Low-polyfructose granulation device and application thereof

A fructo-oligosaccharide and granulation device technology, which is applied in the direction of powder suspension granulation, spray evaporation, evaporator accessories, etc., can solve the problem of short shelf life, affecting the application of fructo-oligosaccharide products, and restricting the expansion of fructo-oligosaccharide product application fields And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

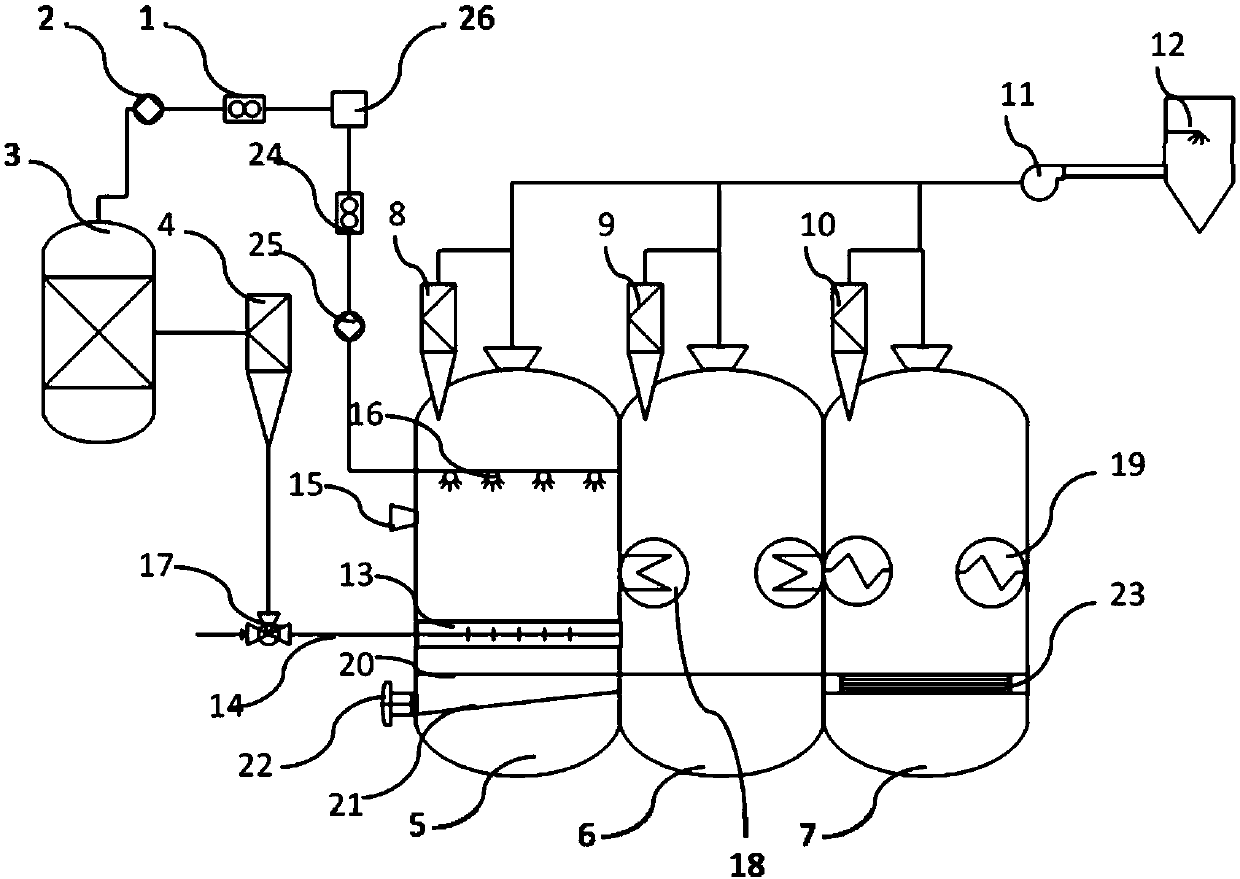

Embodiment 1

[0038] (1) Put the fructooligosaccharide syrup material into the diverting device, the content of fructooligosaccharide in the fructose oligosaccharide syrup is 95%, and the diverting device divides the fructooligosaccharide syrup into two paths, one of which passes through the flow meter I and the feeding pump I flows into the spray drying system, and the other flows into the slurry sprayer in the granulation fluidization chamber through flow meter II and feed pump II;

[0039] (2) the air inlet temperature of the spray dryer in the spray drying system is 200°C, the outlet air temperature is 50~80°C, the air inlet pressure is 2.5MPa, and the flow rate of the fructose oligosaccharide syrup is 1L / min;

[0040] (3) The flow rate of air in the mixer is 10L / min, the flow rate of fructooligosaccharide powder is 0.5kg / min, the spray flow rate of the slurry sprayer in the granulation fluidization chamber is 0.5kg / min, and the spray pressure is 1.5MPa , the slurry sprayer continuously...

Embodiment 2

[0042] Example 2: The effect of the spray flow rate of the slurry sprayer on the properties of fructooligosaccharide particles.

[0043] Other operations are the same as in Example 1, and the spray flow rate of adjusting the slurry sprayer is 0.1kg / min, 0.2kg / min, 0.3kg / min, 0.4kg / min, 0.5kg / min, and the compressive strength table of fructooligosaccharide particles is obtained 1 shown.

[0044] Table 1 The effect of the spray flow rate of the slurry sprayer on the properties of fructooligosaccharide particles

[0045] Spray flow

Embodiment 3

[0046] Example 3: The effect of the spray pressure of the slurry sprayer on the properties of fructooligosaccharide particles.

[0047] Other operations were the same as in Example 1, and the spray pressure of the slurry sprayer was adjusted to 1 MPa, 1.5 MPa, 2 MPa, 2.5 MPa, 3 MPa, and the compressive strength of fructooligosaccharide particles was obtained as shown in Table 1.

[0048] Table 2 The effect of spray pressure of slurry sprayer on the properties of fructooligosaccharide particles

[0049] Spray flow

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com