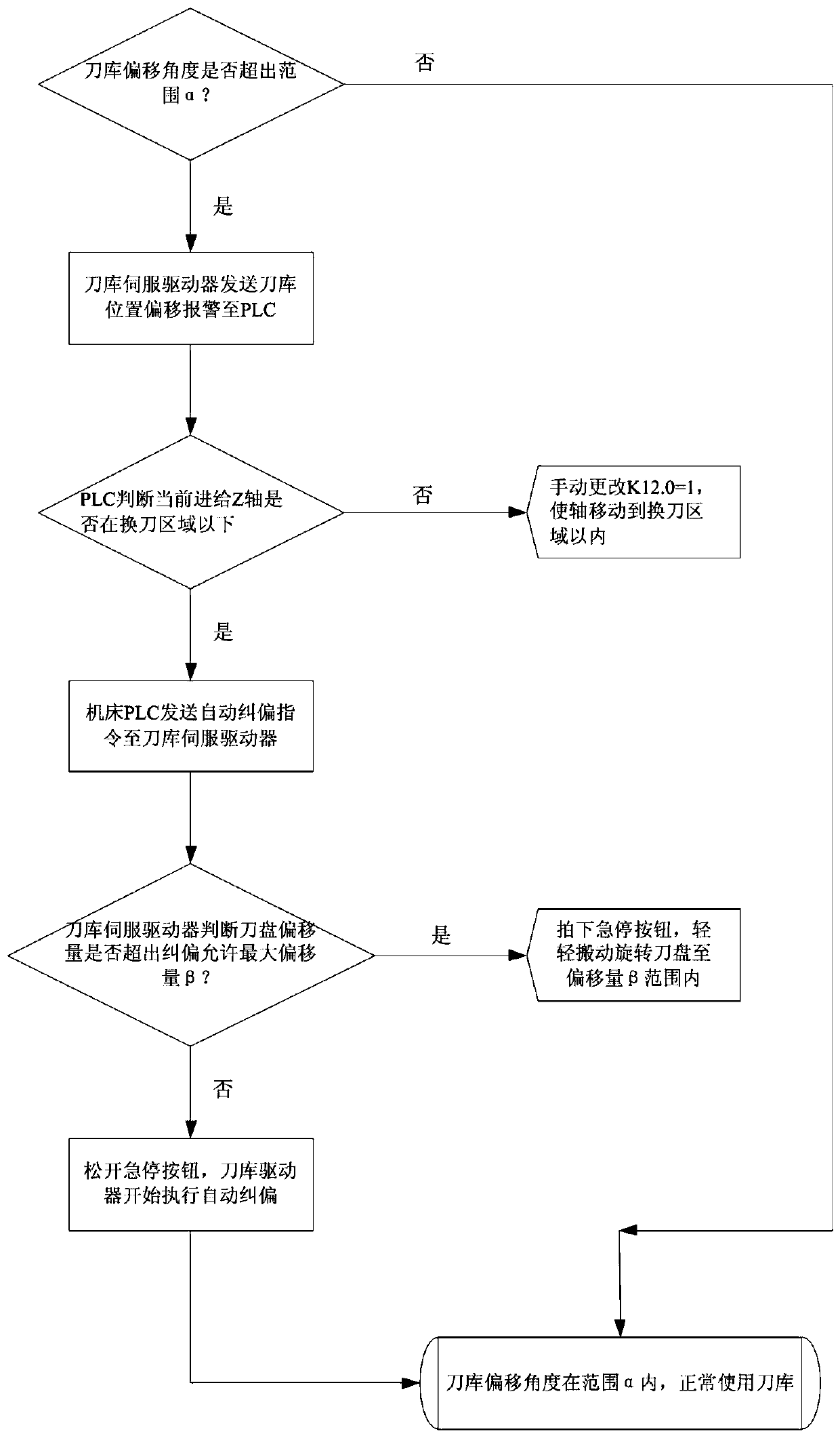

[0044] This embodiment discloses a semi-automatic and fully automatic deviation correction method for the offset of the swash plate type servo tool magazine, which is used to realize the automatic deviation correction process of the servo tool magazine for drilling and tapping centers. The process is controlled by a programmable logic controller PLC , Tool magazine servo drive to control the automatic deviation correction function of the servo tool magazine motor, to realize that after power-on, the angular position of the servo tool magazine and the tool magazine can be quickly, accurately and automatically corrected to the correct position after certain conditions are met. .

[0045] The method of the invention is implemented on the basis of the servo drive and the motor of an absolute type or an absolute position encoder, and any drive system composed of any encoder has the same effect.

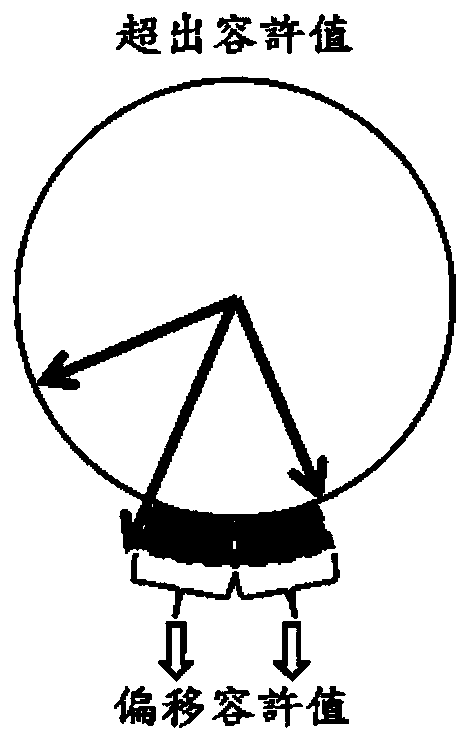

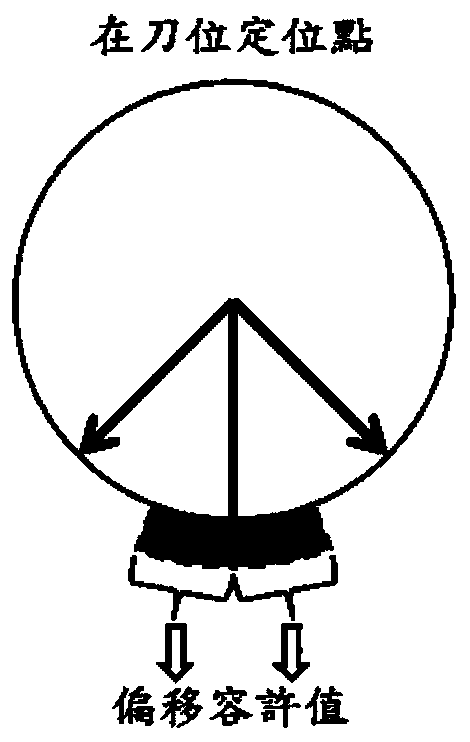

[0046] Among them, the application conditions satisfied by the correction method are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com