A kind of preparation method of perovskite nano rod

A nanorod, perovskite technology, applied in nanotechnology, nanooptics, nanotechnology, etc., to achieve the effect of shortening the transmission time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

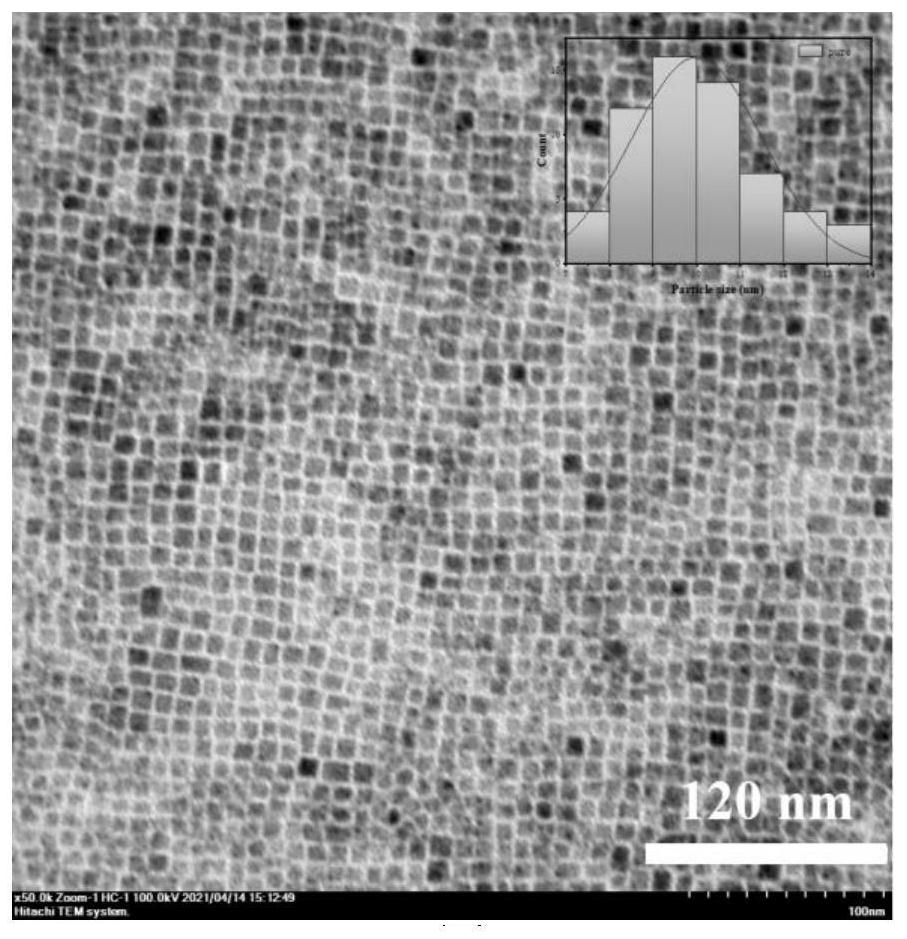

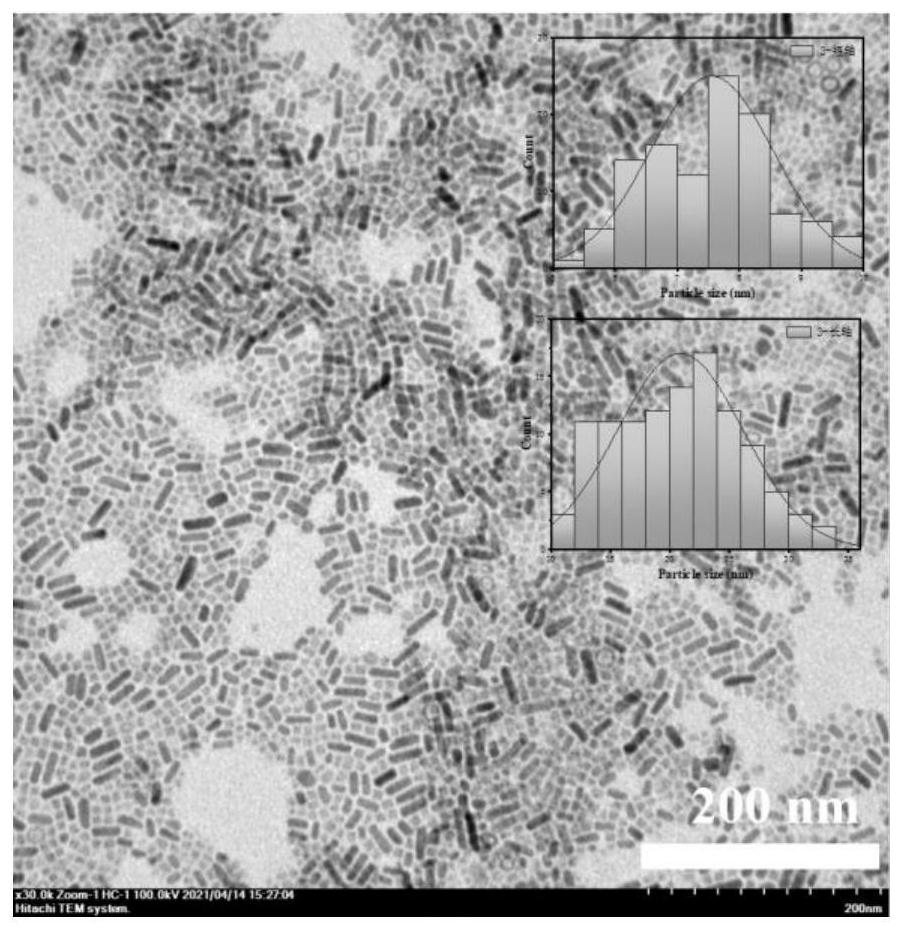

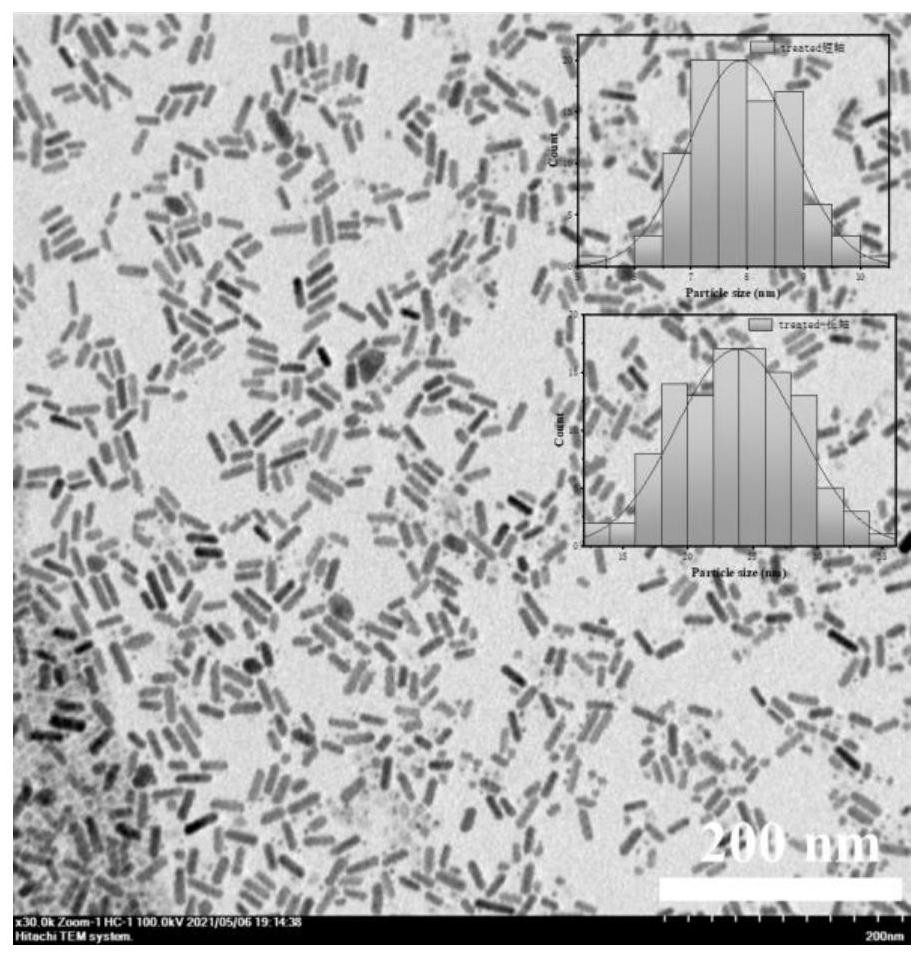

Image

Examples

Embodiment 1

[0032] (1) 0.1mmol of CsCO 3 And 0.2mmol PbO mixed with 10mL of ODE and 1mL of OA, placed in a 100mL three-necked flask. Then the solution was heated to 120°C, and vacuumized at a constant temperature for 30 minutes until it was fully dissolved, and at the same time water and oxygen in the reaction system were removed.

[0033] (2) The temperature was further raised to 180°C, and 1.5mL of OLA-HI was injected, reacted for 10s, cooled with cold water, and the temperature was controlled at 80°C;

[0034] (3) Add 0.064 mmol of tetrabutylammonium fluoride (TBAF) into the flask and stir for 15 min, then let stand for 10 min. Then cool with cold water to terminate the reaction.

