Method for preparing bismuth oxychloride/bismuth oxyiodide composite ultrathin nanosheets by ion exchange method

An ion exchange method, bismuth oxychloride technology, applied in the field of preparation of bismuth oxychloride/bismuth oxyiodide composite ultra-thin nanosheets by ion exchange method, can solve problems such as limited space for improvement, complicated preparation process, complicated operation, etc., and achieve simple operation Ease of operation, wide photoresponse range, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

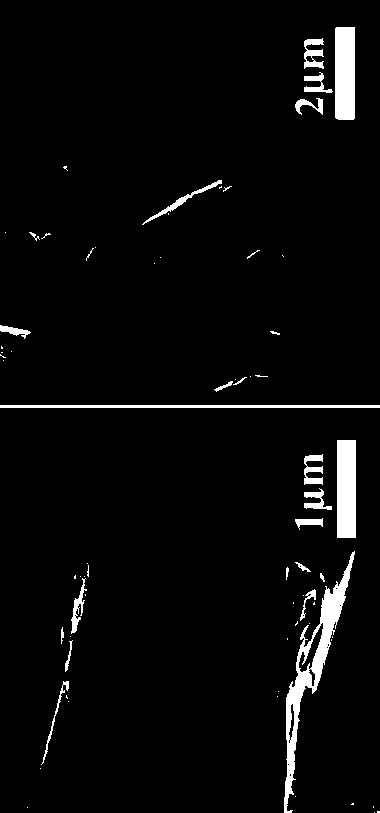

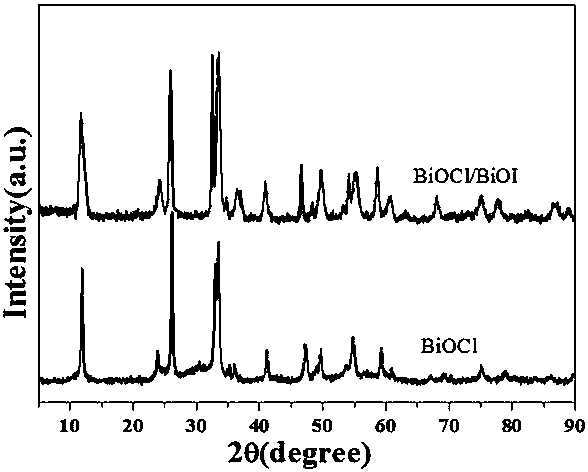

[0014] Dissolve 0.486g of bismuth nitrate pentahydrate and 0.4g of polyvinylpyrrolidone in 25mL of ethylene glycol solution, stir at room temperature until completely dissolved, slowly add 5mL of saturated sodium chloride solution into the above solution, and continue stirring to obtain a white turbid solution. The obtained white turbid solution was transferred to a hydrothermal reaction kettle and reacted at 160°C for 3 hours, cooled to room temperature, centrifuged, and the white precipitate formed by the reaction was washed with deionized water and ethanol respectively, and then vacuum-dried at 60°C to obtain the product bismuth oxychloride super Then take 0.1g of the prepared bismuth oxychloride ultra-thin nanosheets and disperse them into 15mL saturated potassium iodide solution, stir at room temperature for 3h and then vacuum dry at 60°C to obtain the target product bismuth oxychloride / bismuth oxyiodide composite ultrathin Thin nanosheet BOC / BOI-NS1.

Embodiment 2

[0016] Dissolve 0.486g of bismuth nitrate pentahydrate and 0.4g of polyvinylpyrrolidone in 25mL of ethylene glycol solution, stir at room temperature until completely dissolved, slowly add 5mL of saturated sodium chloride solution into the above solution, and continue stirring to obtain a white turbid solution. The obtained white turbid solution was transferred to a hydrothermal reaction kettle and reacted at 160°C for 3 hours, cooled to room temperature, centrifuged, and the white precipitate formed by the reaction was washed with deionized water and ethanol respectively, and then vacuum-dried at 60°C to obtain the product bismuth oxychloride super Thin nanosheets, and then take 0.5g of the prepared bismuth oxychloride ultrathin nanosheets and disperse them in 50mL saturated potassium iodide solution, stir in a water bath at 40°C for 6h, and then vacuum dry at 60°C to obtain the target product bismuth oxychloride / iodine oxide Bismuth composite ultrathin nanosheets BOC / BOI-NS2....

Embodiment 3

[0018] Dissolve 0.486g of bismuth nitrate pentahydrate and 0.4g of polyvinylpyrrolidone in 25mL of ethylene glycol solution, stir at room temperature until completely dissolved, slowly add 5mL of saturated sodium chloride solution into the above solution, and continue stirring to obtain a white turbid solution. The obtained white turbid solution was transferred to a hydrothermal reaction kettle and reacted at 160°C for 3 hours, cooled to room temperature, centrifuged, and the white precipitate formed by the reaction was washed with deionized water and ethanol respectively, and then vacuum-dried at 60°C to obtain the product bismuth oxychloride super Thin nanosheets, and then take 2g of the prepared bismuth oxychloride ultrathin nanosheets and disperse them in 50mL saturated potassium iodide solution, stir in a water bath at 50°C for 12h, and then vacuum dry at 60°C to obtain the target product bismuth oxychloride / bismuth oxyiodide Composite ultrathin nanosheet BOC / BOI-NS3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com