Preparation method and application of graphene oxide array color-changing film/composite film

A graphene array and color-changing film technology, applied in the field of chemical materials, can solve the problems of poor repeatability, uneven size, and disorder of optical properties of materials, and achieve fast, accurate and visual detection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of graphene oxide array color-changing film comprises the following steps:

[0059] (1) The synthetic method of graphene oxide is as follows:

[0060] Into a 250 mL round bottom flask was added the obtained pre-oxidized graphene product and 20 mL of H 2 SO 4 , slowly add 2.5g KMnO in ice-water bath at 0℃ 4 . The reaction was carried out at 35°C for 2 hours. Slowly add 116.5mL of deionized water dropwise, and after 2 hours of reaction, add dropwise 3.3mL of H 2 o 2 (30%), the solution turned bright yellow. Wash with 1M HCl and deionized water until the pH of the solution reaches 6 to obtain a graphene oxide aqueous solution, and centrifuge and sonicate to obtain graphene oxide.

[0061] (2) Disperse the graphene oxide prepared by the above method into water and prepare solutions of different concentrations: [c]=3mg / mL, 4mg / mL, 5mg / mL, 6mg / mL; obtain different concentrations of graphite oxide Alkene solution;

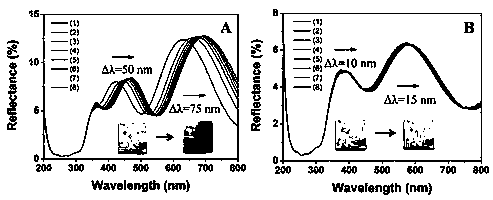

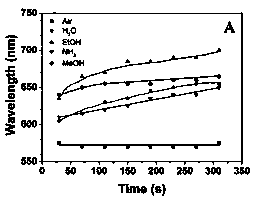

[0062] From attached figure ...

Embodiment 2

[0068] On the basis of the film obtained in Example 1, the graphene oxide solution with a concentration of 3 mg / mL was again spin-coated to obtain a graphene oxide film, and so repeatedly spin-coated to obtain an array of graphene oxide films, and the spin-coating conditions were the same as in the embodiment 1.

Embodiment 3

[0070] To obtain the preparation of graphene oxide composite film, graphene oxide is combined with PDDA solution to prepare graphene oxide array color-changing composite film, and its specific steps are as follows:

[0071] (1) adopt improved Hummers method to prepare graphene oxide (with embodiment 1, below if no special instructions, all adopt the Hummers method of embodiment 1 to prepare graphene oxide);

[0072] (2) prepare graphene oxide solution;

[0073] (3) To modify the silicon wafer substrate, mix concentrated sulfuric acid with a mass concentration of 98% and hydrogen peroxide with a mass concentration of 30% according to a volume ratio of 7:3 to prepare a solution A. Soak the silicon wafer in solution A and treat it at 90°C for 1.5 hours. Wash the hydrophilically treated silicon wafers with deionized water and dry them for later use.

[0074] (4) Preparation of polymer solution:

[0075] Preparation of PDDA solution: Take 0.75mL PDDA (20wt%), add 100mL deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com