Low-pressure testing table for oxygen bottle regulators

A technology of regulators and test benches, which is applied in the direction of container filling methods, container discharge methods, gas/liquid distribution and storage, etc. It can solve the problems of inaccurate adjustment of output gas pressure and inability to detect the performance of control valves, etc., to achieve detection Full range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

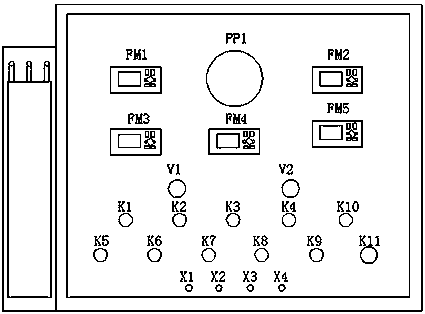

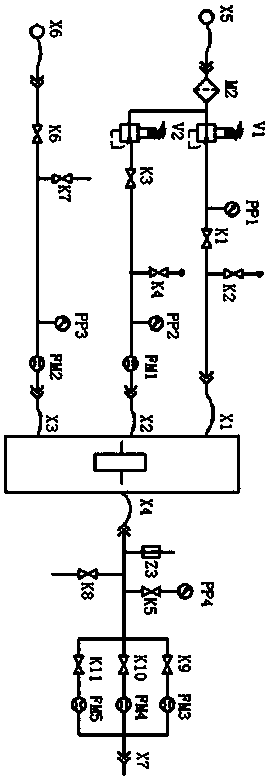

[0038] combined with figure 1 and figure 2As shown, a low-pressure test bench for an oxygen cylinder regulator includes a gas source inlet X5, a vacuum source inlet X6, and an exhaust port X7. One branch and the second branch, the output end of the first branch and the output end of the second branch are respectively provided with the inlet port X1 of the tested part and the inlet port X2 of the tested part, and the inlet of the vacuum source X6 is connected with a third branch for providing a vacuum source to the tested part, the output end of the third branch is provided with the air inlet port X3 of the tested part, and the exhaust port X7 is connected with an output branch. The input end of the output branch is provided with the air outlet interface X4 of the tested piece, and the air inlet interface X1 of the tested piece, the air inlet interface X2 of the tested piece and the air inlet interface X3 of the tested piece are respectively connected to the air inlet port of...

Embodiment 2

[0042] On the basis of Example 1, in conjunction with the attached figure 1 and figure 2 As shown, a filter M2 for filtering gas impurities is also connected between the gas source inlet X5 and the first branch and the second branch.

[0043] working principle:

[0044] A filter M2 is connected between the gas source inlet X5 and the first branch and the second branch to filter impurities from the gas entering the first branch and the second branch to avoid clogging of impurities and the display accuracy of the image pressure gauge .

Embodiment 3

[0046] On the basis of embodiment 2, in conjunction with the attached figure 1 and figure 2 As shown, the first branch includes a main pipeline input pressure regulating decompression valve V1 connected to the filter M2, and the main pipeline input pressure regulating decompression valve V1 is connected with the first main pipeline input regulating needle valve K1. At one end, a pressure gauge PP1 is connected between the main pipeline input pressure regulating pressure reducing valve V1 and the first end of the main pipeline input regulating needle valve K1, and the second end of the main pipeline input regulating needle valve K1 is connected to the The air inlet port X1 of the tested part, the main pipe bypass output cut-off valve K2 is connected between the second end of the main pipe input regulating needle valve K1 and the air inlet port X1 of the tested part.

[0047] working principle:

[0048] After the gas passes through the filter M2 to filter impurities from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com