Superhydrophobic powder coating, and preparation method and application thereof

A powder coating and super-hydrophobic technology, which is applied in the field of material chemistry, can solve problems such as inability to guarantee hydrophobic effect and poor wear resistance, and achieve excellent durability, prevent pollution, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

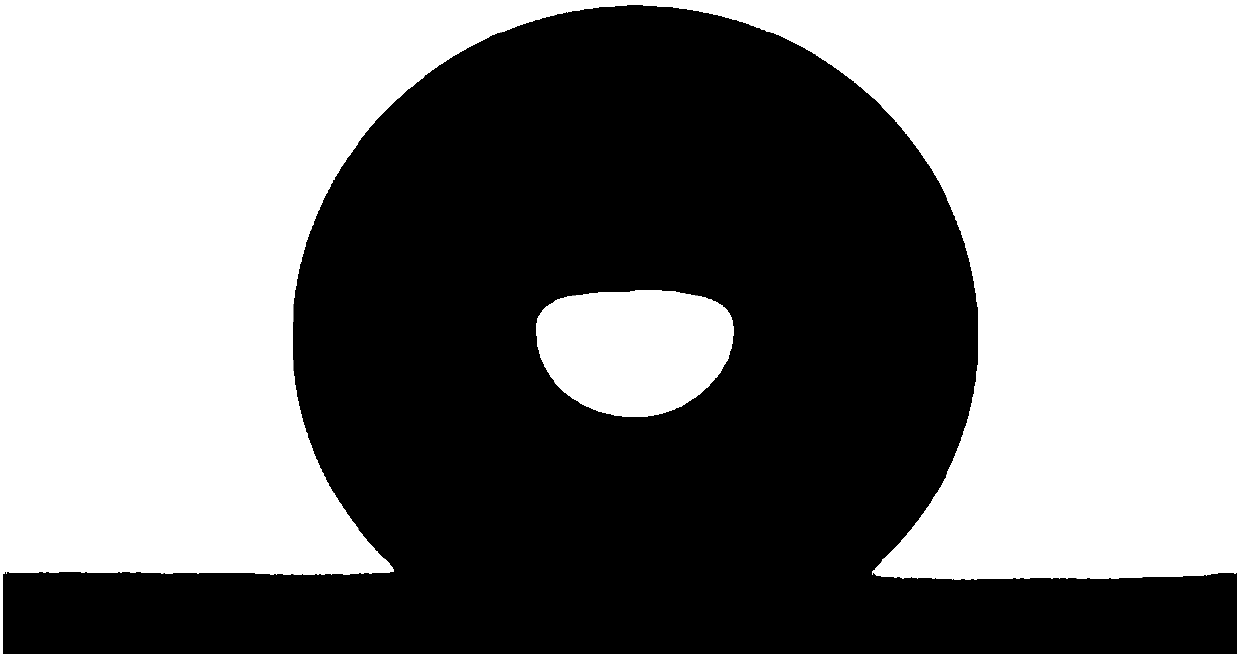

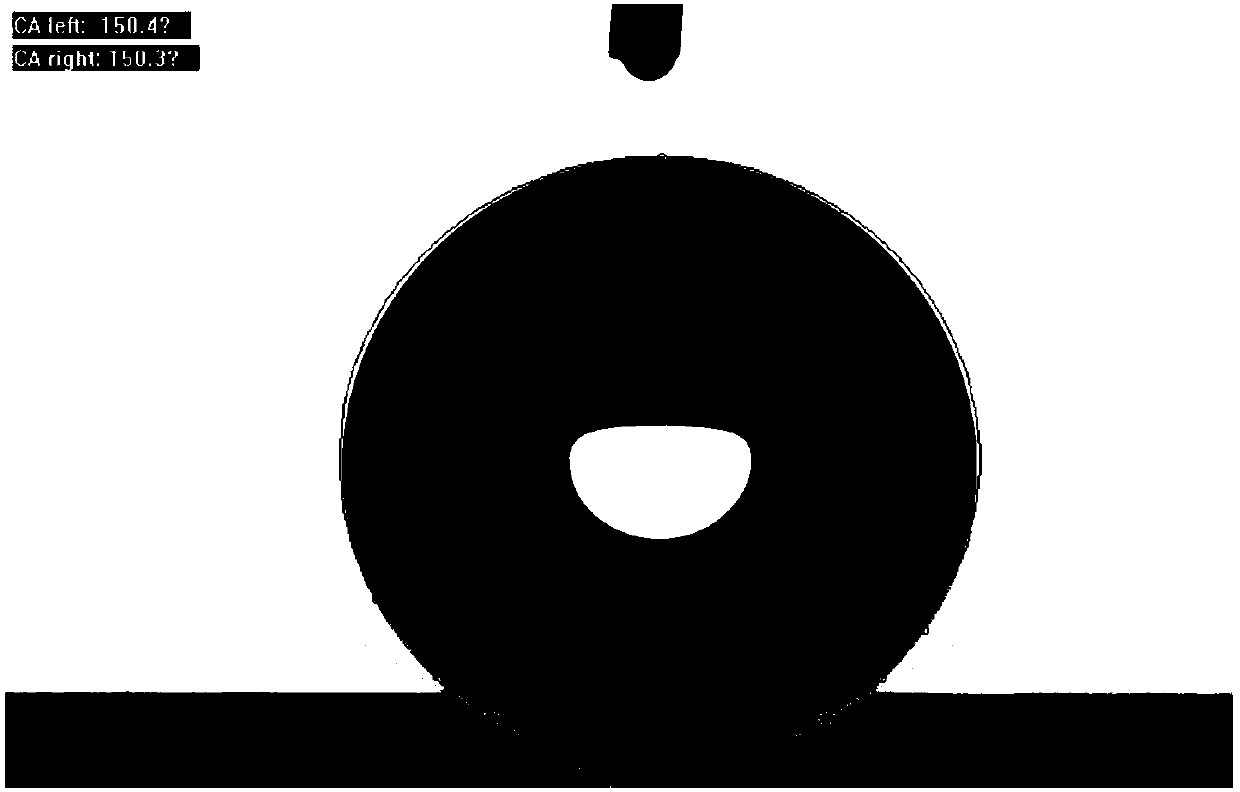

[0035] (1) Preparation of hydrophobically modified powder: use silica sol silica powder modified by fluorosilane and TEOS as hydrophobically modified powder, use absolute ethanol as solvent, add ammonia water and deionized water, then add dropwise aqueous silica sol, When stirring, add fluorosilane and TEOS dropwise, stir for 24 hours, dry and grind into powder, the particle size of powder is 10-50 μm;

[0036] (2) Hydrophobic modified powder and resin powder blending: the resin adopts solid powdered PTFE resin, and the mesh number is 250 mesh. After the resin powder is heated to the melting point to make it melt, according to "hydrophobic modified powder: resin = 1: 4” mass ratio, add hydrophobic powder and continue to stir, melt and extrude, and dry in an oven at 80°C, press the dried product into tablets, crush it, and finally grind it into powder with a particle size of 10-50 μm, disperse in butyl acetate Add 3-4 drops of fluorosilane dropwise to the solution, and place it...

Embodiment 2

[0043](1) Preparation of hydrophobically modified powder: use silica sol silica powder modified by fluorosilane and TEOS as hydrophobically modified powder, use absolute ethanol as solvent, add ammonia water and deionized water, then add dropwise aqueous silica sol, When stirring, add fluorosilane and TEOS dropwise, stir for 24 hours, dry and grind into powder, the particle size of powder is 10-50 μm;

