Method for whole hole replacement of existing bridge

A technology for bridges and bridge bridges, which is applied in the field of the whole hole replacement construction of existing simply-supported T-beam diseased bridges of existing railways, can solve the problems of high hoisting risk factor, great influence of traveling equipment, and difficult construction operations, and achieves simple construction operation and high quality. The effect of guaranteeing and facilitating personnel operations and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

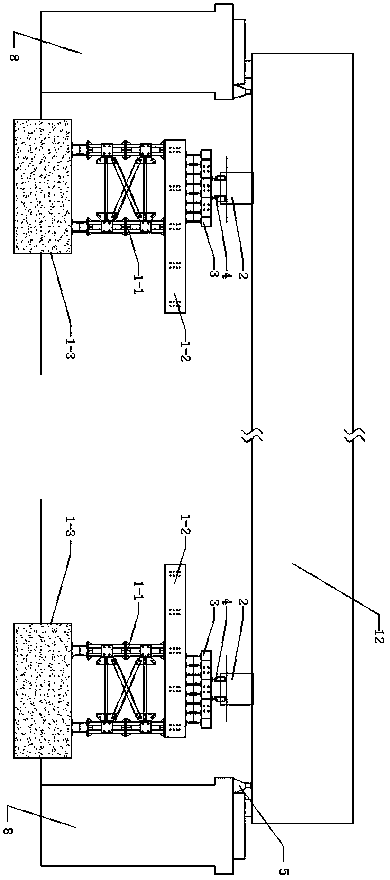

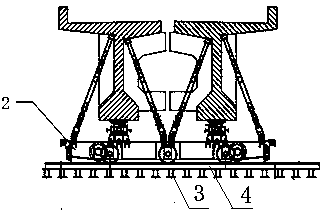

[0034] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0035] As can be seen from the accompanying drawings, the method for replacing the entire bridge hole in the existing bridge includes the following steps,

[0036] Step 1: Concrete foundation 1-3 construction shall be carried out according to the conditions of the road under the bridge of the diseased bridge to meet the foundation bearing capacity requirements of T-beam side assembly and beam moving operation; when the position of concrete foundation 1-3 is wrongly matched with the existing bridge cap , use bored piles to protect the existing bridge cap;

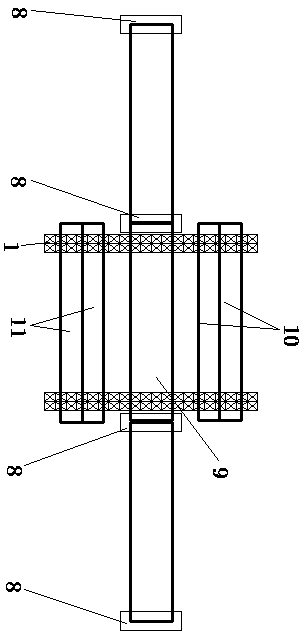

[0037] Step 2: After the construction of the concrete foundation 1-3 is completed, a pier steel tower 1 is erected according to the clear height requirements of the bridge with disease, and the pier steel tower 1 is erected in para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com