[0035] (4) Take out the synthesized mother liquor and place it in a centrifuge tube, centrifuge at 12000rpm for 5min, take the precipitate and dissolve it in toluene; centrifuge again, centrifuge at 8000rpm for 3min, take the supernatant to obtain a perovskite nanorod solution.

Embodiment 2

[0037] (1) 0.1mmol of CsCO 3 And 0.2mmol PbO mixed with 10mL of ODE and 1mL of OA, placed in a 100mL three-necked flask. Then the solution was heated to 120°C, and vacuumized at a constant temperature for 35 minutes until it was fully dissolved, and water and oxygen in the reaction system were removed at the same time.

[0038] (2) The temperature was further raised to 200°C, and 1.5mL of OLA-HI was injected, reacted for 10s and cooled with cold water, and the temperature was controlled at 80°C;

[0039] (3) Add 0.064 mmol of tetrabutylammonium fluoride (TBAF) into the flask and stir for 15 min, then let stand for 10 min. Then cool with cold water to terminate the reaction.

[0040] (4) Take out the synthesized mother liquor and place it in a centrifuge tube, centrifuge at 12000rpm for 5min, take the precipitate and dissolve it in toluene; centrifuge again, centrifuge at 8000rpm for 3min, take the supernatant to obtain a perovskite nanorod solution.

Embodiment 3

[0042] (1) 0.1mmol of CsCO 3 And 0.2mmol PbO mixed with 10mL of ODE and 1mL of OA, placed in a 100mL three-necked flask. Then the solution was heated to 120°C, and vacuumized at a constant temperature for 30 minutes until it was fully dissolved, and at the same time water and oxygen in the reaction system were removed.

[0043] (2) The temperature was further raised to 180°C, and 1.5mL of OLA-HI was injected, reacted for 10s, cooled with cold water, and the temperature was controlled at 80°C;

[0044] (3) Add 0.064 mmol of ethyl difluoroacetoacetate to the flask and stir for 15 min, then let stand for 10 min. Then cool with cold water to terminate the reaction.

[0045] (4) Take out the synthesized mother liquor and place it in a centrifuge tube, centrifuge at 12000rpm for 5min, take the precipitate and dissolve it in toluene; centrifuge again, centrifuge at 8000rpm for 3min, take the supernatant to obtain a perovskite nanorod solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com