A kind of processing method of cinnabar relief painting

A production method and cinnabar technology, applied in the field of art painting, can solve the problem of little research on coloring, and achieve the effect of maintaining long-term non-discoloration, reducing usage, and clear images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of processing and manufacturing method of cinnabar relief painting is carried out according to the following steps:

[0035] 1) Select the appropriate wood material according to the design draft, design requirements and production process requirements;

[0036] 2) Carry out rough carving and fine carving according to conventional methods to form a relief embryo body;

[0037] 3) Carry out detailed treatment on the embryo body, then polish it to make it smooth, and then apply anti-corrosion transparent primer for 1-2 times;

[0038] 4) Evenly spray or print the prepared basic color glue on the embryo body formed in step 3) to form the base color layer, spray after the color glue is dry, and repeat the operation 2-3 times;

[0039]5) After drying, use a tool to dip in cinnabar pigment to draw a coloring pattern on the outline of the embossed embossed body, dry it, and wax it to make a finished cinnabar embossed painting.

[0040] The basic color glue in the step ...

Embodiment 2

[0045] A kind of processing and manufacturing method of cinnabar relief painting is carried out according to the following steps:

[0046] With embodiment 1, wherein,

[0047] The basic color mortar in the step 4) is prepared according to the following method: first, the glue, alum and water are prepared in a weight ratio of 5:1:200 to make glue alum water, and then glue alum water and basic pigment powder are prepared in a weight ratio Become color glue, wherein the weight ratio of glue alum water and pigment is 1:0.5;

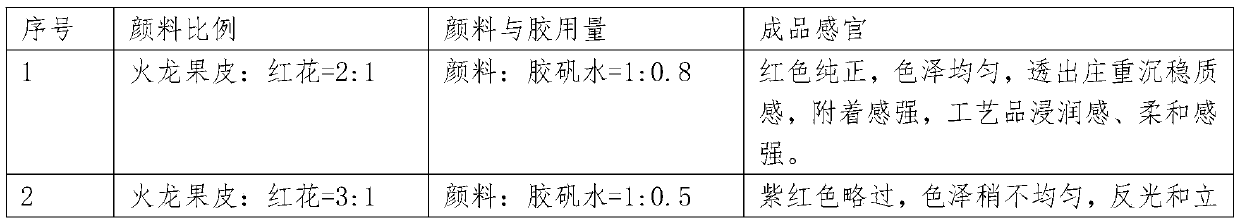

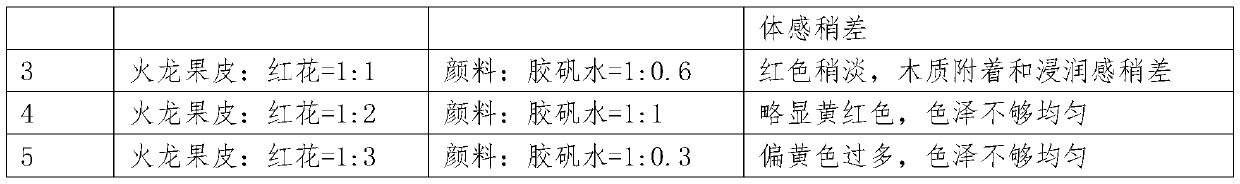

[0048] The basic pigment powder in the step 4) is obtained by drying the pitaya peel and safflower powder respectively and pulverizing them into a powder with a particle size of less than 0.2mm, and then mixing them according to the mass ratio of pitaya peel dry powder and safflower powder at 2:1.

[0049] The mass ratio of each composition in the cinnabar pigment in the step 5) is: cinnabar powder: kraft glue: gelatin: water=50:1:7:100, the preparation meth...

Embodiment 3

[0052] A kind of processing and manufacturing method of cinnabar relief painting is carried out according to the following steps:

[0053] With embodiment 1, wherein,

[0054] The basic color mortar in the step 4) is prepared according to the following method: first, the glue, alum and water are prepared in a weight ratio of 6:1:200 to make glue alum water, and then glue alum water and basic pigment powder are prepared in a weight ratio Become color glue, wherein the weight ratio of glue alum water and pigment is 1:0.6;

[0055] The basic pigment powder in the step 4) is obtained by drying the pitaya peel and safflower powder respectively and pulverizing them into a powder with a particle size of less than 0.2mm, and then mixing them according to the mass ratio of pitaya peel dry powder and safflower powder at 2:1.

[0056] The mass ratio of each composition in the cinnabar pigment in the step 5) is: cinnabar powder: kraft glue: gelatin: water=45:2:5:100, the preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com