Environment-friendly anti-fouling material based on silicone hydrogel resin and natural anti-fouling agent

A technology of silicone hydrogel and natural antifouling agent, which is applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., and can solve the problem of limiting the development of hydrogel antifouling coatings and coating surfaces Poor adhesion, poor mechanical properties and other problems, to achieve the effect of improving adhesion and weather resistance, strong adhesion, and lasting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

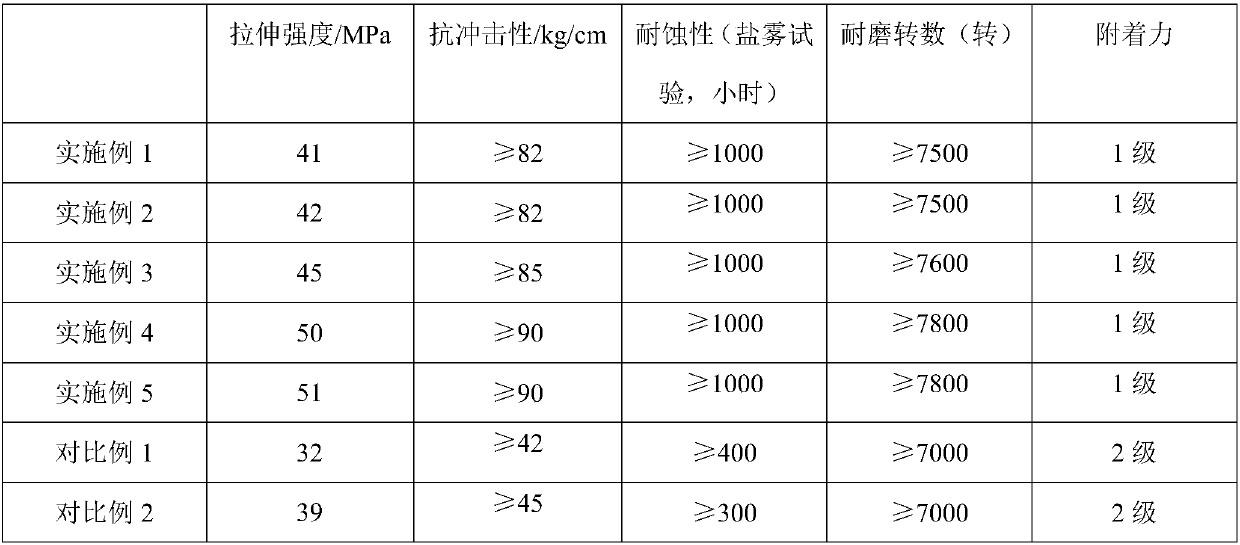

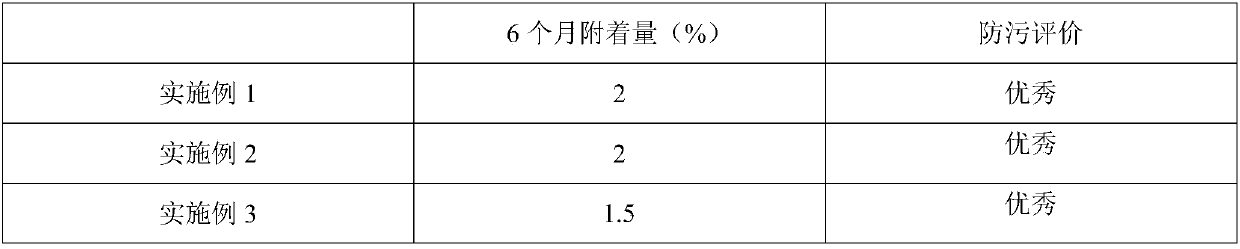

Examples

Embodiment 1

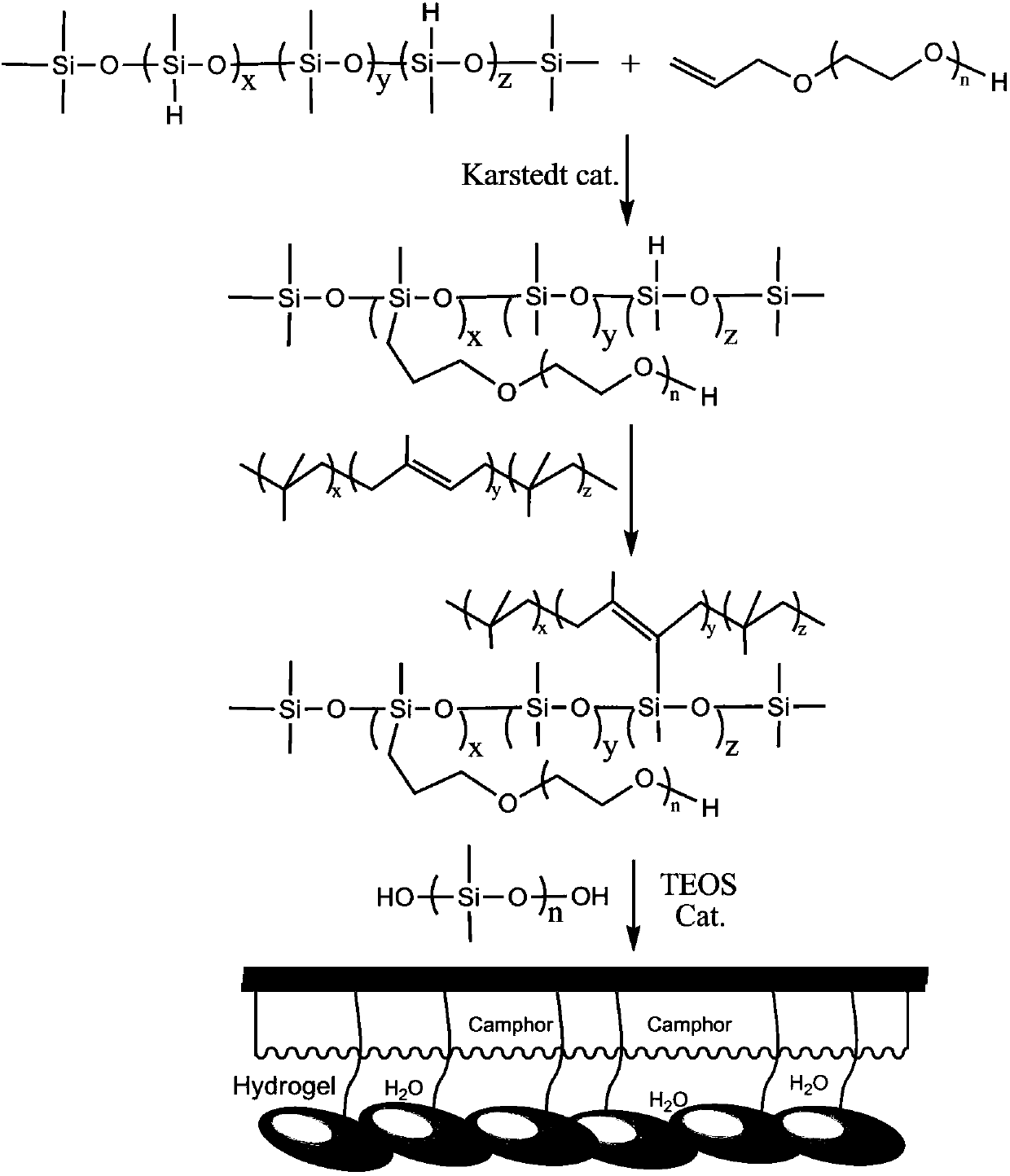

[0034] The preparation route of embodiment 1 and embodiment 3~5 is as follows:

[0035]

[0036] Wherein, x, y, z and n are all integers ≥ 1.

[0037] Example 1:

[0038] The preparation method of the environment-friendly antifouling material based on silicone hydrogel resin and natural antifouling agent, comprises the following steps:

[0039] (1) Using allyl polyglycol ether and hydrogen-containing silicone oil as starting materials, heat to 70°C for hydrosilation reaction, then add fully swollen and dissolved butyl rubber in xylene, and continue the reaction for 50 minutes to prepare into silicone hydrogel resin;

[0040] (2) Keeping the reaction temperature constant, add thixotropic agent, hydroxyl silicone oil, 3-hydroxybutenoic acid-β-lactone, 4,5-dichloro-2 to the silicone hydrogel resin obtained in step (1) -n-octyl-4-isothiazolin-3-one, synthetic camphor and cage polysilsesquioxane, stirred and reacted for 1 hour to obtain component A, set aside;

[0041] (3) M...

Embodiment 2

[0054] The preparation method of the environment-friendly antifouling material based on silicone hydrogel resin and natural antifouling agent, comprises the following steps:

