Anti-scaling method for treatment process of sewage containing high-concentration molybdenum and zirconium elements

A sewage treatment, high-concentration technology, used in water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve problems such as equipment corrosion, long time required, and inability to remove scale layers, to prevent scale layer, easy operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

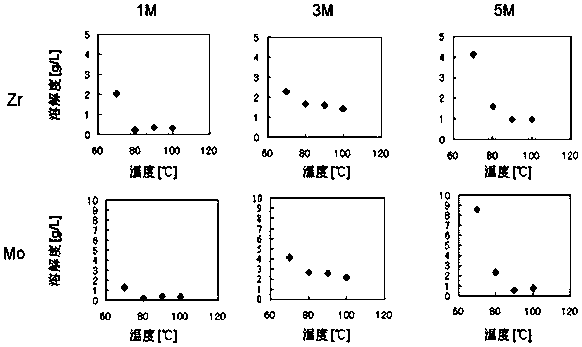

[0038] Under embodiment 1 investigation different temperatures, in different nitric acid solutions, the solubility change of zirconium molybdate

[0039] The precipitation of zirconium molybdate solid in solution is closely related to its solubility. Usually, the solubility of the substance will change under different temperature and acid concentration. In order to understand the precipitation mechanism of zirconium molybdate solids, it is very important to obtain the change curve of solubility under different conditions.

[0040] In the actual metal dissolution process, the concentration of nitric acid is 3mol / L. In the present invention, in order to obtain a more comprehensive solubility change curve, the concentration of nitric acid solution is set to 1, 3, 5mol / L. At the same time, set the temperature at four points of 70, 80, 90, and 100 (97) °C to obtain the solubility of zirconium molybdate in nitric acid solutions of various concentrations.

[0041] from figure 1 It...

Embodiment 2

[0042] Embodiment 2 analyzes the formation mechanism of zirconium molybdate scale layer

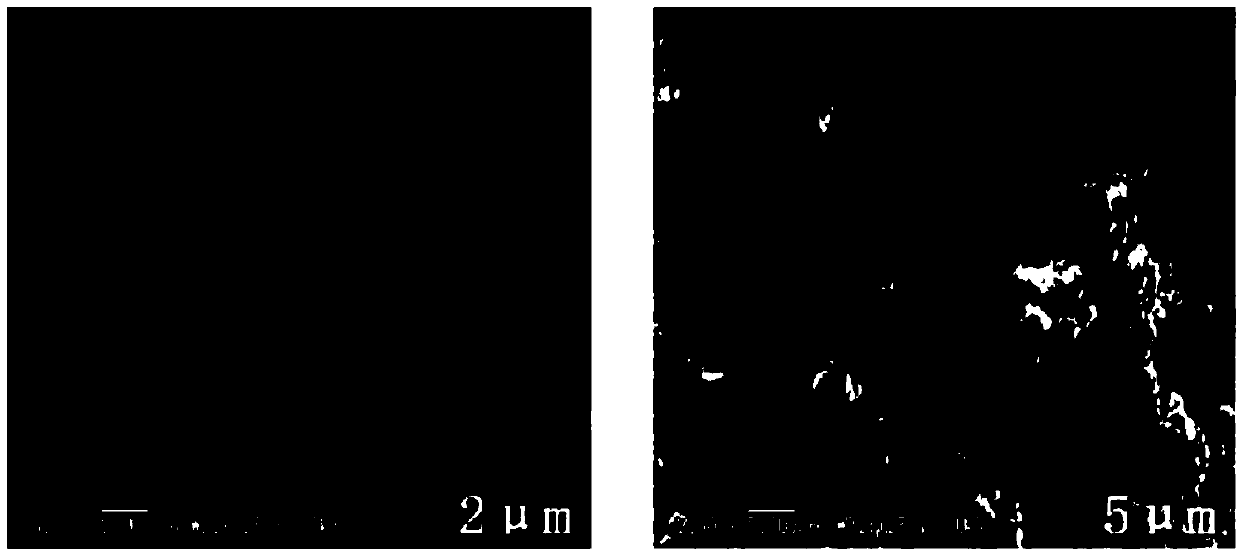

[0043] Peel off the solid zirconium molybdate attached to the inner wall of the container, and after vacuum drying, observe the surface morphology under a scanning electron microscope to analyze the precipitation and growth mechanism of zirconium molybdate.

[0044] from figure 2 It can be seen from the EM images that the scale layer is divided into two parts: dense layer and loose layer. The surface of the scale layer in contact with the container wall forms a dense layer with a uniform structure, and the surface in contact with the solution forms a loose layer with a heterogeneous structure where larger particles gather.

[0045] Since the heat conduction of the reaction vessel is carried out through the vessel wall to the interior of the solution, the temperature distribution in the reaction vessel gradually decreases from the outermost layer to the inside. The solubility of zirconi...

Embodiment 3

[0050] This embodiment provides an anti-scaling method in the process of sewage treatment containing high concentrations of molybdenum and zirconium elements. The technical solution is to add crystals to the sewage. The added crystal is zirconium molybdate.

[0051] The ratio of supersaturation to surface area of the added crystal is 0.236L / m 2 .

[0052] Of course, the above description is not intended to limit the present invention, and the present invention is not limited to the above examples. Any changes, modifications, additions or substitutions made by those skilled in the art within the scope of the present invention shall all belong to protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com