Eutectic Bi-Pb-Sn-Cd fusible alloy at temperature of 70 DEG C and method for preparing eutectic Bi-Pb-Sn-Cd fusible alloy

A fusible alloy, bi-pb-sn-cd technology, applied in the field of alloys, can solve problems such as insensitivity and inaccurate operating temperature, and achieve the effects of accurate melting point, accurate melting point operating temperature and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

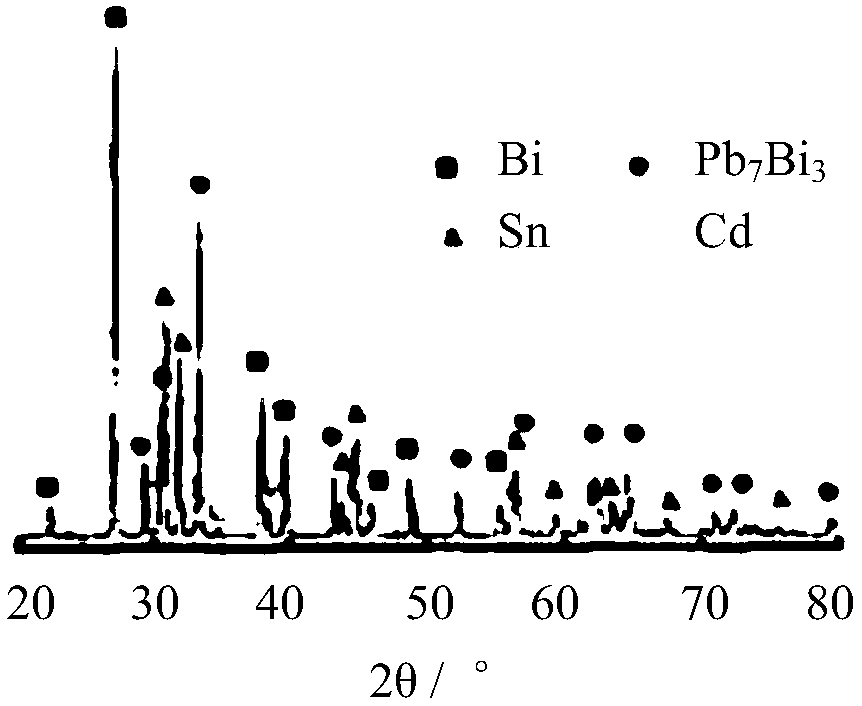

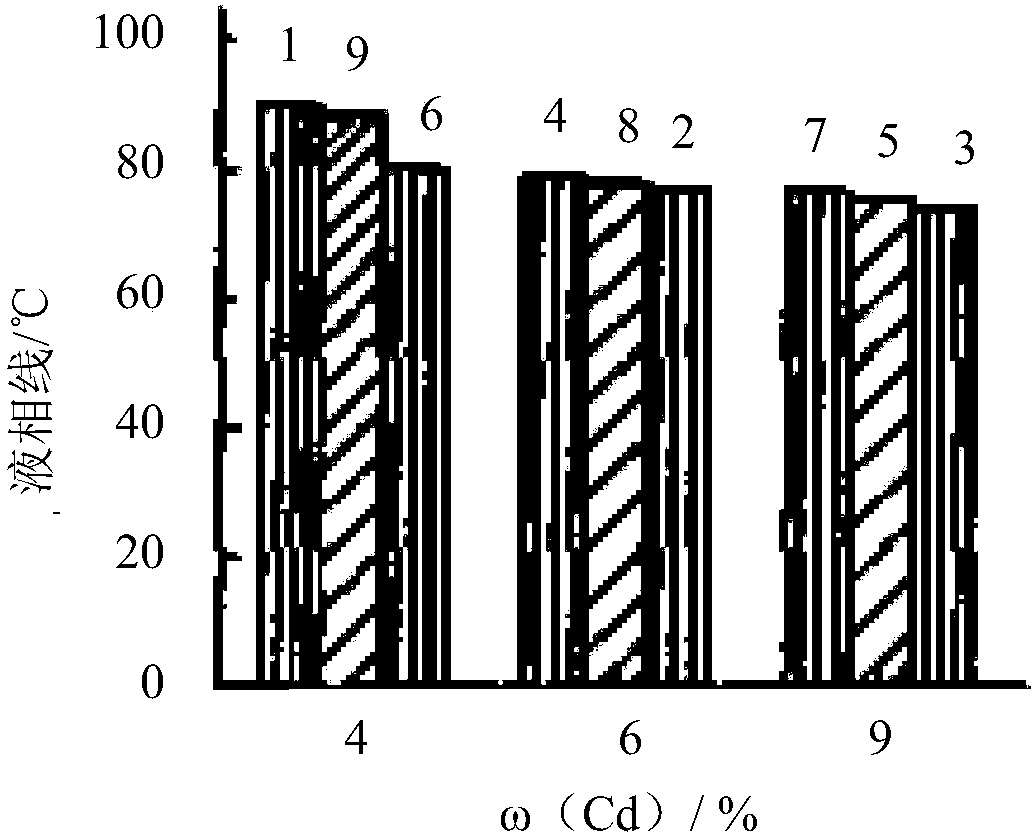

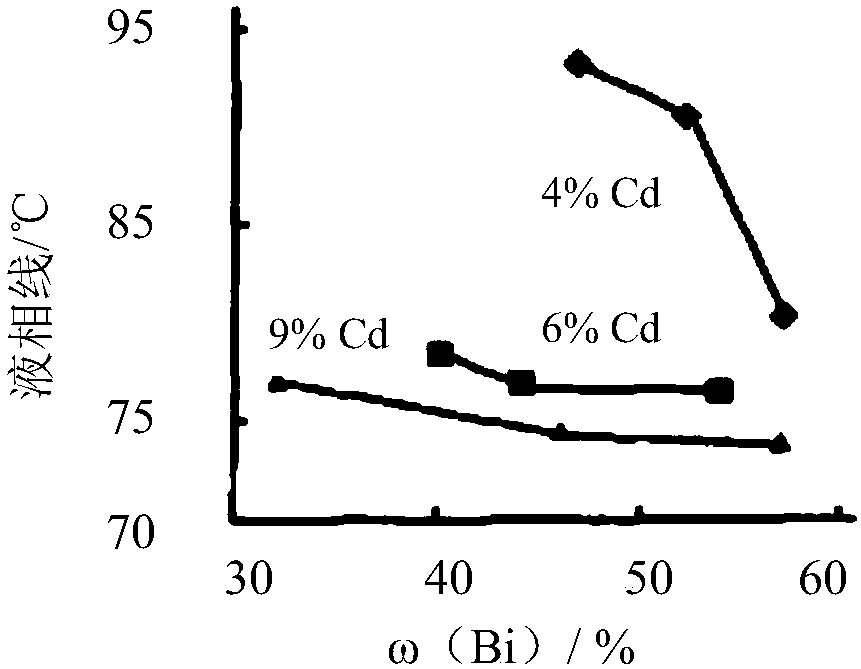

[0022] According to mass percentage, it consists of the following components: Bi 47%, Pb 25%, Sn 24% and Cd 4%. The preparation method includes: weighing Bi, Pb, Sn and Cd in proportion, using a high-frequency heating furnace to melt the alloy under the condition of pre-evacuation and then filling with argon, and controlling the melting temperature at 360°C to obtain Bi - Pb-Sn-Cd fusible alloy, denoted as Alloy 1.

Embodiment 2

[0024] According to mass percentage, it consists of the following components: Bi 54%, Pb 25%, Sn 15% and Cd 6%. The preparation method includes: weighing Bi, Pb, Sn and Cd in proportion, using a high-frequency heating furnace to melt the alloy under the condition of pre-evacuation and then filling with argon, and controlling the melting temperature at 360°C to obtain Bi - Pb-Sn-Cd fusible alloy, denoted as alloy 2.

Embodiment 3

[0026] According to mass percentage, it consists of the following components: Bi 57%, Pb 25%, Sn 9% and Cd 9%. The preparation method includes: weighing Bi, Pb, Sn and Cd in proportion, using a high-frequency heating furnace to melt the alloy under the condition of pre-evacuation and then filling with argon, and controlling the melting temperature at 360°C to obtain Bi -Pb-Sn-Cd fusible alloy, denoted as alloy 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com