A kind of four-layer butt-welded aluminum-plastic composite sp pipe and preparation method thereof

An aluminum-plastic composite and butt welding technology, applied in coatings, tubular items, other household appliances, etc., can solve the problems of poor protection of high-voltage lines, easy rebound, and time-consuming installation, and achieve the effect of protecting fast charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

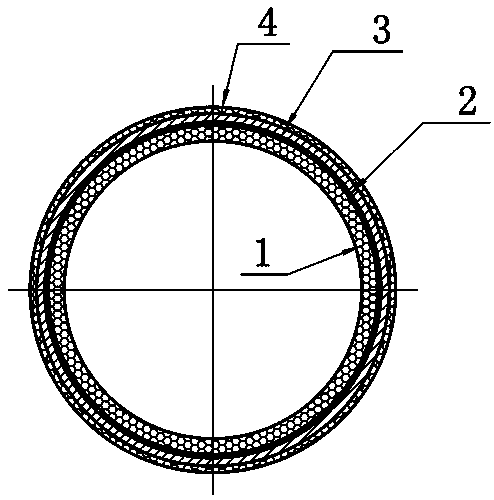

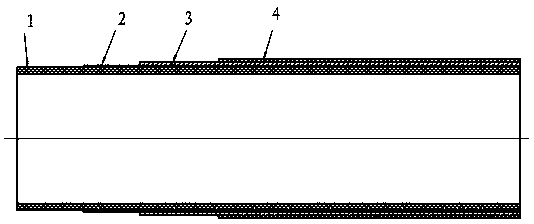

[0023] Such as Figure 1-2 As shown, a four-layer butt-welded aluminum-plastic composite SP pipe is provided with four layers in sequence from the inside to the outside, which are respectively the inner layer pipe 1, the glue layer 2, the middle layer pipe 3 and the outer layer pipe 4, the inner layer pipe and the outer layer pipe The layer pipes are all made of polyethylene PEX material, and the middle layer pipe is made of high-strength alloy aluminum strip.

[0024] In this embodiment, the specific material of the high-strength alloy aluminum strip is A5052 alloy.

[0025] The preparation method of the above-mentioned four-layer butt-welded aluminum-plastic composite SP pipe comprises the following steps:

[0026] 1) Extrusion of the inner layer tube: the stirred raw materials are sucked into the storage barrel through the automatic sucti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap