Mute dustproof sealed chain

A dust-proof sealing and chain technology, which is applied in chain rings, transmission chains, etc., can solve the problems of increased manufacturing costs, low production efficiency, and large investment, so as to prevent the intrusion of abrasive media, ensure the lubrication effect, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

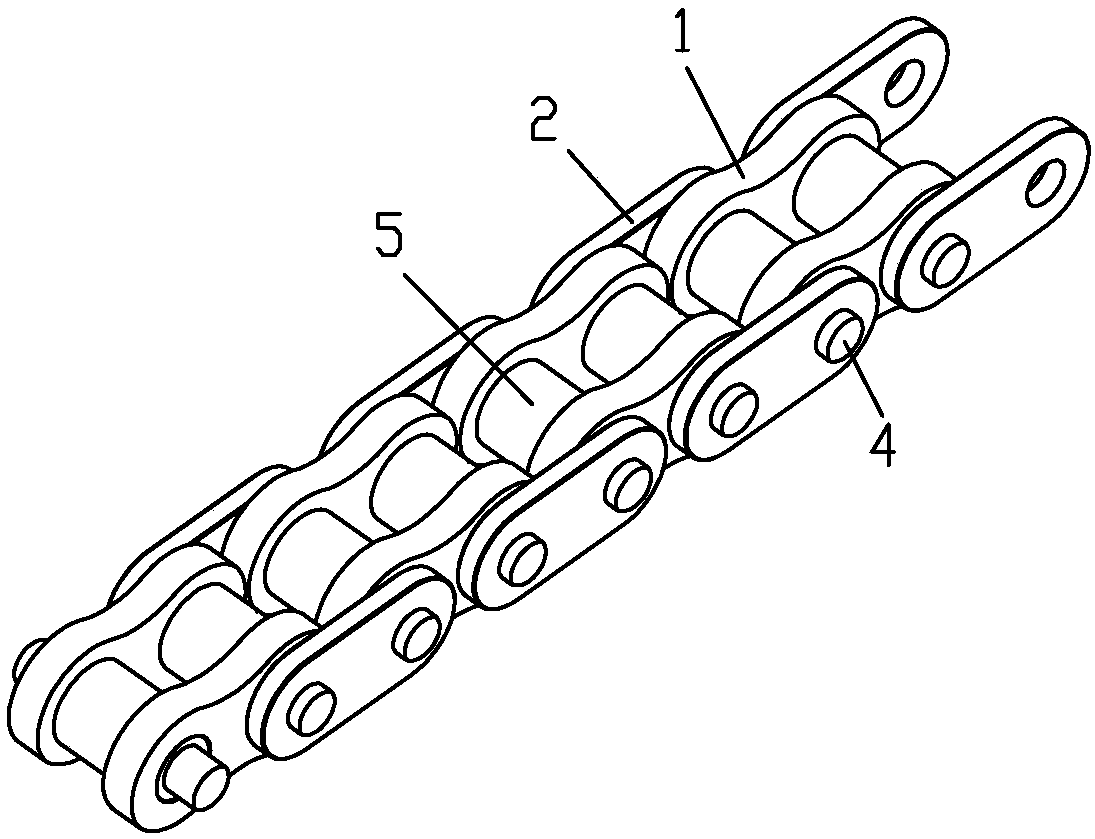

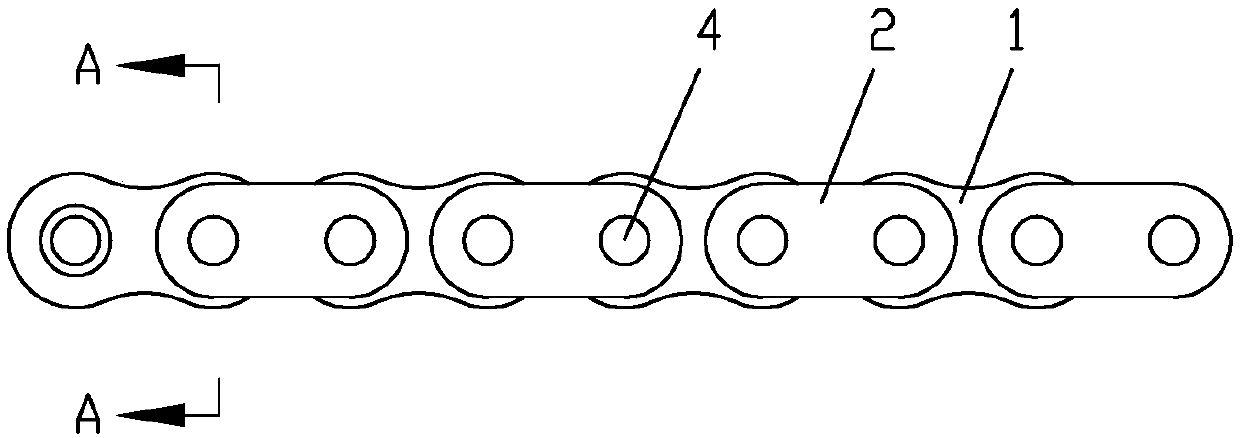

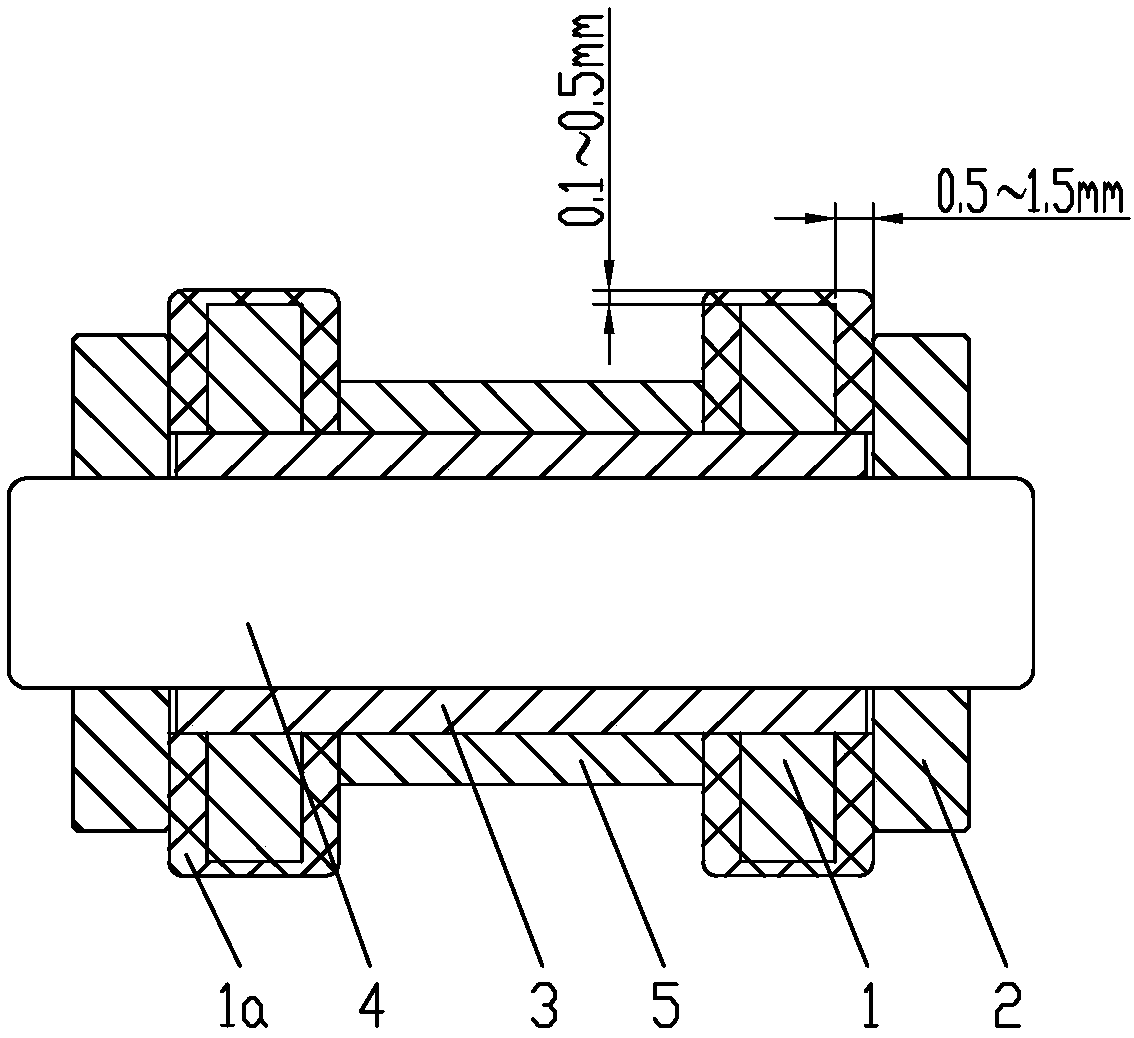

[0017] see figure 1 , figure 2 , image 3 , a silent and dust-proof sealed chain, including an inner chain plate 1, an outer chain plate 2, a sleeve 3, a pin shaft 4 and a roller 5, the inner chain plate 1 is formed to cover the entire outer surface of the chain plate body, and the hardness is low Covering layer 1a on the inner chain plate body; the covering layer 1a is formed on the inner chain plate body by injection molding, its thickness on the side of the chain plate body is 0.8mm, and the thickness on the edge face of the chain plate body is 0.15mm.

[0018] In this embodiment, the cover layer 1a can also be formed by injection molding of reinforced plastics, nylon, etc., and can also be attached to the surface of the inner chain plate body by rubber vulcanization; it can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com