Sound-proof modified asphalt waterproof roll and preparation method thereof

A technology of modified asphalt and waterproof membranes, which is applied in building insulation materials, building components, buildings, etc. It can solve the problems of low tensile strength, poor sound insulation, and small elongation, and achieve high elongation at break and sound insulation. Good performance, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing a sound-insulating modified asphalt waterproof membrane, comprising the following steps:

[0048] a) Add tris hydrochloride and surfactant to water, after stirring evenly, adjust the pH value of the solution to 8.5 with sodium hydroxide, and add dopamine hydrochloride, add asphalt after stirring, and stir again After uniformity, stand for 24 hours to obtain modified asphalt;

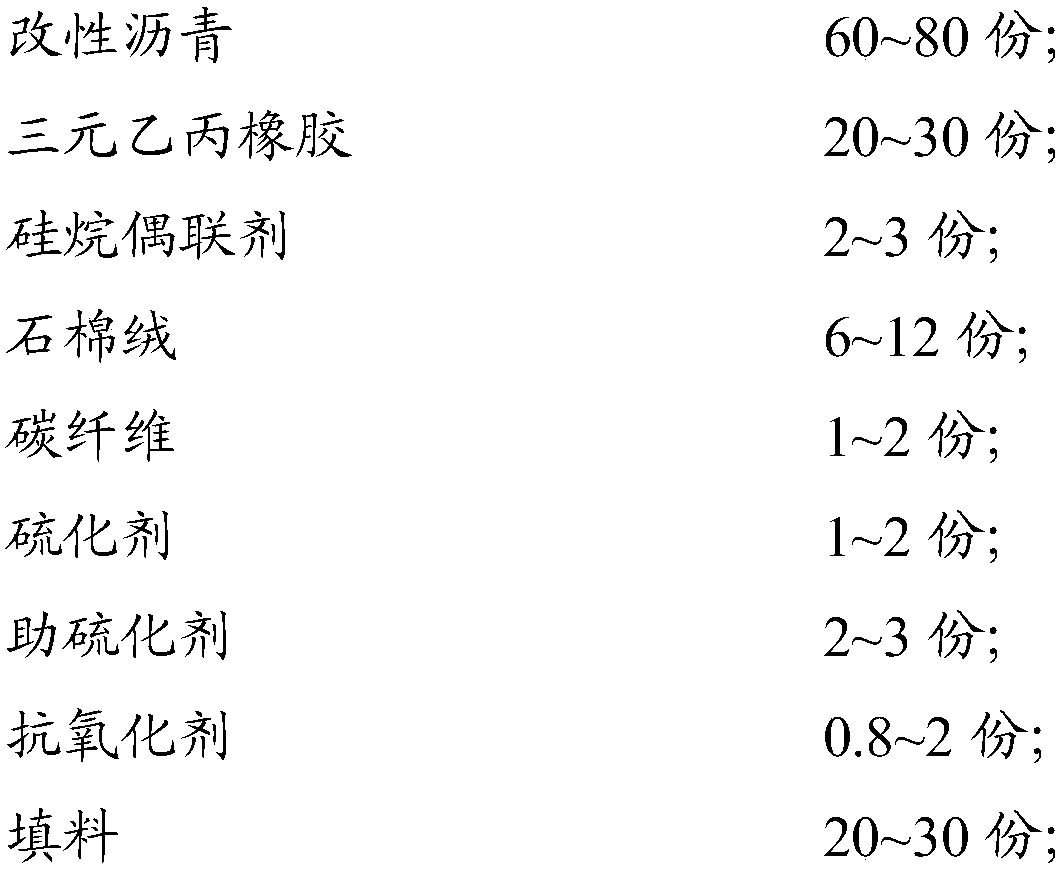

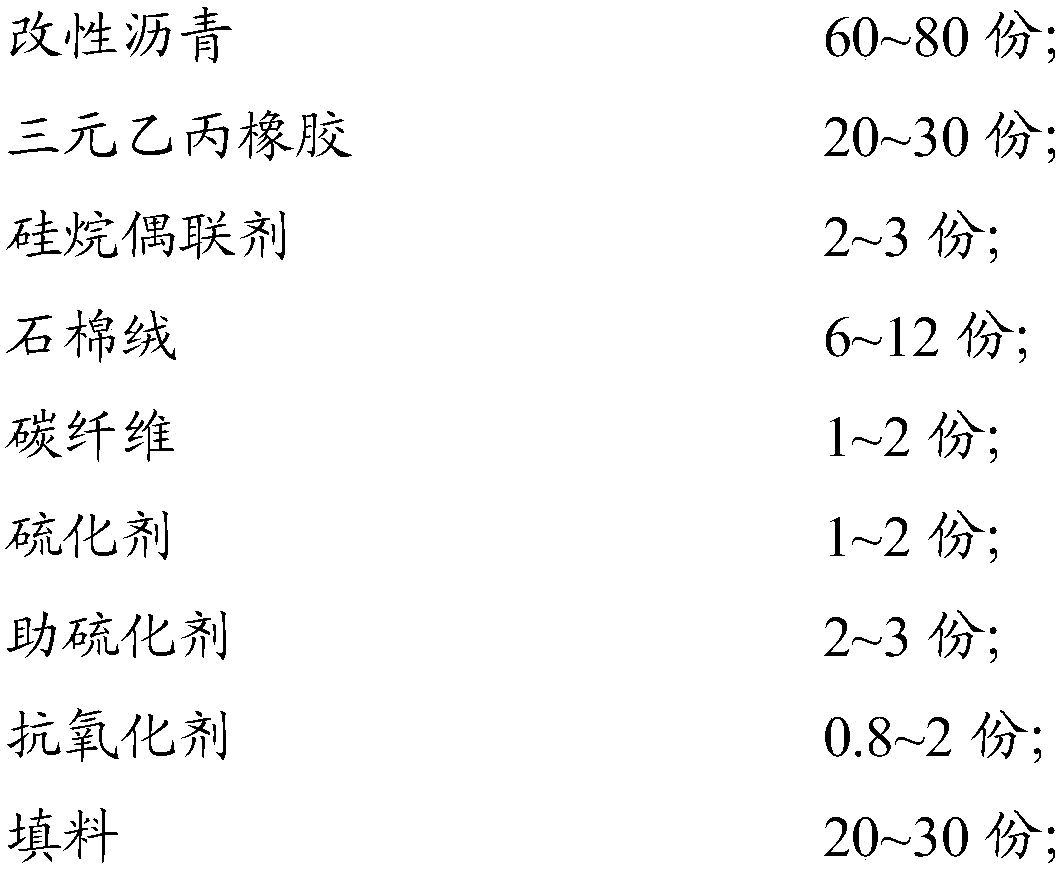

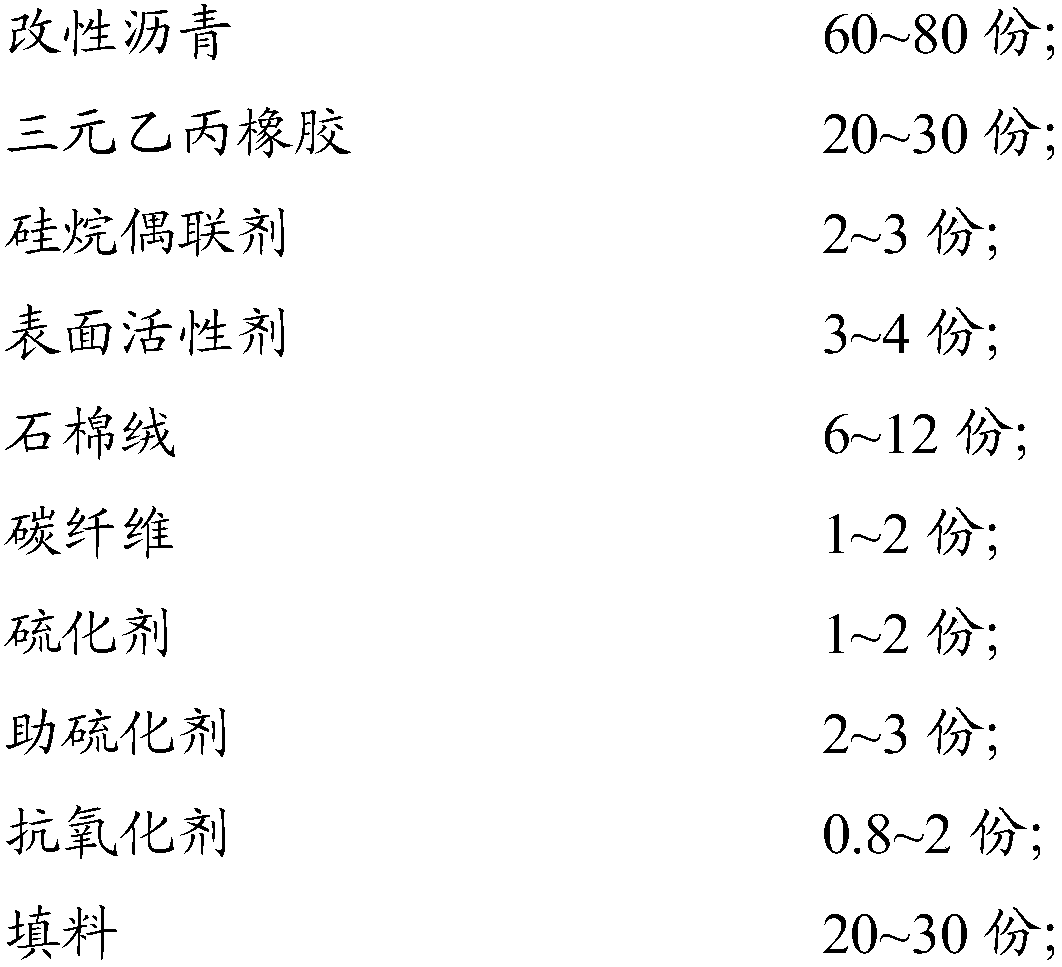

[0049] b) Add the modified asphalt, EPDM rubber, silane coupling agent, asbestos wool, carbon fiber, vulcanizing agent, co-vulcanizing agent, antioxidant, and filler obtained in step a) to a high-speed mixing mixer, and heat the mixture at 50-70°C Stir for 60-100min to obtain the mixture;