[0044] (2) Hydrophobic modified powder and resin powder blending: the resin adopts solid powdered thermoplastic polyurethane resin, and the number of mesh is 800 mesh. : 1” mass ratio, add hydrophobic powder and continue to stir, melt and extrude, and dry in an oven at 80°C, press the dry matter, crush it, and finally grind it into powder with a particle size of 10-50 μm, disperse in butyl acetate In the ester solution, add 3-4 drops of fluorosilane dropwise, and place it in an ultrasonic instrument for 5-10 minutes;

[0045] (3) Prepare a superhydrophobic coating on the surfa...

Embodiment 3

[0052] (1) Preparation of hydrophobically modified powder: use silica sol silica powder modified by fluorosilane and TEOS as hydrophobically modified powder, use absolute ethanol as solvent, add ammonia water and deionized water, then add dropwise aqueous silica sol, When stirring, add fluorosilane and TEOS dropwise, stir for 24 hours, dry and grind into powder, the particle size of powder is 10-50 μm;

[0053] (2) Blending of hydrophobic modified powder and resin powder: the resin is a polyester resin in the form of a solid powder with a mesh number of 500 mesh. After the resin powder is heated to the melting point to melt it, follow the "hydrophobic modified powder: Resin = 2:1" mass ratio, add hydrophobic powder and continue to stir, melt and extrude, and dry in an oven at 80°C, press the dried product into tablets, crush it, and finally grind it into powder with a particle size of 10-50 μm, disperse Add 3-4 drops of fluorosilane dropwise to the butyl acetate solution, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com