Method for rapidly determining content of 3-chloro-1,2-propylene glycol in PAE resin solution

A resin solution, rapid measurement technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of errors, complex time-consuming, etc., to avoid errors, improve work efficiency, and respond quickly and thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

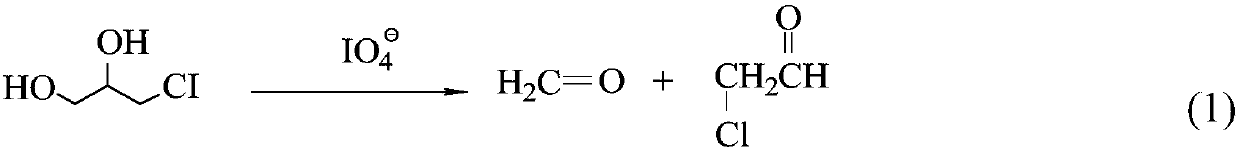

Method used

Image

Examples

Embodiment

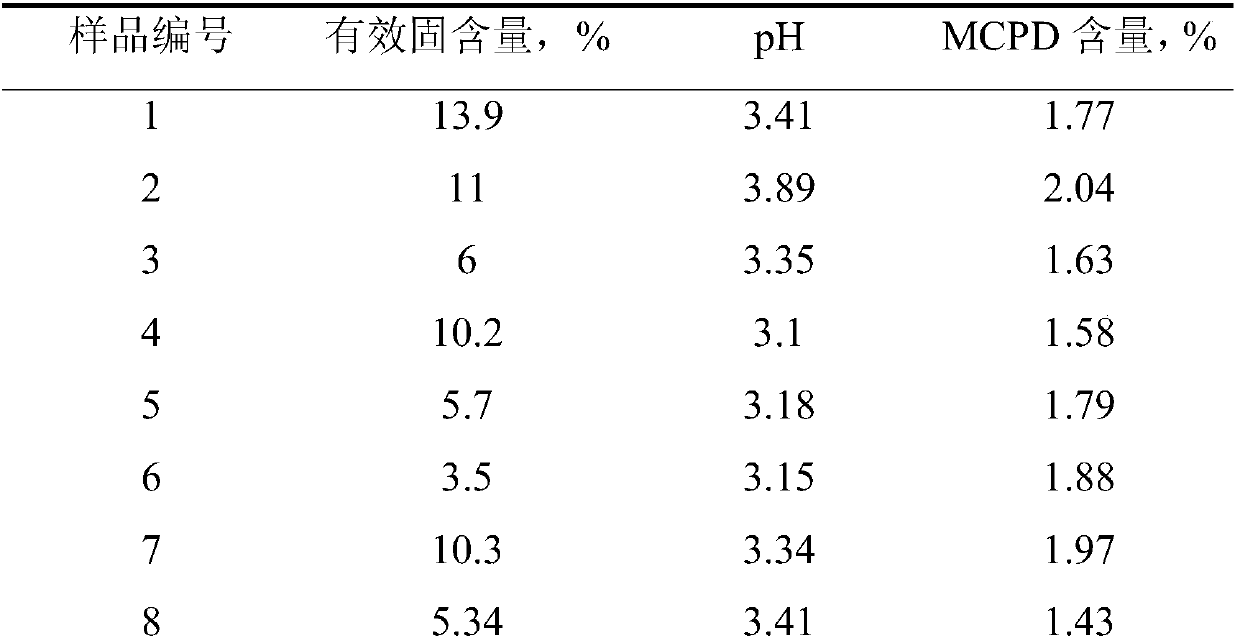

[0027] The present embodiment measures the MCPD content of 10 kinds of commercially available PAE resins:

[0028] (1) Sample preparation: After diluting the PAE resin sample solution 8 times, pipette 1mL into the headspace bottle accurately with a pipette gun, and then add high iodine with a concentration of 0.04mol / L and a volume of 2mL into the headspace bottle After sodium hydroxide solution, cap the headspace vial immediately, oxidize it at room temperature in the dark for 10 minutes, and inject boron with a concentration of 5 g / L (in 2 mol / L sodium hydroxide solution) and a volume of 0.8 mL with a syringe. Sodium hydride solution is enough; the PAE resin sample without redox treatment is used as blank;

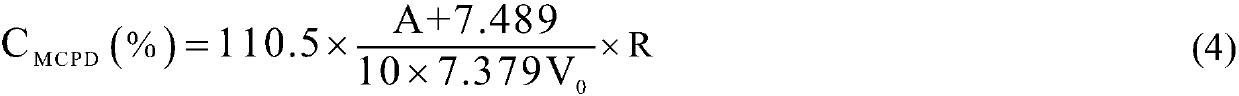

[0029] (2) Establish a standard curve: Dilute the known formaldehyde standard sample after calibration into a series of solutions with a concentration gradient (1-10mmol / L), and after the redox in step (1), set the headspace sampler and gas phase The operating condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com