[0050] c) Add the mixture obtained in step a) to the rubber mixer for plasticating and then kneading. The kneading temperature is controlled at 80-90°C, and the kneading time is 30-50 minutes. Rolled into a semi-finished waterproof membrane with a thi...

Embodiment 1

[0058] a) Add tris hydrochloride and surfactant to water, after stirring evenly, adjust the pH value of the solution to 8.5 with sodium hydroxide, and add dopamine hydrochloride, add asphalt after stirring, and stir again After uniformity, stand for 24 hours to obtain polydopamine modified asphalt; the mass ratio of water, tris hydrochloride, dopamine hydrochloride, surfactant and asphalt is 30:4:1.5:3:60;

[0059] b) the parts by weight obtained in step a) are 75 parts by weight of modified bitumen, 28 parts by weight of EPDM rubber, 2.8 parts by weight of silane coupling agent, 10 parts by weight The asbestos wool, the carbon fiber of 1.4 parts by weight, the vulcanizing agent of 1.6 parts by weight, the auxiliary vulcanization agent of 2.6 parts by weight, the antioxidant of 0.8 parts by weight, 28 parts by weight The filler, 0.6 parts by weight of anti-ultraviolet agent and 1.1 parts by weight of anti-aging agent were added to a high-speed mixing mixer, and stirred at 60 °...

Embodiment 2

[0063] a) Add tris hydrochloride and surfactant to water, after stirring evenly, adjust the pH value of the solution to 8.5 with sodium hydroxide, and add dopamine hydrochloride, add asphalt after stirring, and stir again After being uniform, stand for 24 hours to obtain polydopamine modified asphalt; the mass ratio of water, tris hydrochloride, dopamine hydrochloride, surfactant and asphalt is 32:3.8:1.7:3.2:62;

[0064] b) the parts by weight obtained in step a) are 65 parts by weight of modified bitumen, 26 parts by weight of EPDM rubber, 2.6 parts by weight of silane coupling agent, 11 parts by weight The asbestos wool, the carbon fiber of 1.6 parts by weight, the vulcanizing agent of 1.8 parts by weight, the auxiliary vulcanization agent of 3 parts by weight, the antioxidant of 1.1 parts by weight, 22 parts by weight The filler, 0.75 parts by weight of anti-ultraviolet agent and 1.3 parts by weight of anti-aging agent are added to a high-speed mixing mixer, and stirred at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com