Semi-high door provided with idler wheel guide rail device

A technology of roller guide rails and half-height doors, applied in the field of half-height doors, to achieve the effect of improving service life and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

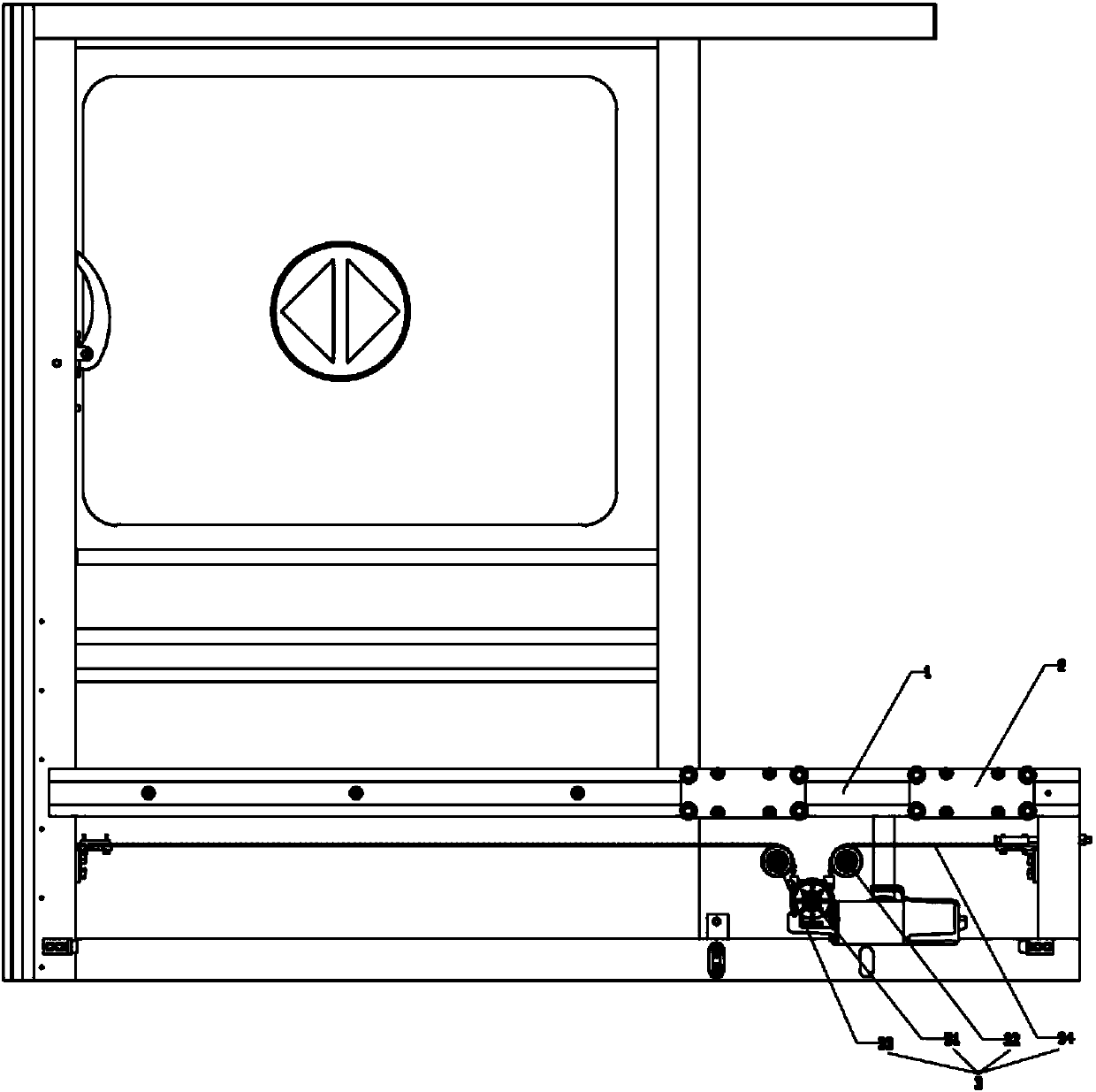

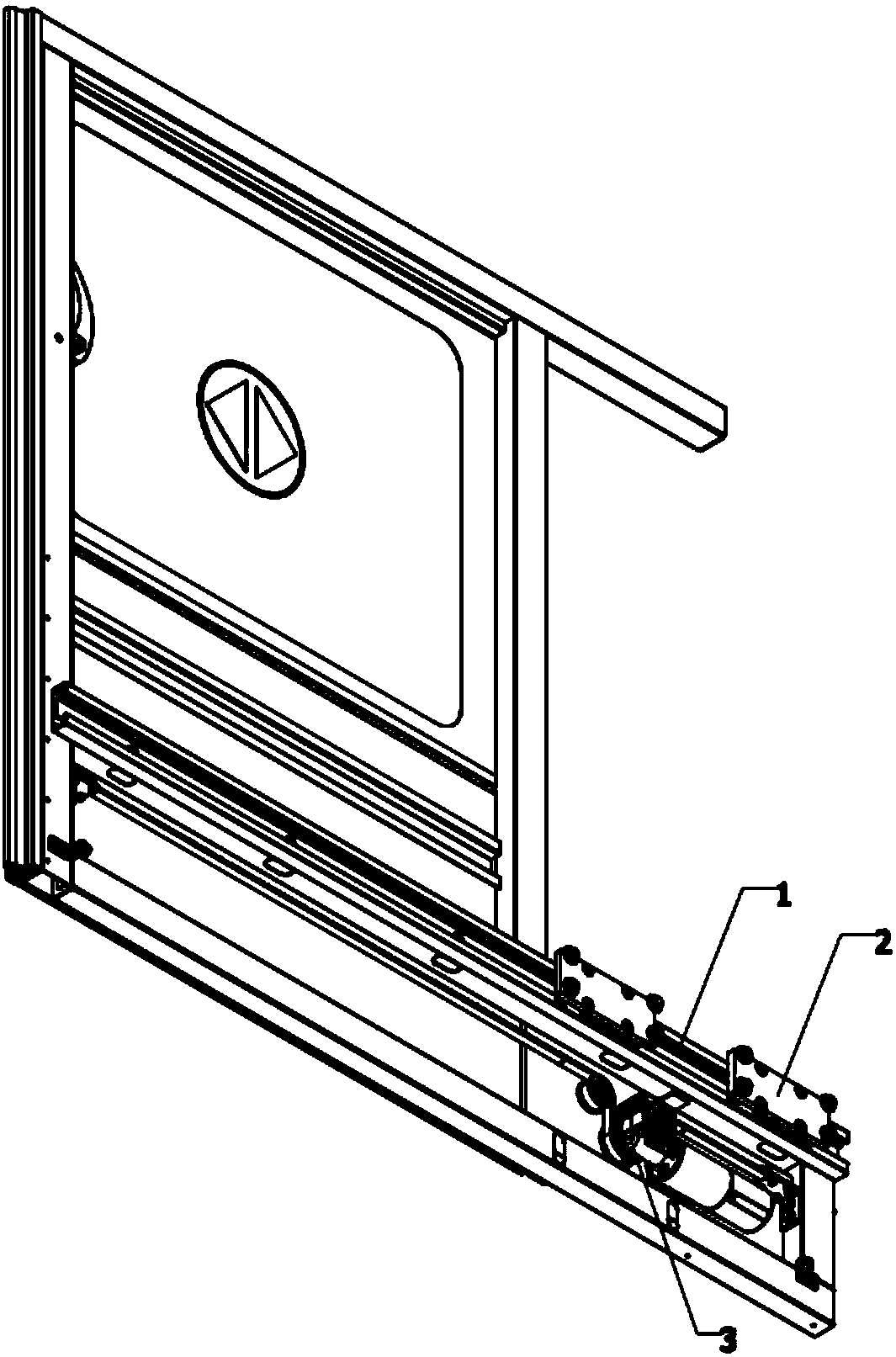

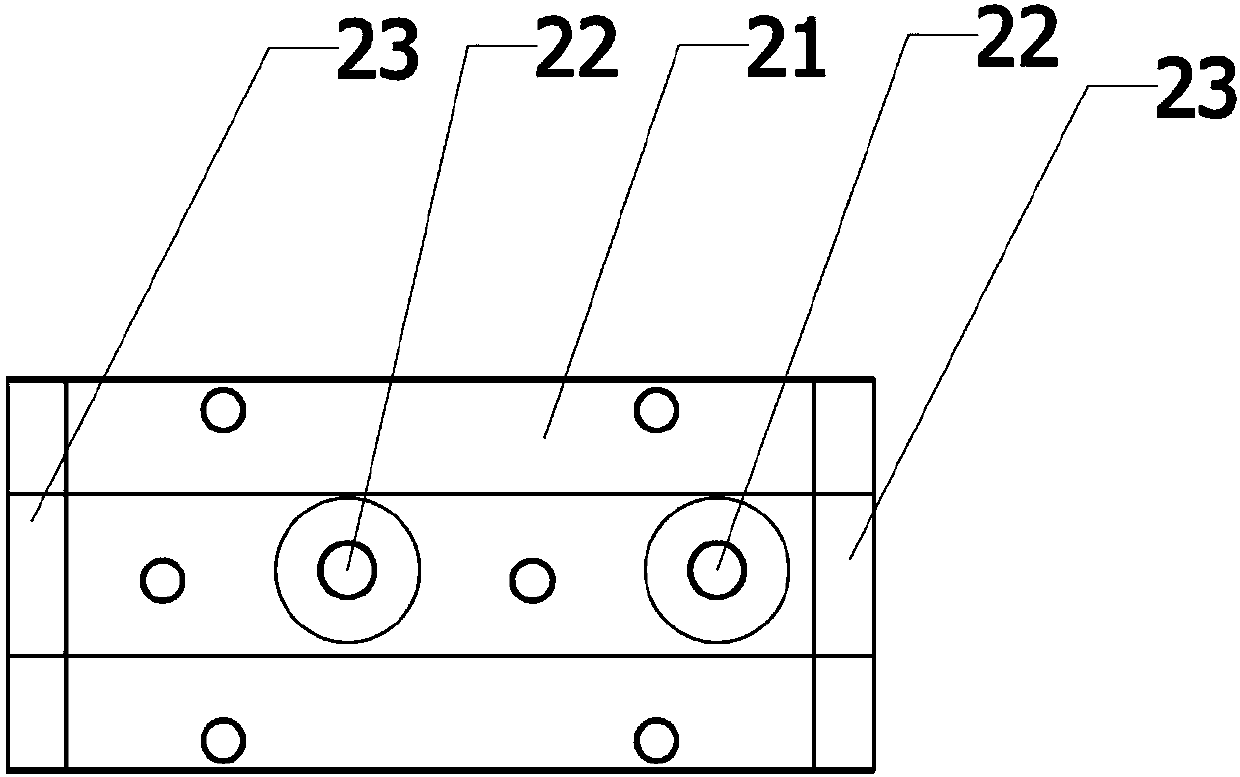

[0026] Such as Figure 1~4 As shown, the present invention provides a half-height door with a roller guide rail device, comprising a sliding door body, a guide rail 1 installed on the sliding door body, two sliders 2 connected with the guide rail 1 and used for driving the guide rail 1 and the sliding door. The drive device 3 for the relative movement of the block 2; the guide rail 1 is a "C-shaped" structure cold-drawn carbon steel material, and the track groove is processed by high-frequency induction quenching and grinding; the slider 2 includes a shell 21, which is installed on the shell 21 The three rollers 22 on the top and the nylon scrapers 23 installed on both sides of the housing 21, the guide rail 1 and the slider 2 are all nickel-plated; the driving device 3 includes a motor 31 fixedly installed on the platform, connected to the motor 31 The driving wheel 32, the tensioning wheel 33 located on both sides of the driving wheel 32 and the belt 34 fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com