Wet chemical treatment method for heterojunction battery

A technology of wet chemical treatment and heterojunction cells, which is applied in the field of solar cells, can solve the problems of increasing investment in factory equipment and facilities, increasing production costs, and many process steps, so as to reduce steps and complexity, use less, and process The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

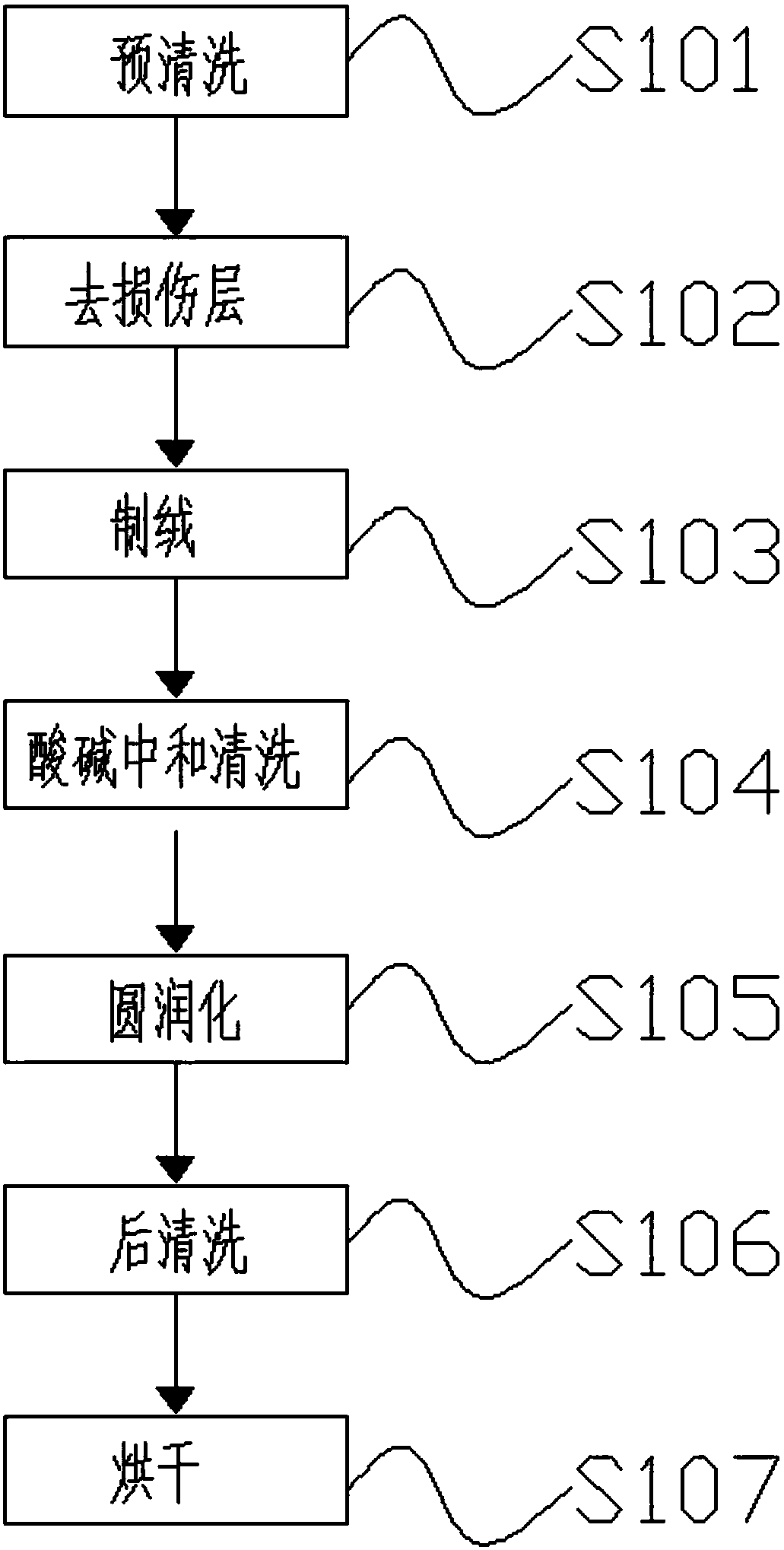

[0018] Such as figure 1 A wet chemical treatment method for a heterojunction battery is shown, the treatment method includes the following steps:

[0019] Step S101, the silicon wafer is pre-cleaned, and the silicon wafer is placed in potassium hydroxide with an ozone concentration of 5-35ppm and a mass percentage of 0.01%-0.5%, and the pre-cleaning is performed at a temperature of 30-50°C for 2-10 minutes ;

[0020] Step S102, performing damage removal treatment on the pre-cleaned silicon wafer, putting the silicon wafer into a potassium hydroxide solution with a mass percentage of 3%-20% and a deionized water mass percentage of 80%-97%, and the reaction temperature is Treat at 70°C-90°C for 1-5 minutes to remove the mechanical damage layer on the surface, and the etching depth of the silicon wafer is 5-20um. ;

[0021] Step S103, performing texturing on the silicon wafer after the damage removal treatment, putting the silicon wafer into a potassium hydroxide solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com