Recycled brick aggregate concrete and preparation method thereof

A technology for reclaiming bricks and concrete, applied in the field of building materials, can solve the problems of insufficient performance of thermal insulation of brick-aggregate concrete, and achieve the effects of excellent thermal insulation performance, high strength, and reduced water-to-binder ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

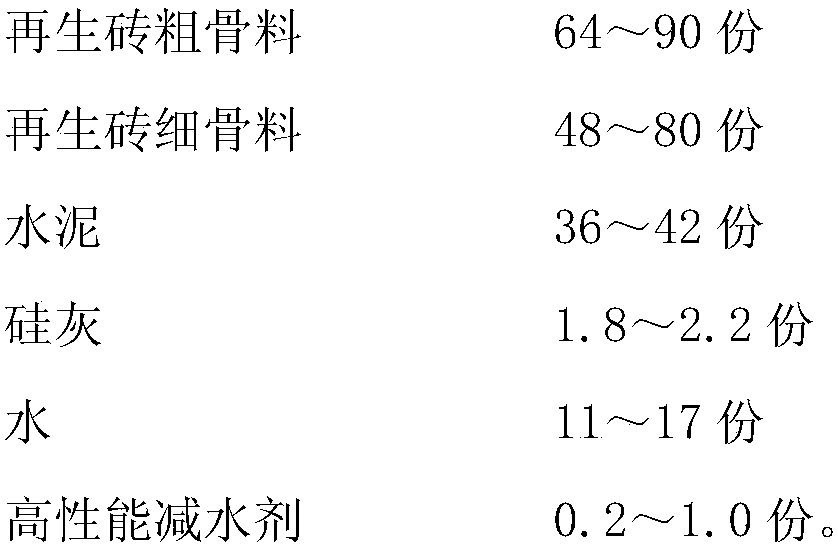

[0031] A recycled brick aggregate concrete. The ratio of recycled brick aggregate concrete by mass includes:

[0032]

[0033] The preparation process of the recycled brick aggregate concrete is as follows:

[0034] Pre-wet the coarse aggregate of recycled bricks and the fine aggregate of recycled bricks respectively for 24h in advance, and then put them in a mixer and mix them for 30s at a rate of 30r / min. Then mix the cement and silica fume in advance and add them to the forced mixer. Continue mixing for 30s, and finally add water and polycarboxylic acid high-performance water reducing agent into the mixer at the same time and mix for 3 minutes to obtain recycled brick aggregate concrete.

example 2

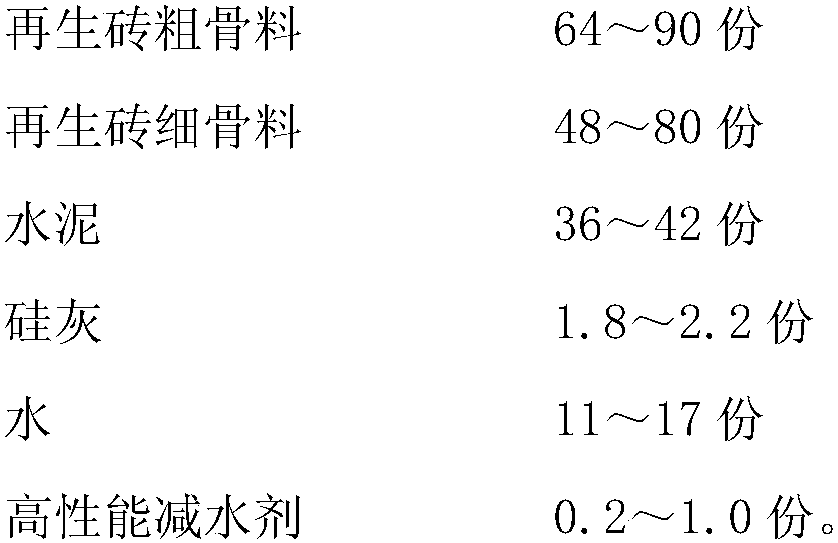

[0036] A recycled brick aggregate concrete. The ratio of recycled brick aggregate concrete by mass includes:

[0037]

[0038] The preparation process of the recycled brick aggregate concrete is as follows:

[0039] Pre-wet the coarse aggregate of recycled bricks and the fine aggregate of recycled bricks for 20 hours in advance, and then put them in a mixer, and mix them for 20 seconds at a rate of 40r / min. Then, mix the cement and silica fume in advance and add them to the mixer to continue. Mix for 20s, and finally add water and polycarboxylic acid-based high-performance water reducing agent into the mixer at the same time and mix for 2 minutes to obtain recycled brick aggregate concrete.

example 3

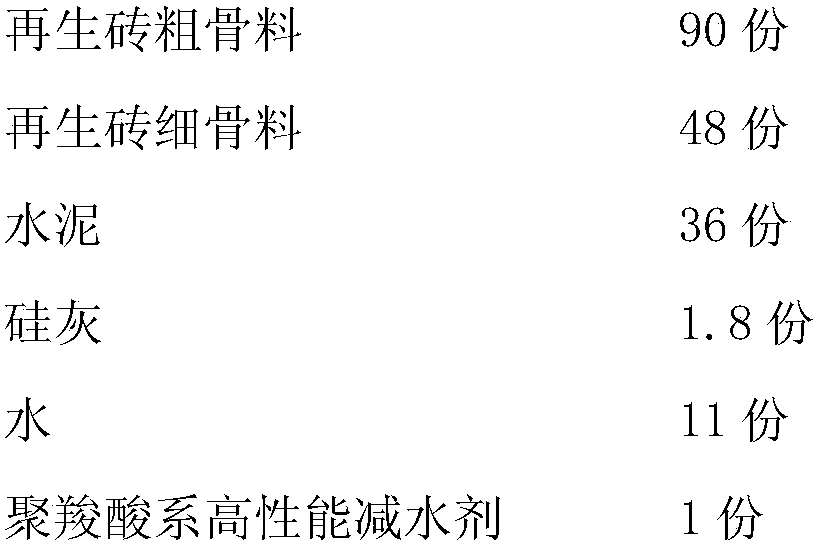

[0041] A recycled brick aggregate concrete. The ratio of recycled brick aggregate concrete by mass includes:

[0042]

[0043]

[0044] The preparation process of the recycled brick aggregate concrete is as follows:

[0045] Pre-wet the coarse aggregate of recycled bricks and the fine aggregate of recycled bricks for 30 hours in advance, and then put them in a mixer and mix them for 60 seconds at a rate of 20r / min. Then, mix the cement and silica fume in advance and add them to the mixer to continue. Mix for 60 seconds, and finally add water and polycarboxylate high-performance water reducing agent into the mixer at the same time and mix for 5 minutes to obtain recycled brick aggregate concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com