A kind of silver-iron-nickel electrical contact material and preparation method thereof

A technology of electric contact material, silver iron, applied in the direction of contacts, circuits, electric switches, etc., can solve the problem of large contact resistance, achieve low contact resistance, stable contact resistance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

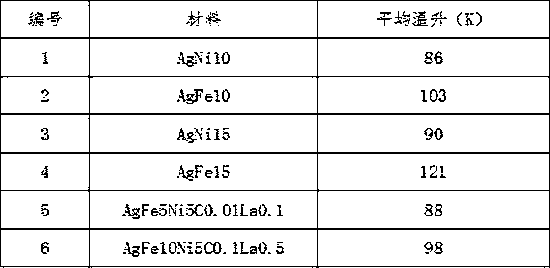

Examples

Embodiment 1

[0017] a) get 9.480kg silver powder, 0.250kg nickel powder and 0.250kg iron powder, sieve 200 orders;

[0018] b) silver-iron-nickel mixed powder mixed with 0.010kg of graphite powder and 0.010kg of lanthanum powder in a powder mixer for 6h;

[0019] c) The mixed powder obtained in step b is pressed into a spindle on a cold isostatic press, under a pressure of 100 MPa, and a holding time of 10 seconds;

[0020] d) The ingot obtained in step c was sintered at 800°C for 3 hours under the protection of hydrogen, and then extruded into a wire with a specification of Φ6mm;

[0021] e) The wire material obtained in step d is processed by cold drawing to make rivet contacts.

Embodiment 2

[0023] a) get 10.050kg silver powder, 4.000kg iron powder and 0.500kg nickel powder, and sieve 100 mesh;

[0024] b) silver-iron-nickel mixed powder mixed with 0.150kg of graphite powder and 0.300kg of lanthanum powder in a powder mixer for 8h;

[0025] c) The mixed powder obtained in step b is pressed into a spindle on a cold isostatic press with a pressure of 200 MPa and a holding time of 60 seconds;

[0026] d) The ingot obtained in step c is sintered at 850° C. for 2 hours under the protection of argon, and then extruded into a strip with a specification of 40×4 mm;

[0027] e) The strip obtained in step d is processed into a sheet contact through cold rolling-punching.

Embodiment 3

[0029] a) get 9.516kg silver powder and 2.400kg iron-nickel alloy powder, sieve 120 orders, wherein iron-nickel alloy composition is FeNi30;

[0030] b) silver-iron-nickel mixed powder mixed with 0.060kg of graphite powder and 0.024kg of lanthanum-nickel powder in a powder mixer for 4h, wherein the lanthanum-nickel alloy powder composition is LaNi5;

[0031] c) The mixed powder obtained in step b is pressed into a spindle on a cold isostatic press, under a pressure of 180MPa, and the holding time is 40S;

[0032] d) The ingot obtained in step c is sintered at 830°C for 4 hours under the protection of argon, and then extruded into a wire with a specification of Φ6mm;

[0033] e) The wire material obtained in step d is processed by cold drawing to make rivet contacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com