Soft package battery test probe

A soft package battery and test probe technology, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems that the probe is easy to damage the surface of the battery tab, the contact resistance is large, and it is inconvenient to be compatible. It achieves the effects of convenient type change, high contact resistance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

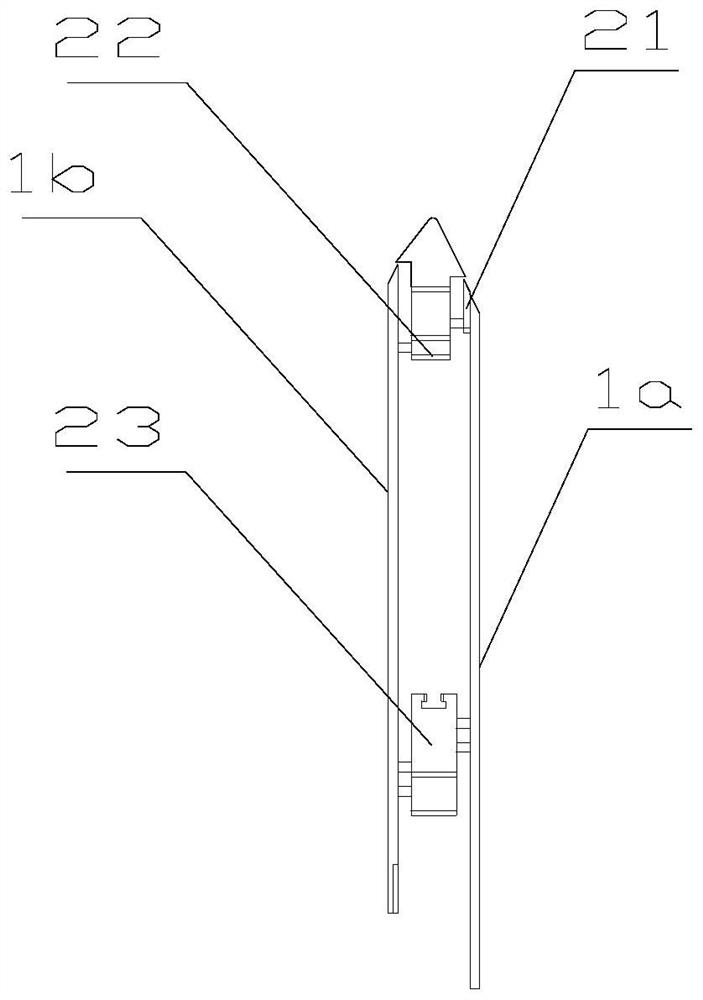

[0023] Embodiment 1 A test probe for a pouch battery according to the present invention includes a lug contact plate 1 for realizing circuit conduction between the battery and the test mechanism, a fixing unit 2 for fixing the probe, and a Magnet unit 3 clamping the lug, wherein:

[0024] The tab contact plate 1 is a conductive device, including a first guide plate body 1a and a second guide plate body 1b parallel to the first guide plate body, and the head and tail ends of the inner end surfaces of the first and second guide plate bodies Both have installation areas, and keep the installation areas of the two guide plates facing each other to form a gap for installing the fixing unit; the outer end surface of the first guide plate body is provided with a tab contact area for contacting and connecting with the tabs of the pouch battery 11. The tab contact area 11 is provided with a signal connection terminal, which is used to electrically connect with an external test device t...

Embodiment 2

[0034] Embodiment 2 The difference between this embodiment and Embodiment 1 is: from figure 1 It can be seen that the lug contact plate is the bottom layer, and the two ends of the lug contact plate are respectively fixed with the head mount of the printed board and the bottom slider of the printed board by screws; the inner surface of the printed board is installed with the magnet unit 3 .

[0035] From figure 2 and image 3 It can be seen that the mounting part on the head of the printed board has screw holes for fixing the tab contact plate; the slider at the bottom of the printed board has screw holes for fixing the tab contact plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com