Modified plastic for laser welding and preparation method thereof

A laser welding and modification technology, applied in the field of materials, can solve the problems of low laser transmittance, strong toxicity and high mobility, and achieve the effects of high laser transmittance, good weather resistance and low mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

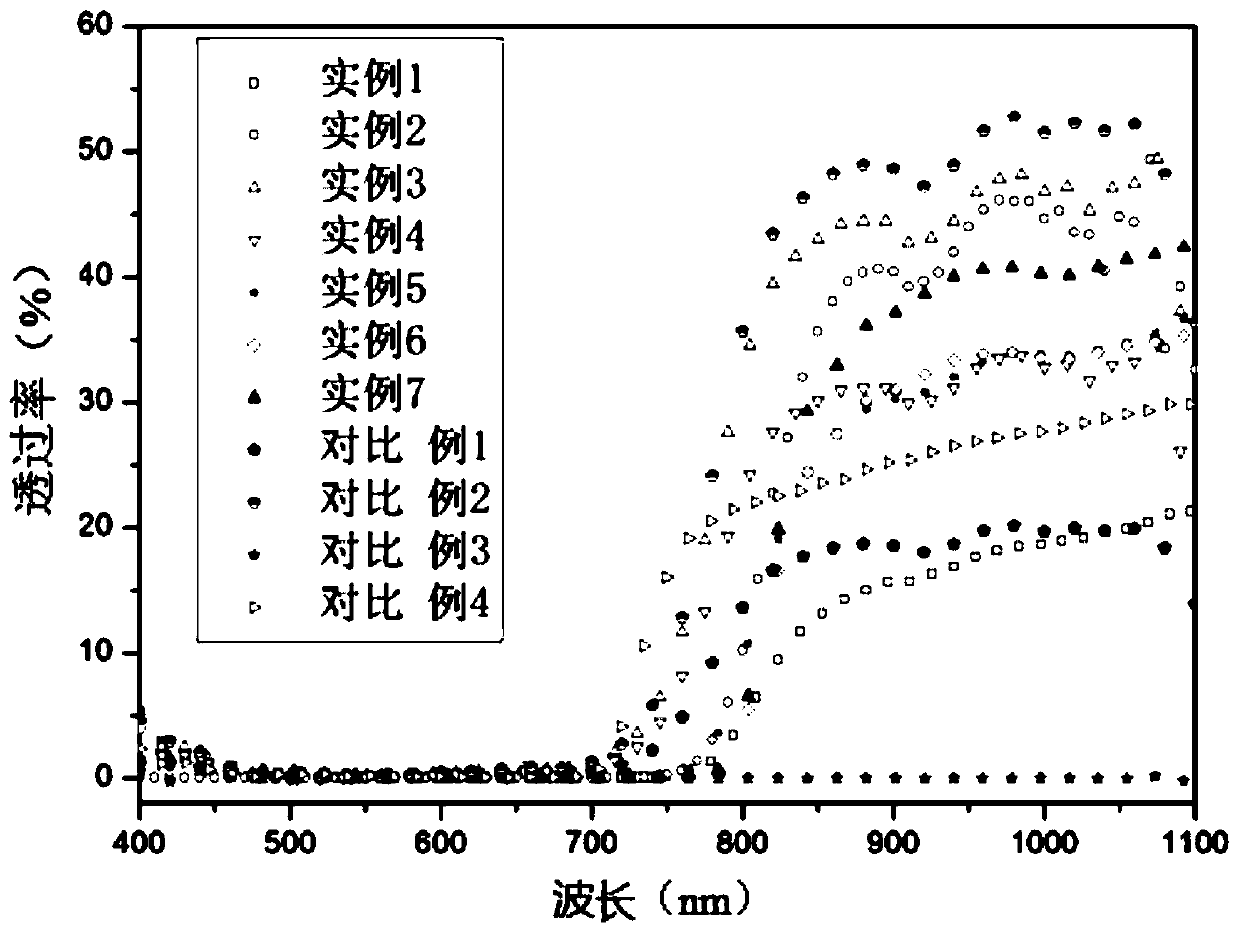

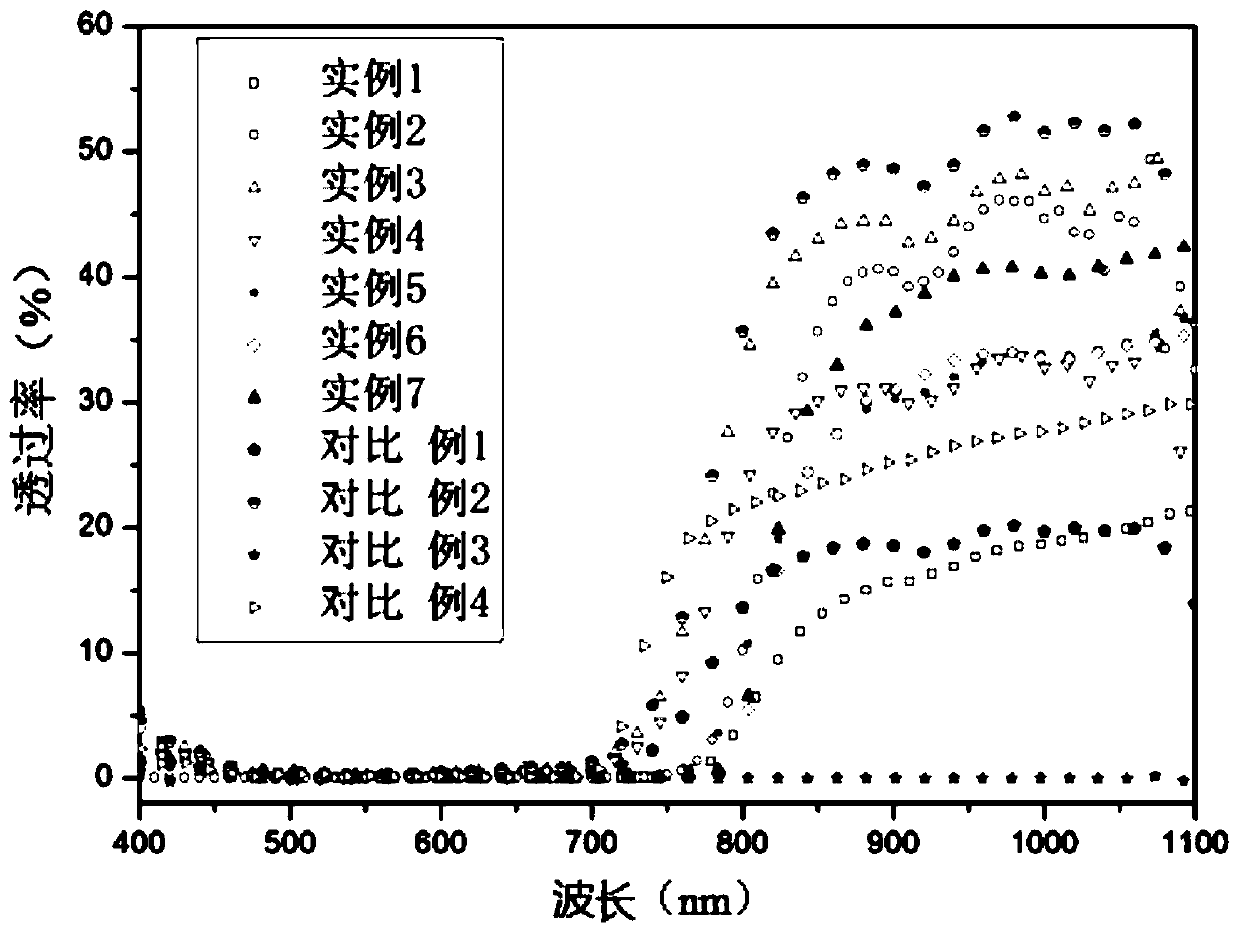

Image

Examples

Embodiment 1

[0034] With 84kg polypropylene H9018, 15kg ethylene-octene copolymer 8137, 0.2kg perylene-based black toner L480, 0.3kg antioxidant 1010, 0.2kg lubricant (stearic acid), 0.3kg weather resistance additive, in the long Melt, mix and disperse in a twin-screw extruder with a diameter ratio of 40:1, extrude at a temperature of 200°C, extrude and granulate, and finally obtain the product.

Embodiment 2

[0036] 54kg polypropylene K9017, 27kg polypropylene BX3900, 18kg ethylene-butene copolymer 7467, 0.2kg perylene-based black toner L480, 0.3kg antioxidant 1010, 0.2kg lubricant (stearic acid), 0.3kg weather resistance The auxiliary agent is melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, and the extrusion temperature is 200° C., extruded and granulated, and finally the product is obtained.

[0037] Example 2 On the basis of Example 1, a single type of polypropylene is replaced by two types of polypropylene mixtures, these two types of polypropylene are respectively homopolymerized and copolymerized with different melt fingers, and the two components The combination ensures that the substrate has higher laser transparency than that of Example 1 on the basis that the material has a certain processing type and mechanical properties. After adding the same content of perylene-based black toner, its laser transparency Transient still has ...

Embodiment 3

[0039] 50kg polypropylene K9017, 30kg polypropylene BX3900, 19kg ethylene-butene copolymer 7467, 0.05kg perylene-based black toner L480, 0.3kg antioxidant 1010, 0.3kg lubricant (stearic acid), 0.35kg weather resistance The auxiliary agent is melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, and the extrusion temperature is 200° C., extruded and granulated, and finally the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com