Leaky wave detection method

A detection method and leaky wave technology, which can be used in measuring devices, measuring electrical variables, instruments, etc., can solve the problems of microwave leakage of microwave ovens and human body hazards, and achieve the effect of comprehensive detection range and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

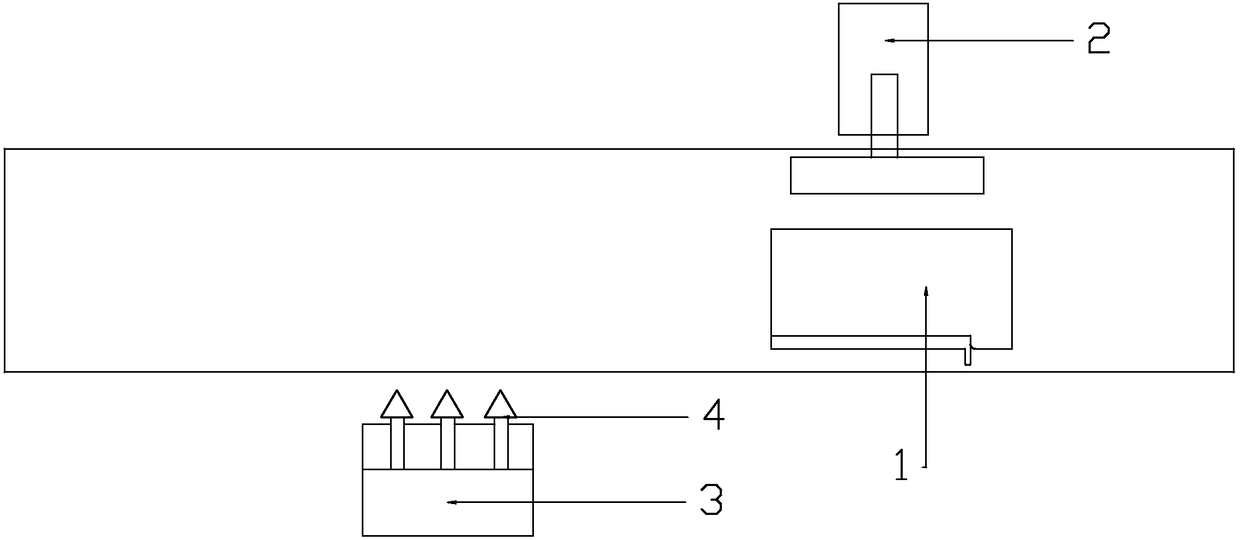

[0022] refer to figure 1 , the present invention is a kind of leakage detection method, comprises the following steps:

[0023] 1). Transfer the microwave oven 1 towards the detection device 3, and use the push device 2 to push the microwave oven 1 to the detection position, and turn on the power of the microwave oven 1, so that the microwave oven 1 is in the working state;

[0024] 2). Using a number of detection probes 4 on the detection device 3 to detect the leaked wave values of multiple detected positions of the microwave oven 1, each detection probe 4 moves relative to the microwave oven 1 along a preset trajectory, and measures the Leakage value of position;

[0025] 3). The detection device 3 compares the value measured by each detection probe 4 with the standard value, and judges the qualified degree of the microwave oven 1;

[0026] 4). Turn off the power of the microwave oven 1 to complete the detection.

[0027] Specifically, when this leakage wave detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com