Fluoride-contained crosslinked polyether demulsifier and preparation method thereof

A technology of fluorine-containing polyether and demulsifier, which is applied in the direction of chemical dehydration/demulsification, etc. It can solve the problems of unqualified crude oil for export, cannot meet the requirements of rapid treatment, and the on-site treatment process is short, so as to reduce the moisture content and reduce the The effect of interface strength and fast dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

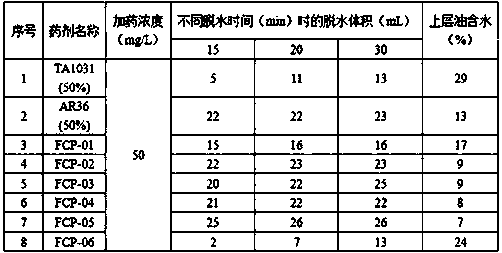

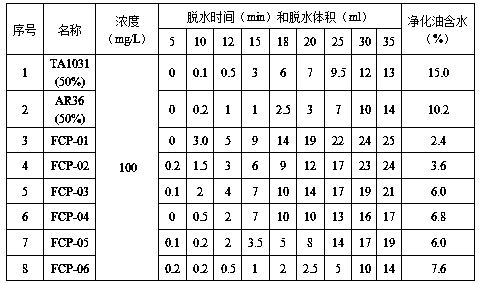

Examples

Embodiment 1

[0019] Embodiment 1 adopts the following steps to realize the present invention:

[0020] (1) Add 100g of 4-fluorophenol and 3g of potassium hydroxide into the high-temperature and high-pressure reactor, heat up to 90°C, vacuum dehydrate for 30min, continue to heat up to about 120°C, gradually introduce 900g of propylene oxide, and control the reaction temperature at 120°C ~140°C, pressure lower than 0.4MPa, after reaction in the kettle to negative pressure, keep the reaction at 130°C for 1 hour, and then get 4-fluorophenol polyoxypropylene ether oil head;

[0021] (2) Take 100g of the 4-fluorophenol polyoxypropylene ether oil head synthesized in step (1) of this example, add 1.2g of potassium hydroxide, heat up to 90°C, vacuum dehydrate for 30min, continue to heat up to about 120°C, gradually 200g of propylene oxide was introduced, and the reaction temperature was controlled at 120-140°C, and the pressure was lower than 0.4MPa. After the reaction in the kettle reached negativ...

Embodiment 2

[0023] Embodiment 2 adopts the following steps to realize the present invention:

[0024] (1) Take 100g of the 4-fluorophenol polyoxypropylene ether oil head synthesized in step (1) of Example 1, put in 2.25g of potassium hydroxide, heat up to 90°C, vacuum dehydrate for 30min, and continue to heat up to about 120°C , gradually feed 400g of propylene oxide, and control the reaction temperature at 120-140°C and the pressure below 0.4MPa. After the reaction in the kettle reaches negative pressure, keep the reaction at 130°C for 1h. When the temperature drops to about 110°C, gradually introduce 250g of ethylene oxide, control the reaction temperature to 110-130°C, and the pressure to be lower than 0.4MPa. After the temperature reaches negative pressure, keep warm for 1 hour to obtain 4-fluorophenol polyoxygen Propylene polyoxyethylene ether (B);

[0025] (2) Take 100 g of 4-fluorophenol polyoxypropylene polyoxyethylene ether (B) synthesized in step (1) of this example and place i...

Embodiment 3

[0026] Embodiment 3 adopts the following steps to realize the present invention:

[0027] (1) Add 100g of 3,4-difluorophenol and 4g of potassium hydroxide into the high-temperature and high-pressure reactor, heat up to 90°C, vacuum dehydrate for 30min, continue to heat up to about 120°C, gradually introduce 900g of propylene oxide, and control The reaction temperature is 120-140°C and the pressure is lower than 0.4MPa. After the reaction in the kettle reaches negative pressure, the reaction is carried out at 130°C for 1 hour to obtain 3,4-difluorophenol polyoxypropylene ether oil head;

[0028] (2) Take 100g of the 3,4-difluorophenol polyoxypropylene ether oil head synthesized in step (1) of this example, add 4g of potassium hydroxide, heat up to 90°C, vacuum dehydrate for 30min, and continue to heat up to about 120°C , gradually feed 700g of propylene oxide, and control the reaction temperature at 120-140°C and the pressure below 0.4MPa. After the reaction in the kettle reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com