[0055] (1) Using ethylene glycol monoallyl ether and hydrogen-containing silicone oil as starting materials, heating to 90°C for hydrosilation reaction, then adding fully swollen and dissolved butyl rubber in xylene, and continuing the reaction for 70 minutes to prepare into silicone hydrogel resin;

[0056] (2) Keeping the reaction temperature constant, add thixotropic agent, hydroxyl silicone oil, 3-hydroxybutenoic acid-β-lactone, 4,5-dichloro-2 to the silicone hydrogel resin obtained in step (1) - n-octyl-4-isothiazolin-3-one, synthetic camphor and cage polysilsesquioxane, stirred and reacted for 2 hours to obtain component A, set aside;

[0057] (3) Mix ethyl orthosilicate with di-n-butyltin dilaurate, methyltriethoxysilane, cyclohexanone, acetylacetone and xylene to obtain component B;

[0058] (4...

Embodiment 3

[0071] The preparation method of the environment-friendly antifouling material based on silicone hydrogel resin and natural antifouling agent, comprises the following steps:

[0072] (1) Using allyl polyglycol ether and hydrogen-containing silicone oil as starting materials, heat to 80°C for hydrosilation reaction, then add fully swollen and dissolved butyl rubber in xylene, and continue the reaction for 60 minutes to prepare into silicone hydrogel resin;

[0073] (2) Keeping the reaction temperature constant, add thixotropic agent, hydroxyl silicone oil, 3-hydroxybutenoic acid-β-lactone, 4,5-dichloro-2 to the silicone hydrogel resin obtained in step (1) -n-octyl-4-isothiazolin-3-one, synthetic camphor and cage polysilsesquioxane, stirred and reacted for 1 hour to obtain component A, set aside;

[0074] (3) Mix ethyl orthosilicate with di-n-butyltin dilaurate, methyltriethoxysilane, cyclohexanone, acetylacetone and xylene to obtain component B;

[0075] (4) Mix component A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com